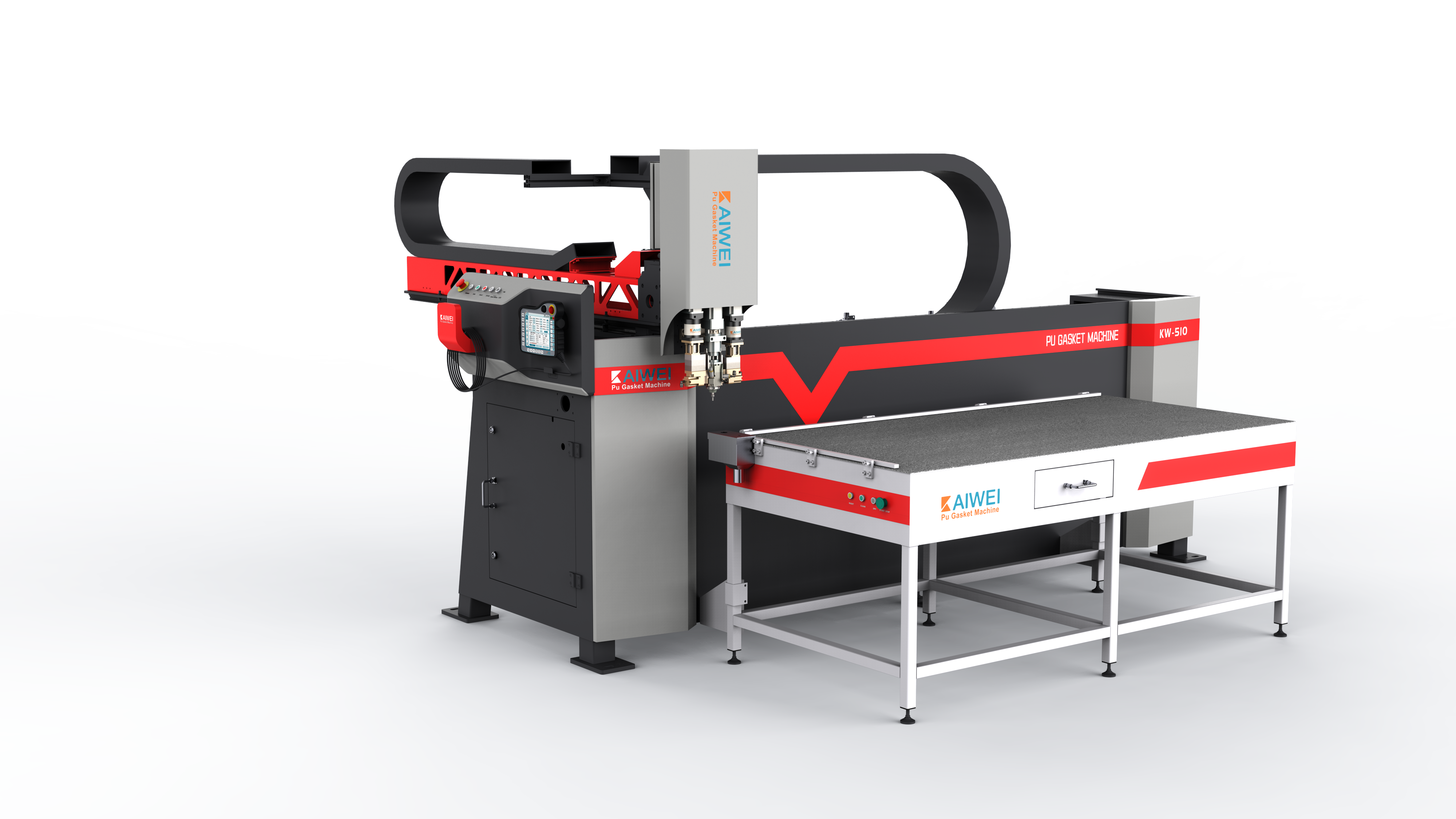

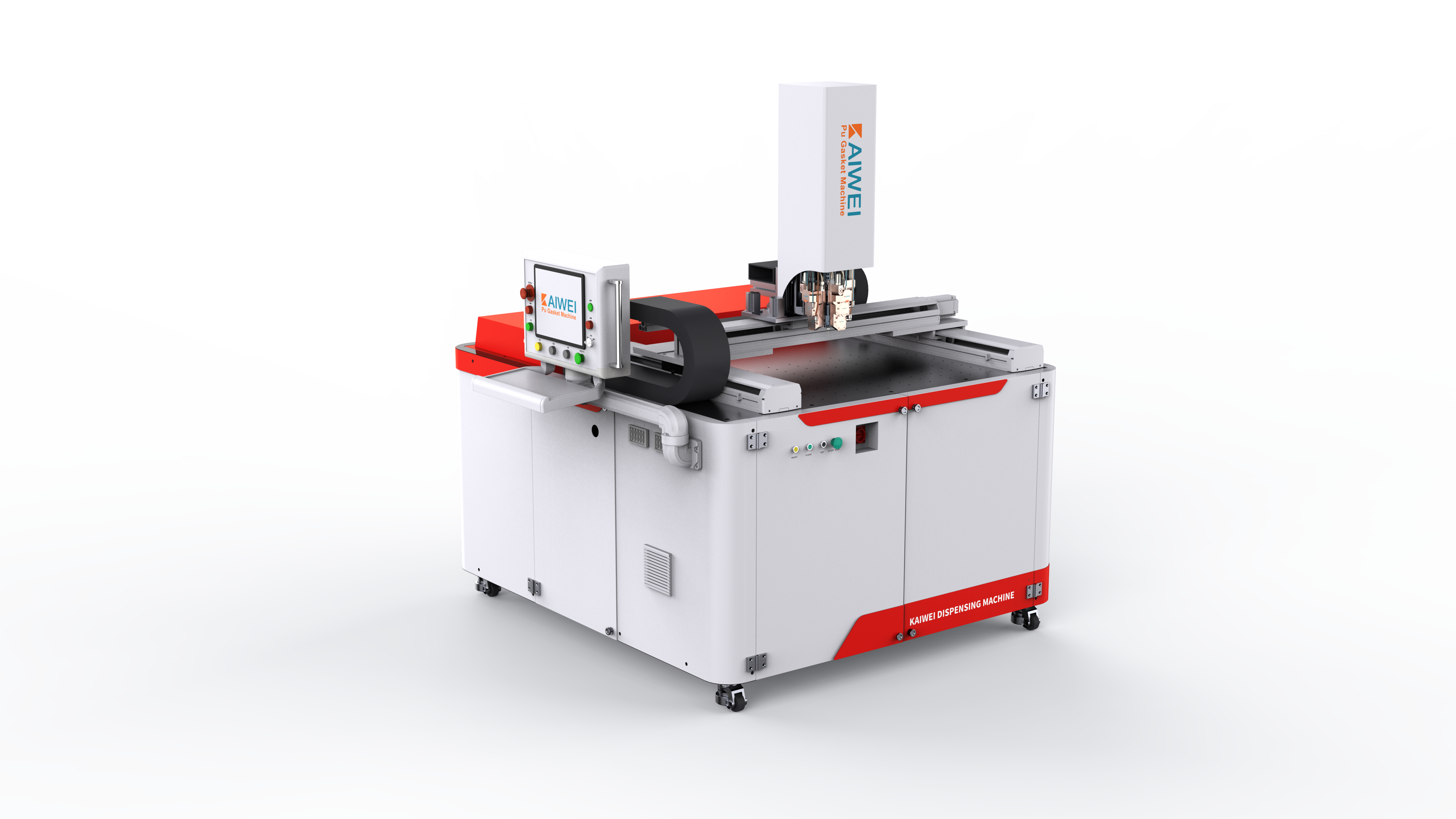

מכונה לחיתוך פה Foam בלחץ נמוך

מכונת הזרקה בלחץ נמוך מייצגת התקדמות מהפכנית בטכנולוגיה של ייצור קצף פוליאורטן, שתוכננה כדי לעמוד בדרישות התובעניות של תהליכי ייצור מודרניים. ציוד מתוחכם זה פועל ברמות לחץ מופחתות משמעותית בהשוואה למערכות לחץ גבוה מסורתיות, ופועלת בדרך כלל בין 50 ל-200 בר, מה שהופך אותה לפתרון אידיאלי למגוון יישומים תעשייתיים. הפונקציונליות העיקרית של המכונה מתמקדת במיקס ובשחיקה מדויקים של רכיבי פוליאורטן לשם ייצור מוצרים איכותיים של קצף עם עקביות ואמינות יוצאות דופן. מערכת המדידה המתקדמת שלה מבטיחה בקרת יחס מדויק בין רכיבי פוליאול ואייזוסיאנית, בעוד שמערכת החימום המשולבת שומרת על תנאי טמפרטורה אופטימליים לאורך כל מחזור הייצור. מכונת הזרקה בלחץ נמוך מצוידת בבקרות דיגיטליות מתקדמות המאפשרות לאופרטורים לנטר ולכוונן פרמטרים בזמן אמת, להבטחת