Modern electrical distribution systems require precise sealing solutions to maintain operational efficiency and safety standards. The evolution of automated sealing technology has transformed how manufacturers approach gasket application in electrical panels and enclosures. Advanced machinery now enables consistent, high-quality sealing that meets stringent industry requirements while reducing production time and material waste. This technological advancement has become essential for companies seeking competitive advantages in electrical manufacturing markets.

Understanding Modern Sealing Technology in Electrical Manufacturing

Evolution of Automated Sealing Solutions

The electrical manufacturing industry has witnessed remarkable transformation in sealing technology over the past decade. Traditional manual gasket application methods often resulted in inconsistent seal quality, leading to potential ingress protection failures and costly warranty claims. Modern automated systems address these challenges through precision-controlled dispensing mechanisms that ensure uniform gasket placement across various panel configurations.

Contemporary sealing machinery incorporates advanced control systems that monitor dispensing pressure, temperature, and material flow rates in real-time. These sophisticated monitoring capabilities enable manufacturers to maintain consistent seal quality while adapting to different substrate materials and environmental conditions. The integration of digital feedback systems has significantly improved process reliability and reduced material consumption.

Material Compatibility and Performance Standards

Polyurethane foam gaskets have emerged as the preferred sealing material for electrical distribution boards due to their excellent compression characteristics and long-term stability. These materials provide superior resistance to environmental factors including moisture, dust, and temperature variations that commonly affect electrical enclosures. The cellular structure of polyurethane foam enables effective sealing even when panel tolerances vary within manufacturing specifications.

