uv-digitaalitulostimen hinta

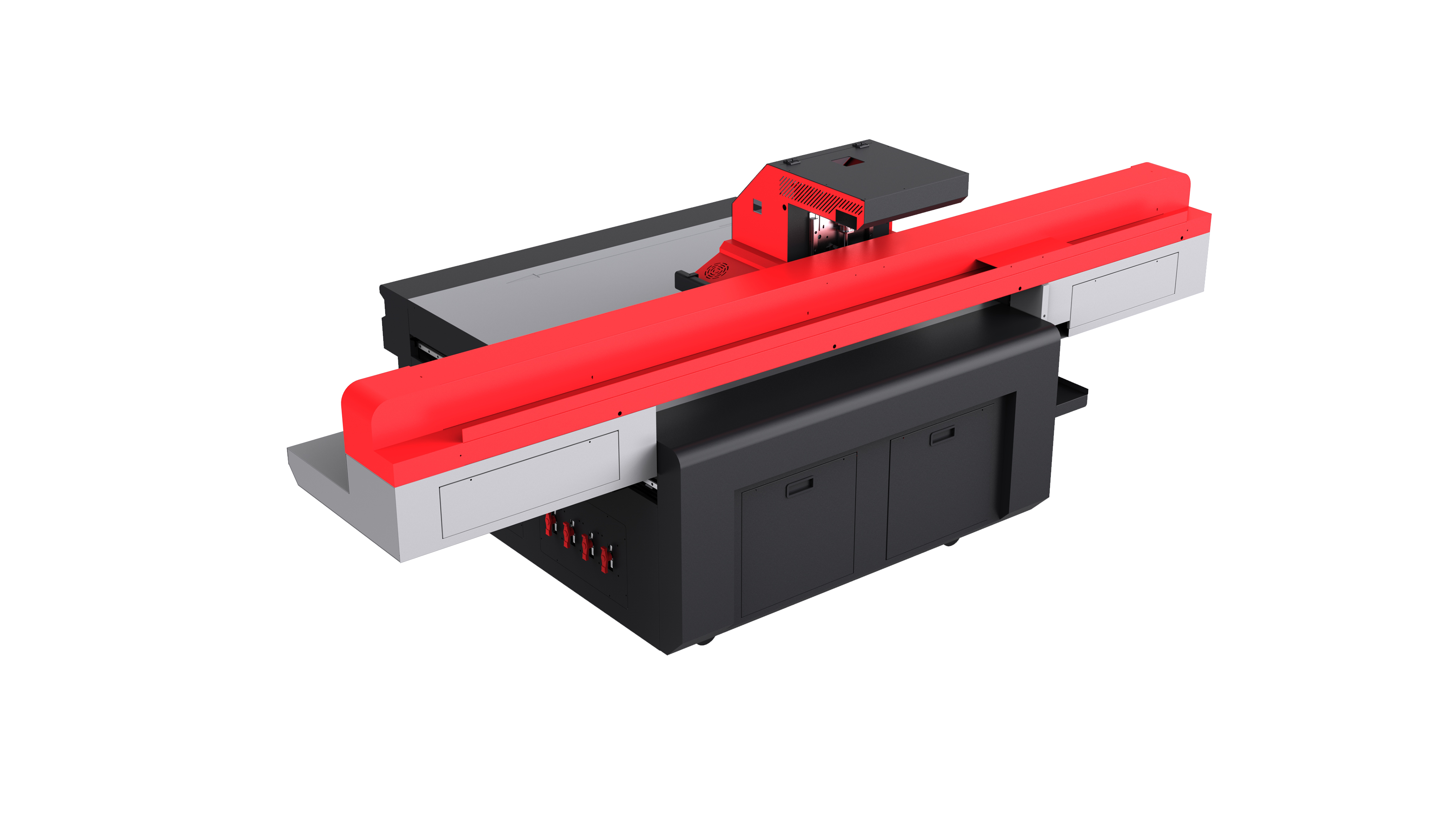

UV-digitaalitulostimien hintatason ymmärtämiseksi on tehtävä kattava tarkastelu näiden järjestelmien tarjoamasta kehittyneestä teknologiasta ja ominaisuuksista. Nykyaikaiset UV-digitaalitulostimet edustavat vallankumouksellista edistystä kaupallisessa painoteknologiassa, tarjoten erinomaista monipuolisuutta ja laatua useilla sovellusaloilla. UV-digitaalitulostimen hinta vaihtelee tyypillisesti alkuarvoisista malleista noin 15 000 dollarista pöytämallien osalta aina yli 500 000 dollarin teollisuusluokan järjestelmiin saakka, mikä heijastaa nykyisen markkinatarjonnan laajaa toiminnallisuutta ja tuotantokapasiteettia. Nämä koneet käyttävät ultraviolettikuivatusmenetelmää kuivatakseen ja kovettaakseen erityisesti muotoiltuja musteita välittömästi, mahdollistaen tulostamisen laajalla alustavalikoimalla, kuten lasi, metalli, puu, muovi, nahka, keramiikka ja tekstiilit. Keskeisiin teknologisiin ominaisuuksiin kuuluvat tarkkuusruiskutulostimet, jotka pystyvät toimittamaan resoluutioita jopa 1440 DPI, edistyneet värienhallintajärjestelmät, jotka tukevat useita musteyhdistelmiä, sekä kehittyneet alustan käsittelymekanismit, jotka sopivat eri paksuisille ja mitoille materiaaleille. Muuttuvan datan tulostusmahdollisuudet mahdollistavat personoidun sisällön luomisen, kun taas valkoisen musteen ja lakaisun vaihtoehdot laajentavat merkittävästi luovia mahdollisuuksia. UV-digitaalitulostimien hinta heijastaa integroituja ohjausjärjestelmiä, joissa on helppokäyttöiset käyttöliittymät, automatisoidut huoltotoiminnot ja verkkoyhteys saumattoman työnkulun integrointia varten. Sovellukset kattavat kaupalliset kyltit, mainosmateriaalit, pakkausprototyypit, dekoratiivipaneelit, personoidut lahjatuotteet, teollinen merkintä, arkkitehtoniset elementit ja räätälöidyt valmistuskomponentit. Tuotantonopeudet vaihtelevat huomattavasti laatuasettelujen ja alustan monimutkaisuuden mukaan, ja nykyaikaiset järjestelmät voivat saavuttaa jopa 50 neliömetriä tunnissa luonnoslaadussa samalla säilyttäen erinomaisen yksityiskohtaisuuden tuotantonopeuksissa. Ympäristötekijät vaikuttavat UV-digitaalitulostimien hintaan, koska nämä järjestelmät kuluttavat yleensä vähemmän energiaa kuin perinteiset painomenetelmät ja poistavat liuottimipohjaisten vaihtoehtojen aiheuttamat haihtuvat orgaaniset yhdisteet.