Compatibilità Versatile per Multipli Applicazioni

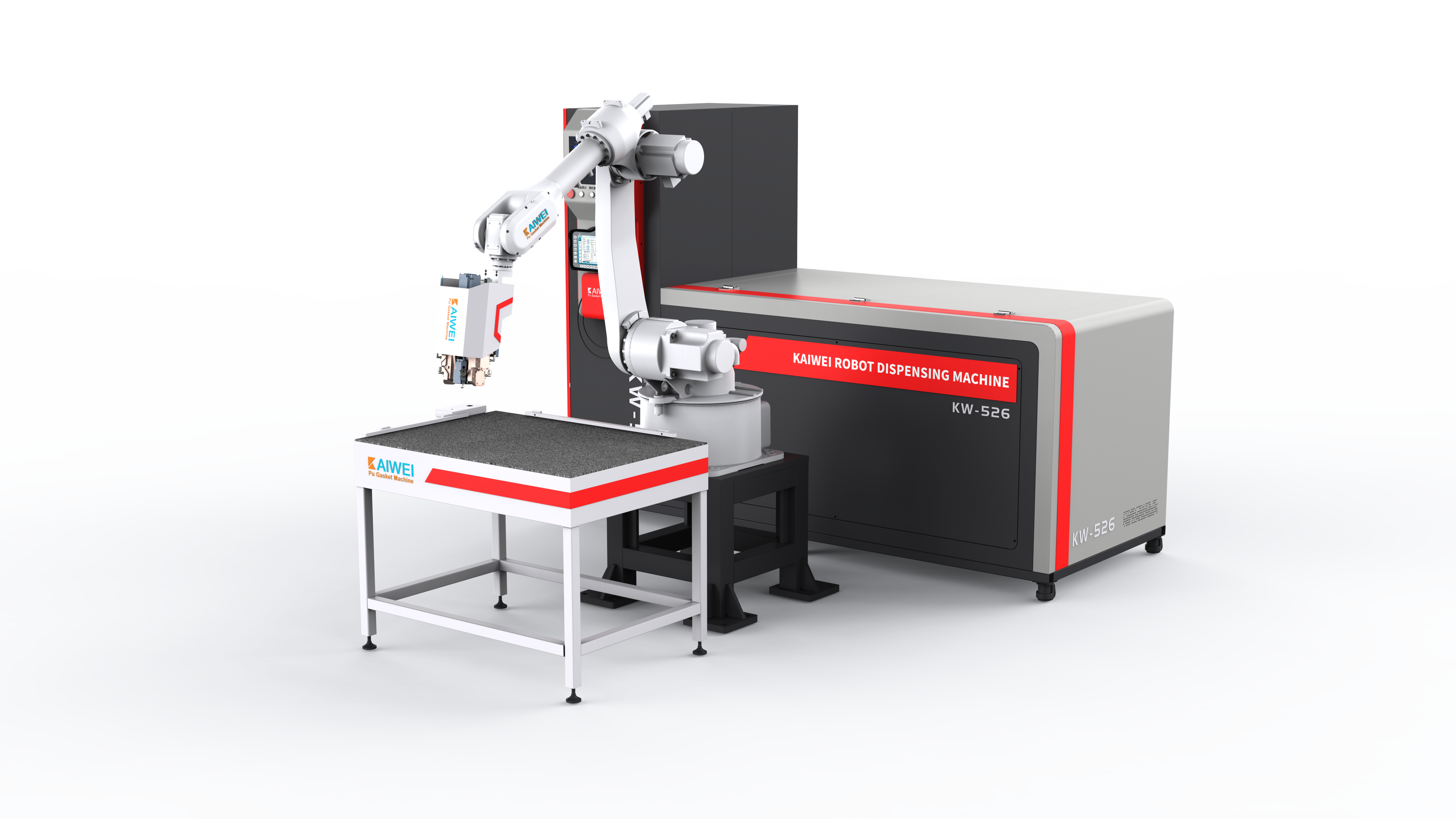

La nuova macchina per la dispensazione di poliuretano dimostra un'eccezionale versatilità grazie alla compatibilità multi-applicativa, adattandosi a diverse formulazioni di poliuretano e a requisiti industriali in numerosi settori. Questa adattabilità deriva dall'architettura modulare della macchina, che consente una rapida riconfigurazione per diversi materiali, viscosità e metodi di applicazione senza tempi di fermo prolungati o modifiche all'equipaggiamento. Il sistema gestisce con pari precisione e affidabilità sia adesivi a bassa viscosità sia schiume strutturali ad alta densità. Diverse opzioni di teste di dispensazione permettono ai produttori di passare da schemi di spruzzo ad applicazioni a cordone fino alla dispensazione precisa di punti, in base alle specifiche esigenze del prodotto. I sistemi di controllo termico della macchina si adattano a materiali con diverse sensibilità termiche, mantenendo condizioni ottimali di lavorazione durante tutto il ciclo di applicazione. La compatibilità chimica comprende sistemi a base di poliuretano, tra cui polioli, isocianati, catalizzatori e additivi specializzati utilizzati in formulazioni avanzate. La nuova macchina per la dispensazione di poliuretano supporta sia sistemi reattivi che non reattivi grazie a percorsi fluidi isolati che prevengono contaminazioni incrociate tra materiali diversi. I sistemi di regolazione della pressione si adattano automaticamente per gestire materiali che vanno da rivestimenti sottili a composti strutturali spessi, senza compromettere la qualità dell'applicazione. La flessibilità della macchina si estende alla compatibilità con i substrati, consentendo l'incollaggio efficace del poliuretano su metalli, plastiche, compositi e materiali porosi attraverso parametri di applicazione ottimizzati. Le capacità di integrazione nella linea di produzione permettono al sistema di adattarsi a diverse configurazioni produttive, inclusi processi continui su nastro trasportatore e operazioni di lavorazione per lotti. I sistemi di controllo versatili consentono programmazioni personalizzate per schemi di applicazione unici e geometrie complesse, difficilmente realizzabili o impossibili da ottenere manualmente. Questa compatibilità multi-applicativa riduce la necessità di investimenti in attrezzature, poiché i produttori possono utilizzare un singolo sistema per più linee di prodotto anziché acquistare apparecchiature specializzate per ogni applicazione. L'adattabilità della nuova macchina per la dispensazione di poliuretano garantisce un valore duraturo nel tempo, consentendo alle aziende di evolversi ed espandere le proprie offerte di prodotto senza dover sostituire completamente l'equipaggiamento.