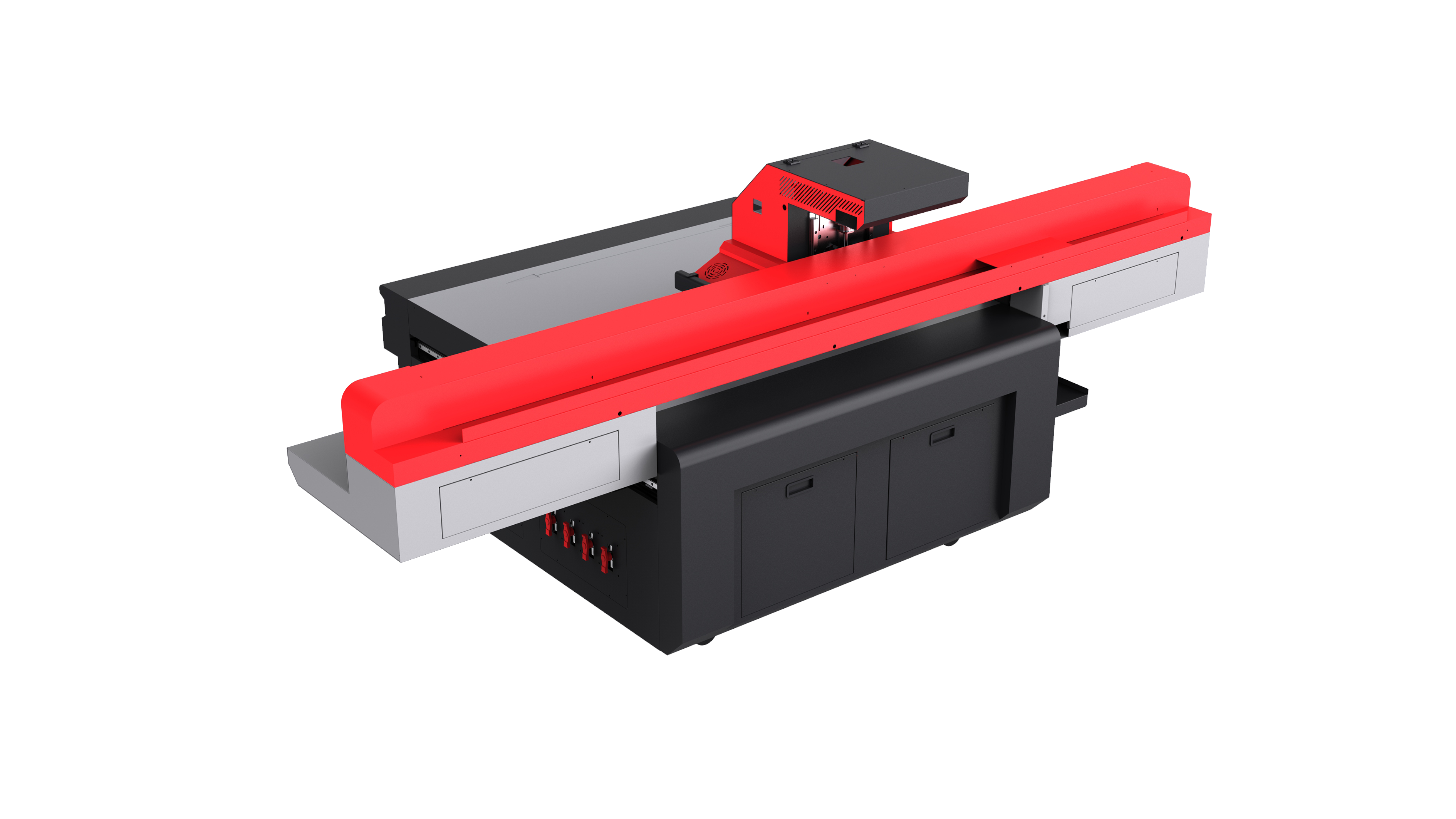

Kiváló anyagkompatibilitás korlátlan alkalmazási lehetőségekhez

A UV síknyomtatók rendkívüli anyagkompatibilitása megszünteti a hagyományos korlátokat, és korlátlan kreatív és kereskedelmi lehetőségeket nyit meg. Ezek a sokoldalú gépek közvetlenül nyomtathatnak merev hordozókra, akár vékony papírtól kezdve néhány hüvelyk vastagságú tárgyakig, széleskörű felületeken, beleértve fát, üveget, fémeket, műanyagokat, bőrt, textíliákat, köveket, kerámiaanyagokat és kompozit anyagokat is. Ez a képesség kiküszöböli az egyéb nyomtatási technológiákhoz szükséges költséges előkezelési eljárásokat és hordozó-előkészítési lépéseket. A vákuumos rögzítőrendszer biztosítja az irreguláris vagy rugalmas anyagok megtartását a nyomtatás során, így pontos regisztrációt és konzisztens minőséget garantál az egész nyomtatási területen. A változó vastagságú anyagok kezelése lehetővé teszi dimenzionált tárgyak, például promóciós termékek, ipari alkatrészek, építészeti elemek és művészeti darabok nyomtatását, amelyeket hengeres nyomtatókkal lehetetlen lenne elkészíteni. A fehér tinta funkció forradalmasítja a sötét vagy átlátszó hordozókra való nyomtatást, lehetővé téve élénk színvisszaadást olyan anyagokon, mint a fekete akril, színes üveg vagy áttetsző műanyagok, ahol a hagyományos CMYK tinták láthatatlanok lennének. Ez a funkció jövedelmező piacokat nyit meg, beleértve a háttérfényezett táblákat, ablakgrafikákat és prémium csomagolási alkalmazásokat. A speciális tinták, mint például fémesek, fluoreszkálók és textúra-hozzáadók tovább bővítik a kreatív lehetőségeket, miközben megőrzik az UV-technológia azonnali polimerizálódásának előnyeit. A nyomtatók rugalmas és merev anyagokat egyaránt kezelnek mechanikai beállítások nélkül, így leegyszerűsítik a különböző feladattípusok közötti átállást. Az előkészítési igények minimálisak, csökkentve a munkaerőköltségeket és a gyártási időt, miközben professzionális minőséget biztosítanak. A technológia alkalmas előre befejezett anyagok, például festett fémek vagy textúrázott felületek feldolgozására is, amelyeket a hőt vagy nyomást igénylő hagyományos nyomtatási eljárások megrongálnának. A dimenziós nyomtatási képesség domború hatásokat és tapintható felületeket eredményez, amelyek növelik a vizuális vonzerőt és az észlelt értéket. Az anyagok sokfélesége támogatja a különféle iparágakat, beleértve az építészeti táblarendszereket, az ipari azonosítást, a promóciós termékeket, a finom művészetek reprodukálását, a csomagolási prototípusokat és speciális gyártási alkalmazásokat, így az UV síknyomtatók értékes befektetéssé válnak azok számára, akik szolgáltatásaik diverszifikálására és új piaci lehetőségek megragadására törekednek.