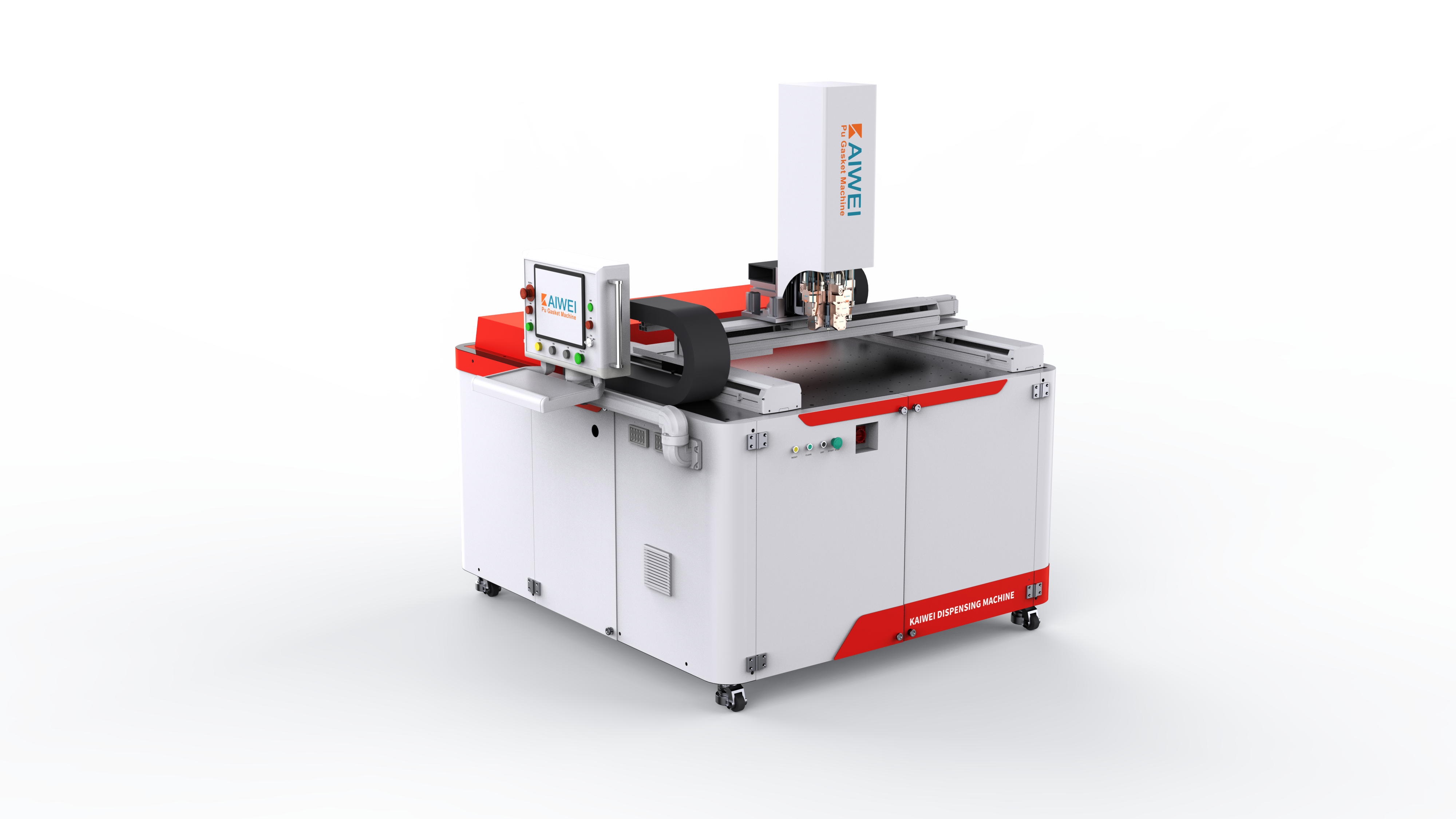

Revolutionizing Industrial Sealing with Advanced Automation

In today's competitive manufacturing landscape, precision and efficiency are paramount to success. PU gasket sealing machines have emerged as game-changing solutions that transform how industries approach sealing applications. These sophisticated systems combine cutting-edge technology with remarkable versatility to deliver consistent, high-quality results while significantly reducing production time and material waste.

The implementation of automated sealing solutions has become increasingly critical as manufacturers face mounting pressure to optimize their operations. PU gasket sealing machines stand at the forefront of this technological revolution, offering unprecedented control over gasket application processes and ensuring exceptional accuracy in even the most demanding environments.

Core Components and Technological Features

Advanced Dispensing Systems

The heart of modern PU gasket sealing machines lies in their sophisticated dispensing mechanisms. These systems utilize precision-engineered pumps and nozzles that ensure consistent material flow and application. The automated dispensing controls maintain optimal pressure and temperature throughout the sealing process, resulting in uniform gasket profiles and superior adhesion properties.

