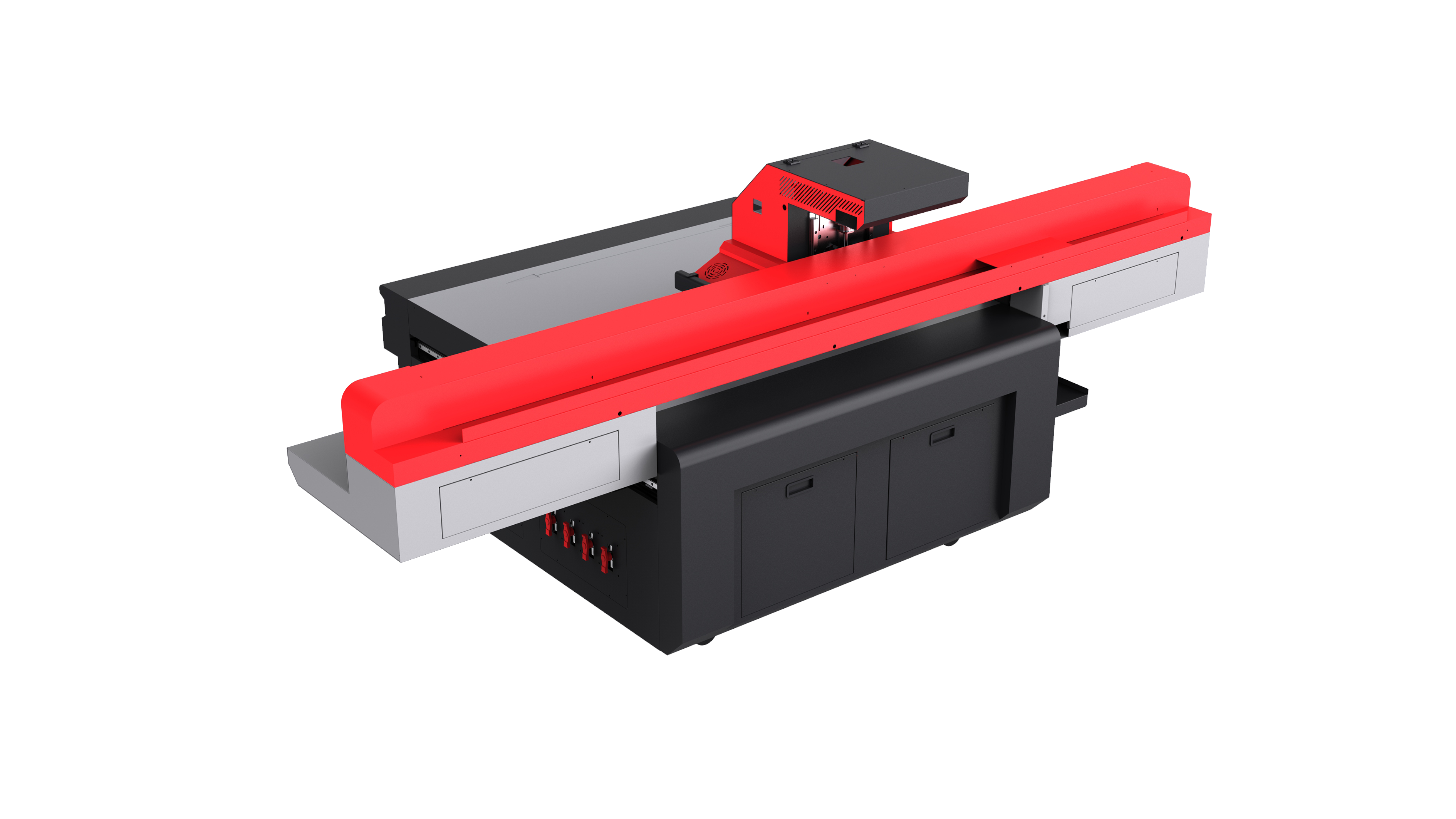

a4 uv flatbed printer

Drukarka płaskostronna a4 uv to rewolucyjny postęp w technologii druku cyfrowego, zaprojektowana specjalnie do obsługi wymagań drukowania w małym i średnim formacie z wyjątkową precyzją i uniwersalnością. To kompaktowe, ale potężne rozwiązanie drukujące wykorzystuje technologię utrwalania ultrafioletem, aby natychmiast wysuszyć i utrwalić specjalnie sformułowane farby UV, tworząc trwałe, barwne wydruki na szerokim zakresie materiałów. W przeciwieństwie do tradycyjnych metod druku, które wymagają długiego czasu schnięcia i określonych typów podłoży, drukarka a4 uv może drukować bezpośrednio na sztywnych materiałach, w tym drewnie, metalu, szkle, ceramice, plastiku, skórze oraz różnych materiałach kompozytowych o grubości dochodzącej do kilku centymetrów. Drukarka wykorzystuje zaawansowane głowice drukujące piezoelektryczne, które dostarczają mikroskopijne kropelki farby z zadziwiającą dokładnością, osiągając rozdzielczość do 1440 x 1440 dpi, zapewniając wyniki jakości fotograficznej. System utrwalania UV składa się z intensywnych lamp LED rozmieszczonych strategicznie tak, by utrwalać farbę natychmiast po jej nałożeniu, gwarantując odporność na zamazanie i umożliwiając natychmiastowe manipulowanie wydrukowanymi materiałami. Konstrukcja stołu płaskiego pozwala na umieszczenie obiektów o różnym kształcie i wielkości w granicach wymiarów formatu A4, co czyni ją idealną do prototypowania, personalizacji i krótkich serii produkcyjnych. Kluczowe cechy technologiczne obejmują technologię zmiennych kropli farby dla płynnych przejść barw, możliwość drukowania białą farbą na przezroczystych lub ciemnych materiałach oraz specjalistyczne oprogramowanie zarządzające profilami kolorów i optymalizacją druku. Drukarka integruje się bezproblemowo ze standardowym oprogramowaniem projektowym i aplikacjami RIP, obsługując wiele formatów plików, w tym PDF, TIFF, JPEG oraz grafikę wektorową. Zastosowania obejmują liczne branże, m.in. produkty promocyjne, reklamy, prototypy opakowań, spersonalizowane upominki, modele architektoniczne, obudowy elektroniczne, znakowanie urządzeń medycznych oraz reprodukcje artystyczne, co czyni drukarkę a4 uv nieocenionym narzędziem dla firm poszukujących niezawodnych rozwiązań drukarskich o profesjonalnej jakości.