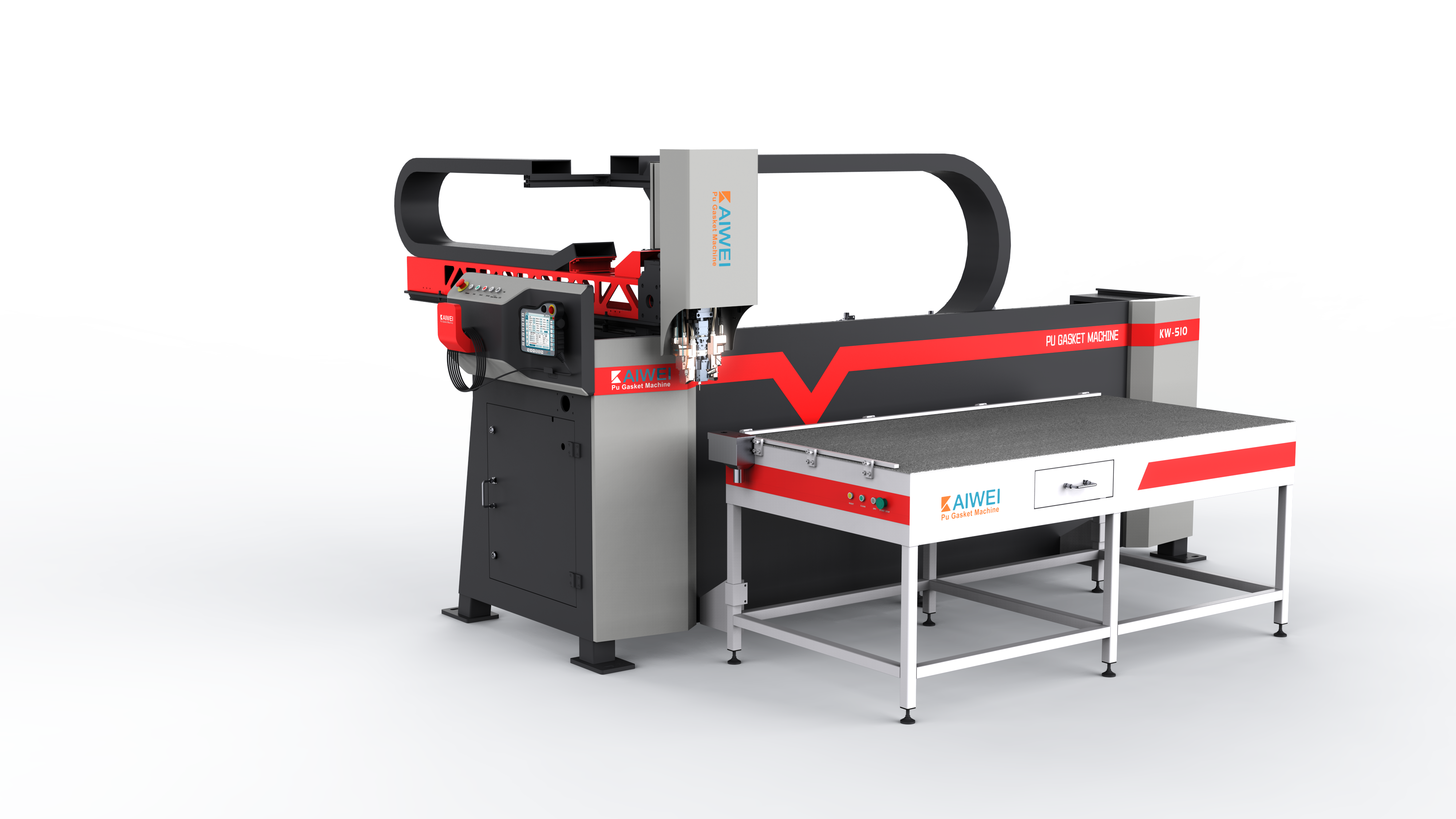

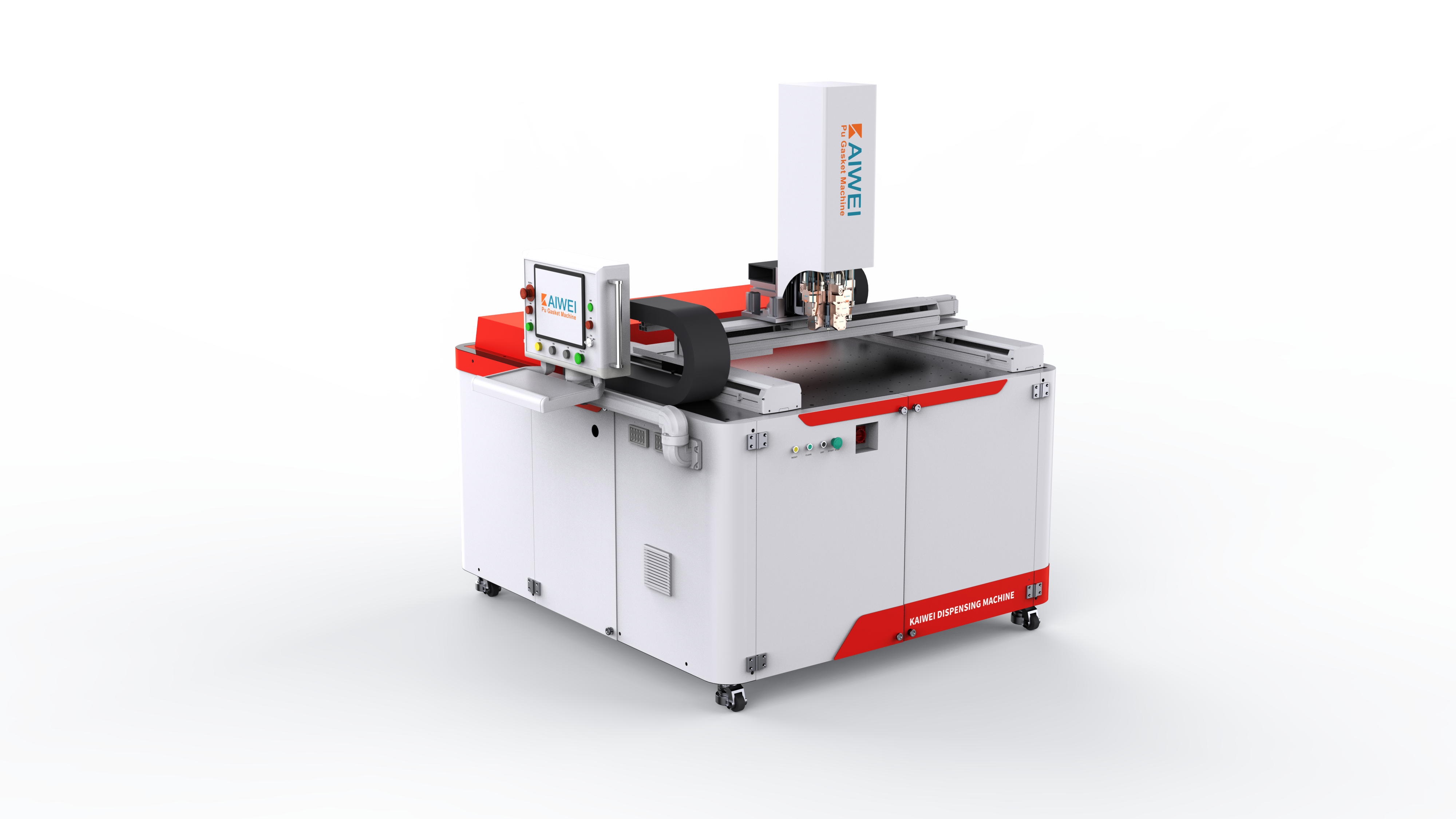

pu pakkauskone käytettävänä

Myydään PU-tiivistyslaitetta, joka on huippuluokan ratkaisu korkealaatuisten polyuretaanitiivisteiden ja -tiivistysten valmistukseen monilla teollisuuden aloilla. Tämä edistynyt laitteisto yhdistää tarkan konetekniikan ja kehittynyttä automaatioteknologiaa tuottaakseen johdonmukaisia, luotettavia tiivistyskomponentteja, jotka täyttävät tiukat laatuvaatimukset. Laitteen toiminta perustuu tarkasti ohjattuun annostelujärjestelmään, joka soveltaa nestemäistä polyuretaanimateriaalia alustalle erinomaisella tarkkuudella ja toistettavuudella. Nykyaikaiset myydään PU-tiivistyslaitteet sisältävät tietokoneohjatut ohjausjärjestelmät, joilla käyttäjät voivat ohjelmoida monimutkaisia tiivisteprofiileja, säätää annosteluparametreja ja seurata tuotannon laatua reaaliajassa. Pääasialliset toiminnot sisältävät automatisoidun materiaalin sekoittamisen, tarkan annostelureitin ohjauksen, lämpötilan säädön ja kovetusprosessin hallinnan. Nämä laitteet ovat erinomaisia erilaisten tiivistetyyppien valmistuksessa, mukaan lukien O-renkaat, muotoiltut tiivisteet, autoteollisuuden tiivisteet, elektroniikkakotelointien tiivisteet ja