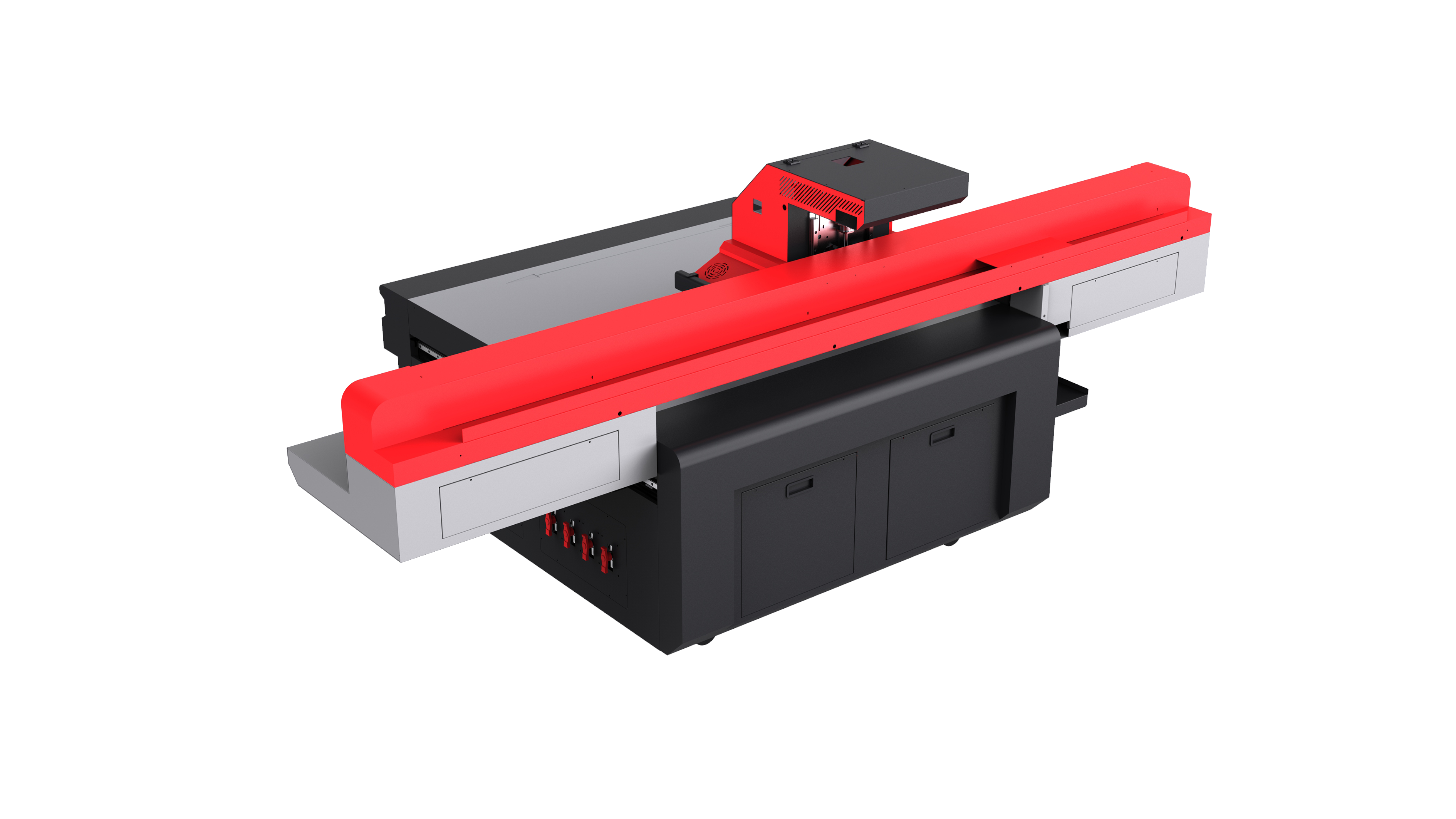

kleine formaat uv flatbed printer

Een small-format UV-vlakbedprinter vormt een revolutionaire vooruitgang in digitale printtechnologie en biedt bedrijven en creatieve professionals een efficiënte oplossing voor het produceren van hoogwaardige afdrukken op diverse materialen. Dit compacte printsysteem combineert ultraviolette LED-uithardingstechnologie met precisie-inkjetprinten om uitzonderlijke resultaten te leveren op uiteenlopende ondergronden. De small-format UV-vlakbedprinter werkt door UV-hardinke op de materialen te spuiten, gevolgd door directe uitharding via LED-UV-lampen, waardoor duurzame en levendige afdrukken ontstaan die bestand zijn tegen vervagen, krassen en weersinvloeden. De belangrijkste functies zijn direct printen op stijve materialen tot enkele centimeters dikte, wit inkt printen op donkere ondergronden en variabele dataproductiemogelijkheden. Deze printers kunnen materialen verwerken variërend van traditionele media zoals papier en karton tot ongebruikelijke oppervlakken zoals hout, metaal, glas, keramiek, kunststoffen en textiel. De technologische kenmerken omvatten geavanceerde printkoppen met variabele druppeltechnologie, wat zorgt voor vloeiende overgangen en scherpe tekstweergave. Kleurbeheersystemen zorgen voor nauwkeurige kleurafstemming en consistentie tussen oplagen. Het UV-LED-uithardingssysteem elimineert de droogtijd, waardoor geprint materiaal direct kan worden verwerkt en afgewerkt. Veel modellen beschikken over automatische mediadetectie en automatische hoogteaanpassing, wat het printproces vereenvoudigt. Toepassingen zijn wijdverspreid in talloze sectoren, waaronder bordenproductie, productie van promotionele artikelen, verpakkingsprototyping, architectonische visualisatie, reproductie van beeldende kunst en het maken van op maat gemaakte geschenken. Kleinere bedrijven profiteren van de mogelijkheid om gepersonaliseerde producten aan te bieden, terwijl grotere organisaties de efficiëntie en veelzijdigheid op prijs stellen. De technologie maakt het mogelijk om te printen op driedimensionale objecten, wat kansen biedt voor het personaliseren van telefoonhoesjes, promotionele items, trofeeën en industriële componenten. Onderwijsinstellingen gebruiken deze printers voor prototyping en creatieve projecten, terwijl advertentiebureaus erop vertrouwen voor snelle oplevering van promotiemateriaal en presentatievoorbeelden.