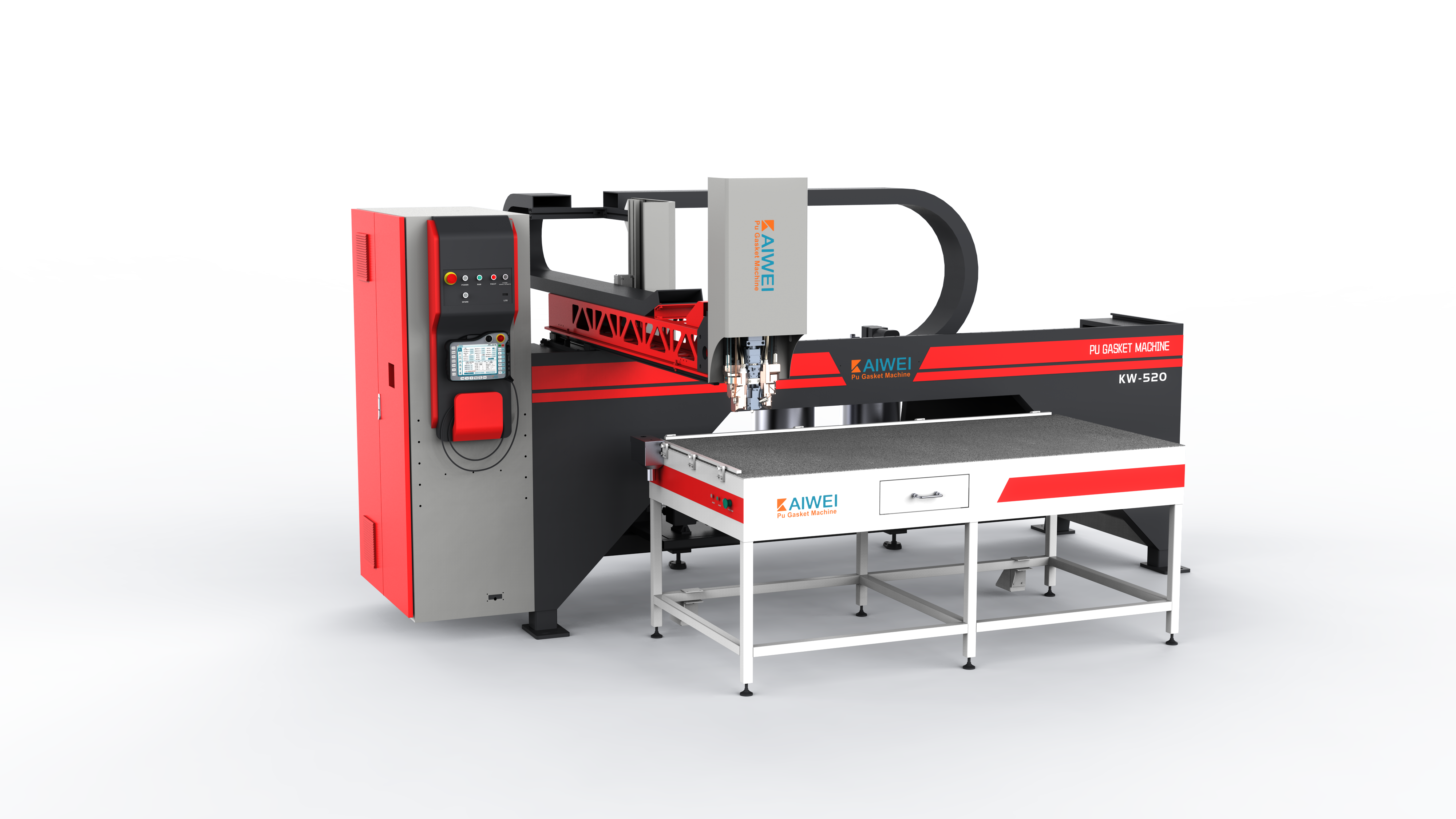

Modern Gasket Machine systems are specifically designed to handle various polyurethane formulations while maintaining optimal dispensing characteristics. The ability to process different material viscosities and cure times provides manufacturers with flexibility in selecting materials that best match their specific application requirements and performance standards.

Technical Specifications and Operational Capabilities

Precision Control Systems

Advanced gasket dispensing equipment features programmable logic controllers that enable precise control over multiple operational parameters. These systems can store and recall hundreds of different dispensing programs, allowing manufacturers to quickly switch between various panel designs without extensive setup procedures. The programming capability extends to complex gasket patterns including corners, intersections, and custom geometries that match specific electrical enclosure designs.

Temperature control represents another critical aspect of modern sealing machinery. Integrated heating systems maintain optimal material temperature throughout the dispensing process, ensuring consistent flow characteristics and proper adhesion to substrate surfaces. Advanced temperature monitoring prevents material degradation while optimizing cure times for maximum production efficiency.

Production Efficiency and Quality Metrics

Contemporary gasket application systems achieve remarkable production rates while maintaining stringent quality standards. Typical processing speeds range from 30 to 100 millimeters per second, depending on gasket complexity and material requirements. These speeds represent significant improvements over manual application methods while providing superior consistency in seal placement and thickness.

Quality monitoring systems continuously evaluate gasket placement accuracy, material distribution, and adhesion characteristics. Real-time feedback mechanisms alert operators to potential issues before they affect product quality, enabling immediate corrective actions. Statistical process control capabilities provide comprehensive documentation of production parameters, supporting quality certification requirements and continuous improvement initiatives.

Industry Applications and Market Segments

Electrical Panel Manufacturing

Electrical distribution board manufacturers represent the primary market segment for advanced gasket sealing technology. These manufacturers require sealing solutions that meet specific ingress protection ratings while maintaining cost-effective production processes. Modern machinery enables consistent achievement of IP54, IP65, and higher protection levels through precise gasket placement and optimal material selection.

The versatility of contemporary sealing equipment accommodates various panel sizes and configurations, from compact residential distribution boards to large industrial control panels. This adaptability enables manufacturers to standardize their sealing processes across diverse product lines while maintaining the flexibility to accommodate custom specifications and special applications.

Emerging Market Opportunities

Renewable energy infrastructure development has created substantial demand for high-quality electrical enclosures with reliable sealing systems. Solar inverter housings, wind turbine control panels, and energy storage system enclosures all require superior ingress protection to ensure long-term reliability in challenging environmental conditions. Advanced gasket machinery provides the precision and consistency necessary for these demanding applications.

Smart grid technology implementation further expands market opportunities for specialized sealing solutions. Remote monitoring equipment, automated switching devices, and distributed energy resources all require enclosures with exceptional sealing performance to maintain operational reliability over extended service periods. The ability to achieve consistent sealing quality becomes increasingly important as grid infrastructure becomes more distributed and automated.