Enhanced with smart monitoring capabilities, these dispensing systems can automatically adjust parameters in real-time, responding to variations in material viscosity or environmental conditions. This level of control significantly reduces the likelihood of defects and ensures consistent quality across production runs.

Programmable Motion Control

PU gasket sealing machines incorporate advanced motion control systems that enable precise movement along predetermined paths. The integration of servo motors and sophisticated control algorithms allows for smooth, accurate dispensing patterns that can be easily customized for different product specifications.

These systems can store multiple program profiles, making it simple to switch between different gasket designs without lengthy setup times. The precision of modern motion control systems ensures that gasket placement remains consistent within microns, meeting the most stringent quality requirements.

Operational Benefits and Production Advantages

Enhanced Production Speed and Efficiency

The implementation of PU gasket sealing machines dramatically accelerates production capabilities compared to manual application methods. These systems can operate continuously at high speeds while maintaining precise control over material dispensing. The automated nature of the process eliminates the need for frequent stops and adjustments, resulting in significantly higher throughput.

Moreover, these machines can handle complex sealing patterns with ease, executing intricate designs that would be challenging or impossible to achieve manually. The combination of speed and precision leads to substantial improvements in overall production efficiency.

Quality Consistency and Waste Reduction

One of the most significant advantages of PU gasket sealing machines is their ability to maintain consistent quality standards throughout extended production runs. The automated system ensures that each gasket is applied with identical pressure, thickness, and positioning, eliminating the variations inherent in manual application processes.

The precise control over material dispensing also results in minimal waste, as these machines can calculate and apply exactly the required amount of sealant for each application. This optimization of material usage not only reduces costs but also contributes to more sustainable manufacturing practices.

Integration and Industry Applications

Manufacturing Process Integration

Modern PU gasket sealing machines are designed to seamlessly integrate into existing production lines. These systems can be configured to work alongside other automated equipment, creating efficient manufacturing cells that optimize workflow and reduce handling requirements. The integration capabilities extend to industry-standard communication protocols, allowing for real-time data exchange and production monitoring.

The adaptability of these machines enables manufacturers to implement them across various production scenarios, from high-volume standardized products to customized, small-batch applications. This flexibility makes them valuable assets in diverse industrial settings.

Industry-Specific Applications

The versatility of PU gasket sealing machines makes them indispensable across numerous industries. In automotive manufacturing, these systems excel in applying precise seals for electronics enclosures, lighting assemblies, and various component housings. The electronics industry relies on these machines for creating protective seals in consumer devices and industrial equipment.

In the HVAC sector, PU gasket sealing machines provide consistent sealing solutions for air handling units and ventilation systems. The ability to maintain tight tolerances and create complex sealing patterns makes these machines equally valuable in aerospace and medical device manufacturing.

Maintenance and Optimization Strategies

Preventive Maintenance Protocols

To ensure optimal performance and longevity of PU gasket sealing machines, implementing comprehensive maintenance protocols is essential. Regular inspection and cleaning of dispensing components prevent material buildup and maintain precise flow control. Systematic checking of motion control systems, including belts, bearings, and guide rails, ensures continued accuracy in gasket placement.

Documentation of maintenance activities and performance metrics helps identify potential issues before they impact production. This proactive approach to maintenance minimizes downtime and extends the operational life of the equipment.

Performance Optimization Techniques

Maximizing the efficiency of PU gasket sealing machines involves continuous monitoring and adjustment of operational parameters. Regular calibration of dispensing systems ensures consistent material flow rates and pressure levels. Analysis of production data helps identify opportunities for cycle time reduction and process improvement.

Training operators in best practices and troubleshooting procedures enables quick resolution of common issues and optimal machine utilization. Implementation of preventive maintenance schedules and regular software updates keeps systems running at peak performance.

Frequently Asked Questions

What factors influence the selection of a PU gasket sealing machine?

Key considerations include production volume requirements, complexity of sealing patterns, required accuracy levels, and integration capabilities with existing manufacturing processes. Additional factors include available floor space, budget constraints, and specific industry compliance requirements.

How long does it take to set up and program a new sealing pattern?

Setup time varies depending on pattern complexity, but modern PU gasket sealing machines typically allow for quick programming through intuitive interfaces. Most standard patterns can be programmed within hours, while more complex applications might require a day or two for optimization.

What are the typical maintenance requirements for these machines?

Regular maintenance includes daily cleaning of dispensing components, weekly inspection of motion systems, and monthly calibration checks. More comprehensive maintenance, including software updates and system overhauls, is typically scheduled quarterly or annually based on usage patterns and manufacturer recommendations.