teollisuuskoneiden tiivisteet. Tekniset ominaisuudet kattavat servohydrauliikkeillä varustetut annostuspäät, ohjelmoitavat logiikkakontrollerit, kosketusnäytöt ja integroidut laadunvalvontajärjestelmät. Edistyneemmät mallit sisältävät kuva-analyysijärjestelmät automaattiseen alustantunnistukseen ja asennon vahvistamiseen. Annostelujärjestelmä ylläpitää johdonmukaista materiaalivirtaa samalla kun se sopeutuu erilaisiin viskositeetteihin ja kovetusajoille. Lämpötilansäätömoduulit varmistavat optimaaliset materiaaliominaisuudet koko annostelu- ja kovetusprosessin ajan. Sovelluskohteita on autoteollisuuden valmistuksessa, elektroniikkakokoonpanossa, kodinkoneiden tuotannossa, ilmanvaihto- ja jäähdytysjärjestelmissä sekä teollisuuslaitteiden valmistuksessa. Laitteet käsittelevät erilaisia alustamateriaaleja, kuten metalleja, muoveja, komposiitteja ja lasipintoja. Tuotantokapasiteetti vaihtelee pienistä protyypiserioista suurten sarjojen valmistukseen, mikä tekee myytävästä PU-tiivistyslaitteesta sopivan eri kokoisille yrityksille. Laitteisto tukee sekä paikalleen muodostettuja tiivisteitä että esimuotoiltujen tiivisteiden valmistusta, tarjoten joustavuutta erilaisten tuotantovaatimusten ja asiakasspesifikaatioiden täyttämiseksi.