Economic Benefits and Return on Investment

Cost Reduction Strategies

Automated gasket application systems deliver substantial cost reductions through multiple mechanisms including reduced material waste, improved production efficiency, and decreased labor requirements. Traditional manual sealing methods often result in material waste rates exceeding 15 percent due to inconsistent application and operator variability. Modern machinery typically reduces waste to less than 3 percent through precise dispensing control and automated material handling.

Labor cost reductions represent another significant economic benefit of automated sealing technology. A single operator can typically manage multiple gasket machines simultaneously, increasing overall production capacity while reducing per-unit labor costs. The consistency of automated systems also eliminates the need for extensive quality inspection procedures, further reducing labor requirements and associated costs.

Quality Improvement and Warranty Reduction

Consistent gasket quality directly translates to reduced warranty claims and improved customer satisfaction. Field failures related to ingress protection issues can result in significant costs including replacement parts, service calls, and potential liability exposure. Advanced sealing machinery minimizes these risks through superior process control and consistent material application.

The documentation capabilities of modern gasket machines provide comprehensive traceability for quality assurance purposes. Detailed production records enable manufacturers to identify and address potential issues before they affect delivered products. This proactive approach to quality management supports continuous improvement initiatives while reducing overall quality-related costs.

Selection Criteria and Implementation Considerations

Technical Requirements Assessment

Selecting appropriate gasket application equipment requires careful evaluation of production requirements, material compatibility, and quality standards. Manufacturing volume projections guide selection of machine capacity and automation level, while product specifications determine necessary precision and repeatability characteristics. Environmental factors including temperature, humidity, and ventilation requirements also influence equipment selection decisions.

Integration with existing production systems represents another important consideration during equipment selection. Modern gasket machines typically feature standard communication interfaces that enable integration with manufacturing execution systems, quality management databases, and predictive maintenance programs. This connectivity supports overall production efficiency while providing comprehensive process visibility.

Training and Support Requirements

Successful implementation of advanced gasket machinery requires comprehensive operator training and ongoing technical support. Equipment manufacturers typically provide initial training programs that cover machine operation, maintenance procedures, and troubleshooting techniques. Advanced training modules address programming capabilities, process optimization, and quality improvement strategies.

Maintenance support and spare parts availability represent critical factors in long-term equipment performance. Preventive maintenance programs extend equipment life while minimizing unexpected downtime. Remote diagnostic capabilities enable proactive maintenance scheduling and rapid resolution of technical issues, supporting consistent production operations.

FAQ

What maintenance requirements are typical for automated gasket machines

Regular maintenance for gasket machines includes daily cleaning of dispensing heads, weekly lubrication of mechanical components, and monthly calibration of control systems. Material system components require periodic flushing to prevent contamination, while pneumatic systems need regular filter replacement and pressure verification. Most manufacturers recommend quarterly professional inspections to ensure optimal performance and identify potential issues before they affect production.

How do gasket machines handle different panel sizes and configurations

Modern gasket machines feature adjustable fixtures and programmable positioning systems that accommodate various panel dimensions and gasket patterns. Quick-change tooling systems enable rapid reconfiguration for different products, while stored programs eliminate setup time for repeat orders. Advanced machines can automatically adjust dispensing parameters based on panel geometry, ensuring consistent gasket quality across diverse product lines.

What quality standards can be achieved with automated gasket application

Automated gasket machines typically achieve ingress protection ratings from IP54 to IP67 or higher, depending on material selection and application parameters. Process control capabilities ensure gasket placement accuracy within ±0.5 millimeters, while consistent material distribution provides uniform sealing performance. Quality documentation systems track all relevant parameters, supporting certification requirements and continuous improvement initiatives.

How does material cost compare between manual and automated gasket application

Automated systems typically reduce material costs by 12-18 percent compared to manual application methods. This reduction results from precise dispensing control that minimizes waste, optimized gasket patterns that reduce material usage, and consistent application that eliminates rework requirements. Additional savings result from reduced inspection costs and lower warranty claim rates due to improved seal quality and reliability.