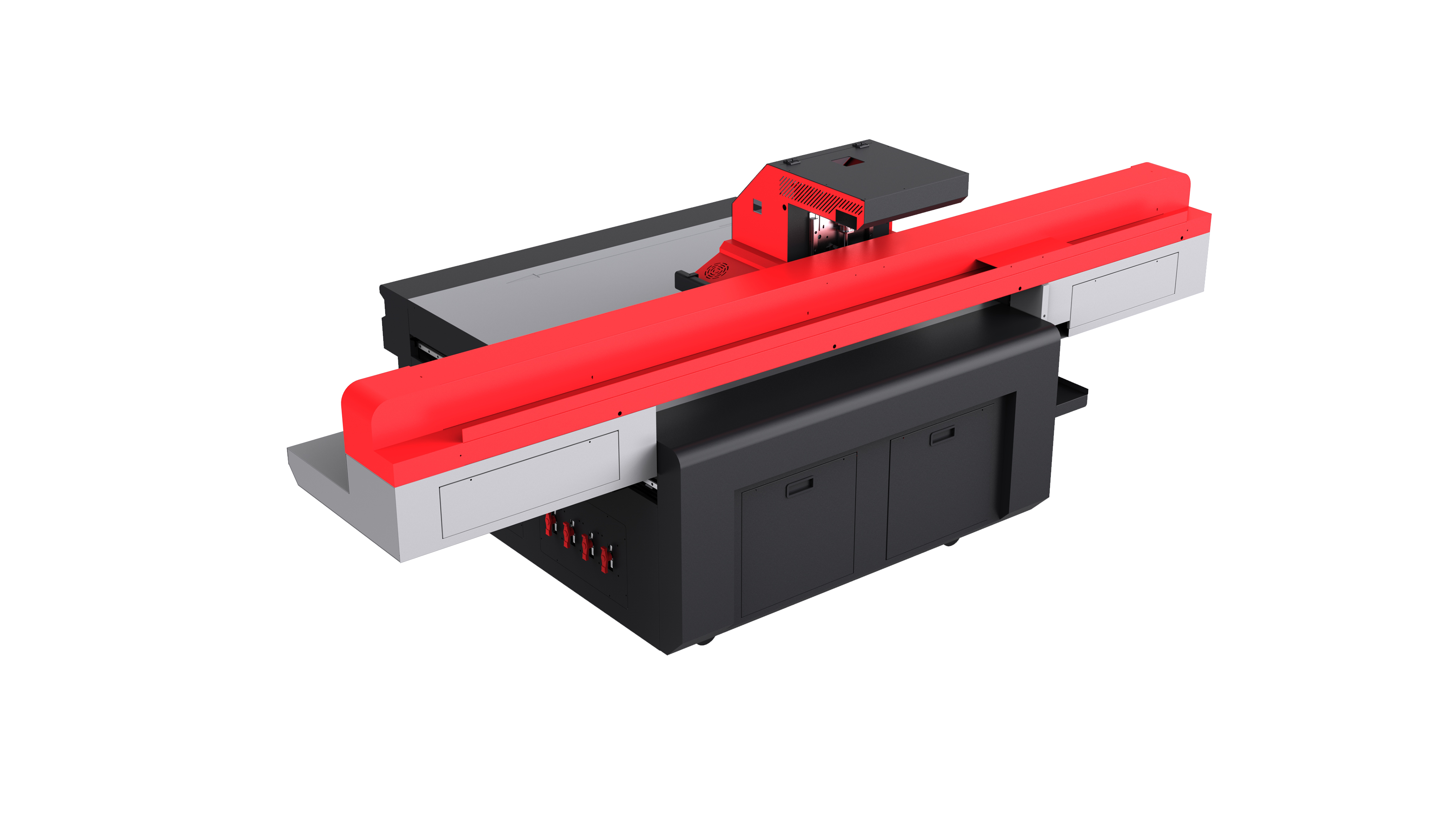

ຄວາມສາມາດໃນການໃຊ້ວັດສະດຸພື້ນຖານແລະຄວາມເຂົ້າກັນໄດ້ຂອງວັດສະດຸທີ່ດີເລີດ

ຄວາມສາມາດໃນການນໍາໃຊ້ວັດສະດຸພື້ນຖານທີ່ຫຼາກຫຼາຍຢ່າງຫນ້າປະທັບໃຈຂອງເຕັກໂນໂລຊີການພິມດິຈິຕອລ UV ແມ່ນໜຶ່ງໃນຂໍ້ໄດ້ປຽບທີ່ສໍາຄັນທີ່ສຸດ, ຊ່ວຍໃຫ້ທຸລະກິດສາມາດຂະຫຍາຍການບໍລິການ ແລະ ຄວາມສາມາດໃນການສ້າງສັນຂອງພວກເຂົາໄປສູ່ວັດສະດຸ ແລະ ການນໍາໃຊ້ທີ່ແຕກຕ່າງກັນຢ່າງກວ້າງຂວາງ. ລະບົບການພິມດິຈິຕອລ UV ສາມາດພິມໂດຍກົງໄປເທິງວັດສະດຸແຂງ ເຊັ່ນ: ລວມເຖິງໂລຫະຕ່າງໆ ເຊັ່ນ: ໂລຫະອັລຢູມິນຽມ, ໂລຫະເຫຼັກ, ແລະ ໂລຫະແທ້, ຜະລິດຕະພັນໄມ້ຕັ້ງແຕ່ໄມ້ກະດານອັດລົງຮອດໄມ້ແຂງປະເພດແປກ, ພື້ນຜິວແກ້ວ ລວມເຖິງແກ້ວປ້ອງກັນ ແລະ ແກ້ວພິເສດ, ແຜ່ນເຊີຣາມິກ ແລະ ສິນຄ້າໂຄສະນາ, ແລະ ວັດສະດຸຢາງພລາສຕິກຕ່າງໆ ຕັ້ງແຕ່ acrylic ຫາ polycarbonate. ຄວາມສາມາດນີ້ຍັງຂະຫຍາຍໄປສູ່ວັດສະດຸຍືດຍຸ່ນ ລວມເຖິງຟິມຢາງ vinyl, ເສັ້ນໃຍຜ້າ, ເຈ້ຍສັງເຄາະ, ແລະ ຟິມພິເສດທີ່ອອກແບບມາສໍາລັບການນໍາໃຊ້ໂດຍສະເພາະ ເຊັ່ນ: ກາຟິກປ່ອງຢ້ຽມ, ກາຟິກພື້ນ, ແລະ ປ້າຍນອກອາຄານ. ເຄມີສາດຂອງນໍ້າໝຶກ UV ສາມາດຜູກຕິດກັບພື້ນຜິວວັດສະດຸທີ່ແຕກຕ່າງກັນໄດ້ຢ່າງມີປະສິດທິພາບ ໂດຍບໍ່ຈໍາເປັນຕ້ອງໃຊ້ primer, ການປິ່ນປົວລ່ວງໜ້າ, ຫຼື ຊັ້ນຄຸມພິເສດໃນຫຼາຍກໍລະນີ, ຊ່ວຍງ່າຍຂຶ້ນໃນຂະບວນການຜະລິດ ແລະ ຫຼຸດຜ່ອນຕົ້ນທຶນວັດສະດຸ ໃນຂະນະທີ່ຮັກສາຄວາມຕິດດີ ແລະ ຄວາມທົນທານໄວ້. ຄວາມສາມາດໃນການພິມໃສ່ວັດສະດຸທີ່ມີສີເຂັ້ມ ແລະ ວັດສະດຸທີ່ແຈ້ງໂດຍໃຊ້ນໍ້າໝຶກສີຂາວເປັນພື້ນຖານ ຫຼື ສີເນັ້ນໜັກ ເປີດໂອກາດໃໝ່ໆໃຫ້ແກ່ນັກອອກແບບ ແລະ ເຮັດໃຫ້ສາມາດຜະລິດຜົນກະທົບທີ່ເປັນເອກະລັກ ເຊັ່ນ: ການພິມກົງກັນຂ້າມກັບວັດສະດຸແຈ້ງ, ຮູບແບບຊັ້ນໆທີ່ມີຄວາມລະອຽດ, ແລະ ກາຟິກທີ່ມີຄວາມຕັດກັນສູງໃສ່ພື້ນຖານສີເຂັ້ມ. ເຕັກໂນໂລຊີການພິມດິຈິຕອລ UV ສາມາດຮັບວັດສະດຸທີ່ມີຄວາມໜາແຕກຕ່າງກັນໄດ້, ຈາກຟິມບາງໆທີ່ມີຄວາມໜາເຄິ່ງໜຶ່ງມິນຕີເມັດ ຫາແຜ່ນແຂງທີ່ໜາຫຼາຍນິ້ວ, ໃຫ້ຄວາມຍືດຍຸ່ນສໍາລັບການນໍາໃຊ້ຜະລິດຕະພັນທີ່ແຕກຕ່າງກັນ ແລະ ຄວາມຕ້ອງການການຜະລິດຕາມຄວາມຕ້ອງການ. ຄຸນນະພາບການພິມທີ່ສອດຄ່ອງກັນໃນທຸກປະເພດຂອງວັດສະດຸພື້ນຖານ ຮັບປະກັນວ່າທຸລະກິດສາມາດຮັກສາມາດຕະຖານຄຸນນະພາບຂອງພວກເຂົາໄດ້ ເຖິງວ່າຈະເລືອກໃຊ້ວັດສະດຸໃດກໍຕາມ, ເຮັດໃຫ້ພວກເຂົາສາມາດຮັບປະກັນຜົນໄດ້ຮັບໃຫ້ແກ່ລູກຄ້າຂອງພວກເຂົາໄດ້ຢ່າງໝັ້ນໃຈ. ຄວາມເຂົ້າກັນໄດ້ກັບວັດສະດຸນີ້ຍັງຂະຫຍາຍໄປສູ່ພື້ນຜິວທີ່ມີເນື້ອຜິວ ເຮັດໃຫ້ສາມາດພິມໃສ່ວັດສະດຸທີ່ມີລາຍນູນ, ພື້ນຜິວແບບຖູ, ແລະ ການປິ່ນປົວພື້ນຜິວອື່ນໆທີ່ຈະເປັນໄປໄດ້ຍາກ ຫຼື ບໍ່ສາມາດເຮັດໄດ້ດ້ວຍວິທີການພິມແບບດັ້ງເດີມ. ເຕັກໂນໂລຊີນີ້ສະໜັບສະໜູນການພິມໃສ່ວັດສະດຸທີ່ອ່ອນໄຫວຕໍ່ຄວາມຮ້ອນ ທີ່ບໍ່ສາມາດຮັບຄວາມຮ້ອນສູງທີ່ຈໍາເປັນສໍາລັບຂະບວນການພິມທີ່ໃຊ້ຄວາມຮ້ອນໄດ້, ຂະຫຍາຍການນໍາໃຊ້ໄປສູ່ຢາງພລາສຕິກທີ່ອ່ອນໄຫວຕໍ່ຄວາມຮ້ອນ, ເສັ້ນໃຍສັງເຄາະ, ແລະ ຟິມພິເສດທີ່ອອກແບບມາສໍາລັບການນໍາໃຊ້ອຸດສາຫະກໍາໂດຍສະເພາະ.