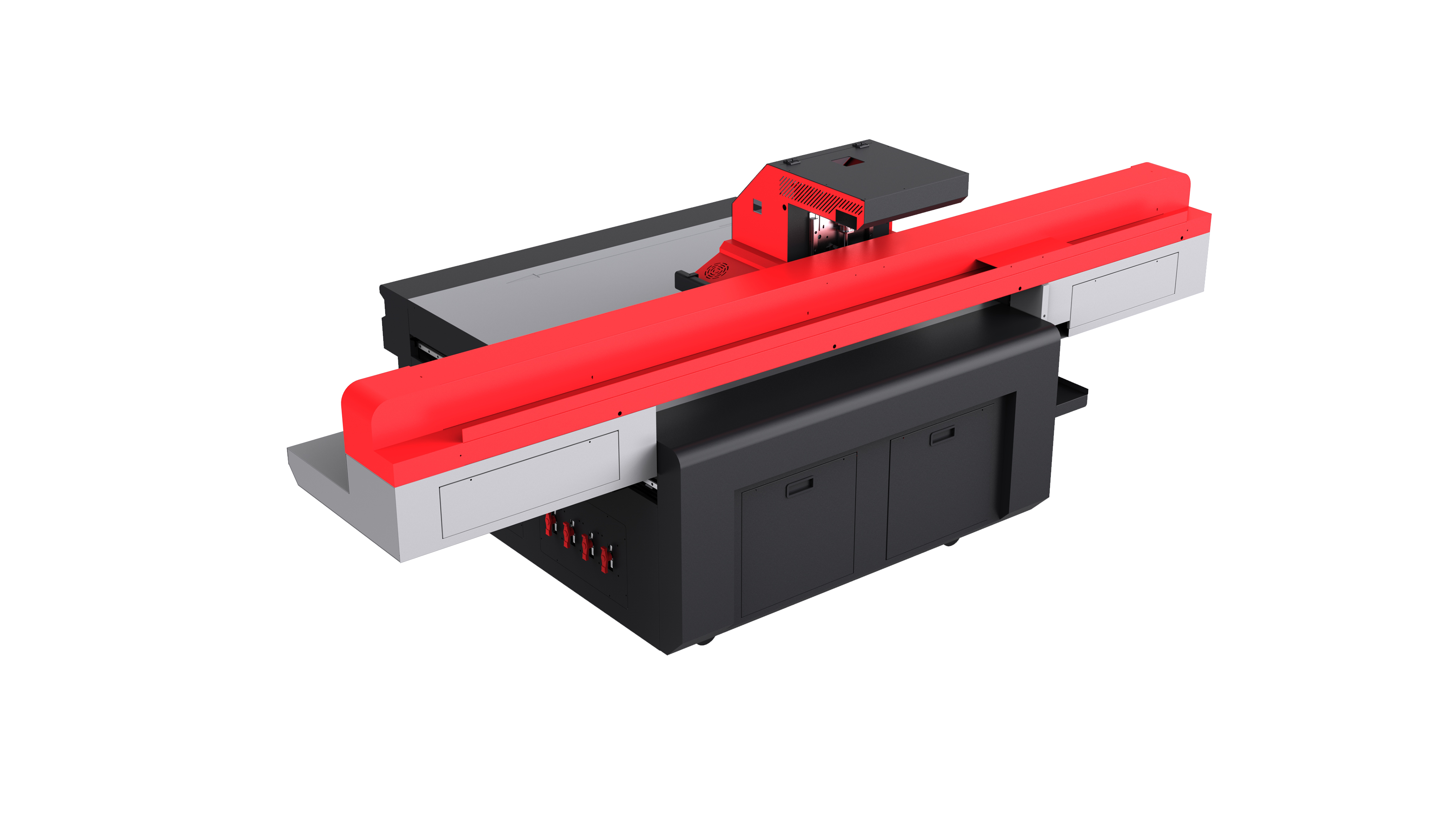

compre impressora digital UV

Um comprou impressora digital UV representa um investimento significativo em tecnologia moderna de impressão que revoluciona a forma como as empresas abordam aplicações comerciais e industriais de impressão. Essas máquinas sofisticadas utilizam tecnologia de cura por luz ultravioleta para secar e curar instantaneamente tintas UV especialmente formuladas, criando impressões vibrantes e duráveis em praticamente qualquer substrato. A funcionalidade principal de uma comprou impressora digital UV gira em torno de sua capacidade de depositar camadas precisas de tinta reativa ao UV sobre materiais que vão desde papel e papelão tradicionais até substratos rígidos como metal, vidro, madeira, plástico e cerâmica. O processo de impressão envolve a aplicação de tintas UV na superfície do substrato, seguida pela exposição imediata a lâmpadas UV LED de alta intensidade que curam instantaneamente a tinta, criando uma ligação química que resulta em durabilidade excepcional e resistência a arranhões. Impressoras digitais UV modernas possuem cabeças de impressão piezoelétricas avançadas que dispensam gotículas microscópicas com notável precisão, permitindo resoluções de até 1440 dpi ou superiores. A arquitetura tecnológica inclui sistemas sofisticados de gerenciamento de cor, tecnologia de gota variável e sistemas de cura multizona que garantem qualidade consistente em impressões de grande formato. Essas máquinas suportam configurações tanto rolo-a-rolo quanto plano, acomodando materiais de diferentes espessuras e dimensões. Os sistemas automatizados de manipulação de mídia reduzem a intervenção manual mantendo o registro preciso durante todo o processo de impressão. Mecanismos de controle de temperatura mantêm condições operacionais ideais para viscosidade constante da tinta e desempenho de cura. As aplicações abrangem indústrias diversas, incluindo produção de sinalização, embalagens, materiais promocionais, gráficos arquitetônicos, rotulagem industrial e impressão decorativa. A comprou impressora digital UV destaca-se em produções de pequenas tiragens, impressão personalizada e desenvolvimento de protótipos, onde métodos tradicionais de impressão se mostram economicamente inviáveis. A capacidade de usar tinta branca permite imprimir em substratos transparentes ou escuros, enquanto tintas especiais, incluindo formulações metálicas e texturizadas, ampliam significativamente as possibilidades criativas.