Ерекше субстрат көпшілдігі мен материалдарға үйлесімділік

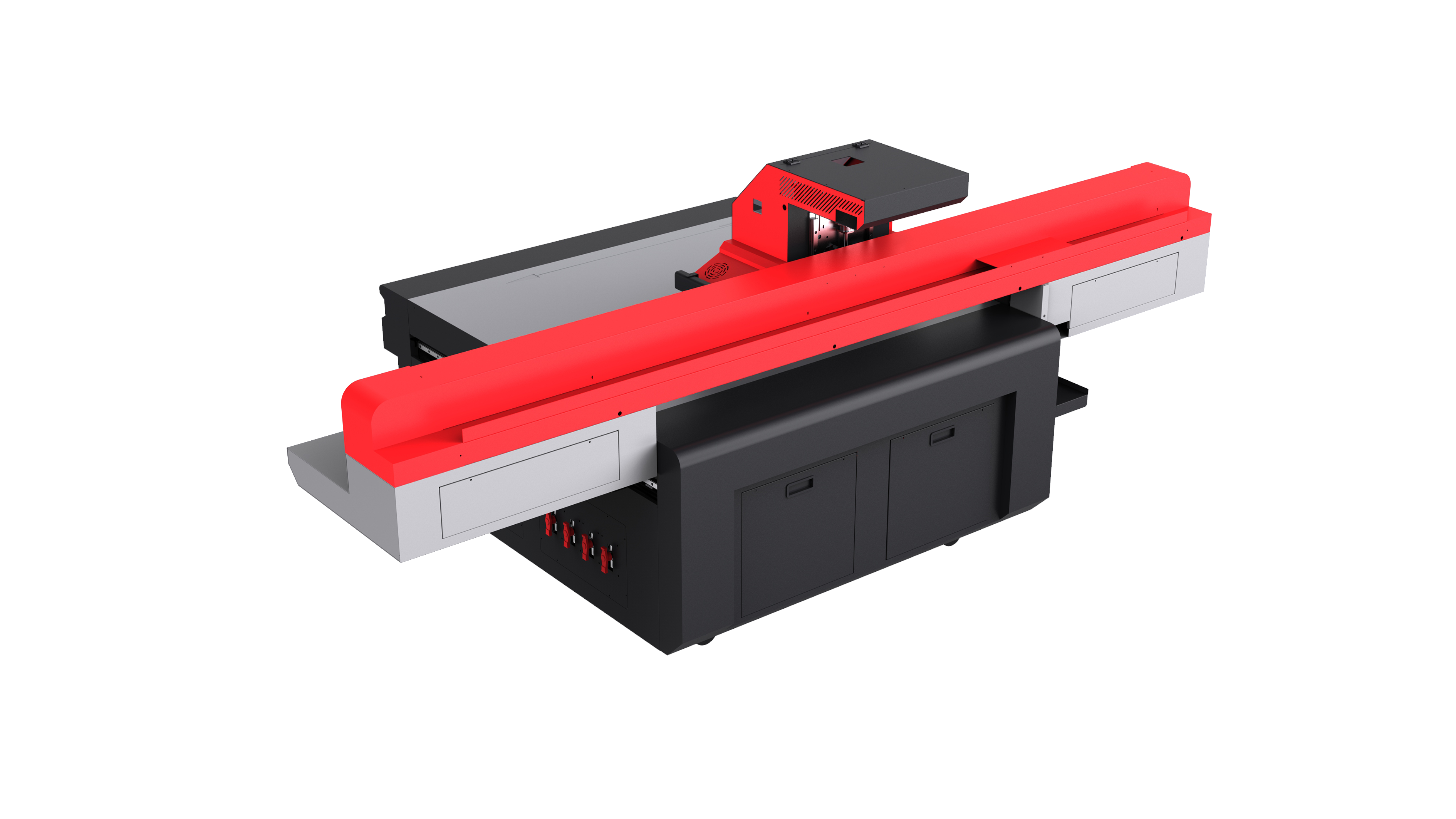

Ең арзан УК жазық станокты принтер әртүрлі материалдар мен негіздерге тікелей басып шығару қабілетінде ерекшеленеді, пайдаланушыларға бірнеше салада және қолданыста шексіз шығармашылық пен коммерциялық мүмкіндіктерді ашатын тұрақты көптеген қолданбаларды ұсынады. Бұл ерекше негізге сәйкестік УК-пен қатаятын сиялардың өзіндік қасиеттерінен және әртүрлі қалыңдықтағы, дәлдіктегі және құрамдағы материалдарды орнатуға мүмкіндік беретін жазық станок конструкциясынан туындайды, сонымен қатар арнайы дайындық немесе аралық тасымалдау процестерін талап етпейді. Пайдаланушылар тікелей ағаш, металл, пластик, шыны, керамикалық плитка, тас, композитті материалдар сияқты қатты материалдарға, сондай-ақ тері, мата, холст және әртүрлі жасанды материалдар сияқты иілгіш негіздерге де басып шығара алады, бұл кәдімгі басып шығару технологияларымен байланысты шектеулерді жояды. Үш өлшемді заттар мен тегіс емес беттерді өңдеу мүмкіндігі шығармашылық мүмкіндіктерді экспоненциалды түрде кеңейтеді және компанияларға телефон қаптамалары, таратылатын өнімдер, ғимарат элементтері және дәстүрлі жазық басып шығару әдістерімен жасау мүмкін болмайтын әдемі орындар сияқты заттарға дербес басып шығару қызметін ұсынуға мүмкіндік береді. Бұл көпжақтылық бизнеске қосымша арнайы жабдықтар сатып алу немесе жұмысты басқа қызмет көрсетушілерге тапсыру қажетсізінше әртүрлі сауда секторларынан әртүрлі жобаларды қабылдауға мүмкіндік беру арқылы тікелей табыс мүмкіндіктерін арттырады. Ең арзан УК жазық станокты принтер әртүрлі материалдар бойынша басып шығарудың тұрақты сапасын сақтайды, себебі ол автоматты түрде сияның түсуін және қату параметрлерін реттейді, нәтижесінде негіздің сипаттамаларына қарамастан тиімді жабысуын және түстердің дәлме-дәл берілуін қамтамасыз етеді. Бұл икемділік архитекторлардан ғимарат материалдарының үлгілерін талап ететін, әртістерден әртүрлі материалдардан тұратын инсталляциялар жасауға дейінгі, өндірушілерден прототиптерді белгілеу мен анықтау қажеттілігіне дейінгі әртүрлі тұтынушыларға қызмет көрсететін бизнес үшін ерекше маңызды болып табылады. Тікелей басып шығару мүмкіндігі винил кесу, жылулық трансфер немесе желім қолдану сияқты аралық кезеңдерді жояды, өндіріс уақытын, материалдарға кететін шығындарды және сапаға қатысты мүмкін болатын мәселелерді азайтады және дайын өнімдер бойынша пайданы арттырады.