איכות יציאה עקבית ולצמצום פסולת. הציוד כולל ראשוני ערבוב מיוחדים שתוכננו לפעול בלחץ נמוך, מה שמפחית בצורה משמעותית את ההתבלה ודרישות התפעול, וכן מאריך את משך החיים התפעולי. דגמים מודרניים כוללים מערכות ניקוי אוטומטיות שמשפרות את הליכי התפעול ומפחיתות את זמני העמידה בין מחזורי ייצור. העיצוב המודולרי של המכונה מאפשר התאמה קלה ליישומים ספציפיים, בין אם לייצור קצף גמיש לריהוט, קצף קשיח לבידוד או מוצרים מיוחדים של קצף לתעשיית הרכב והבנייה. נושאים סביבתיים טופלו באמצעות שימוש יעיל בחומרים ופליטות מופחתות בהשוואה למערכות ישנות של לחץ גבוה. מכונת הזרקה בלחץ נמוך תומכת בצפיפויות שונות של קצף ובהרכביהם, מה שהופך אותה לגמישה מספיק כדי להתמודד עם דרישות לקוחות מגוונות. הרגל הקטנה שלה מקסימה את ניצול שטח הרצפה תוך שמירה על יכולות ייצור מלאות. תכונות בטיחות כוללות מערכות עצירה חירום, ניטור לחץ וכיסויים מגנים כדי להבטיח הגנה על המפעילים במהלך הפעלה.