počasna strojna oprema za izdaljevanje pu

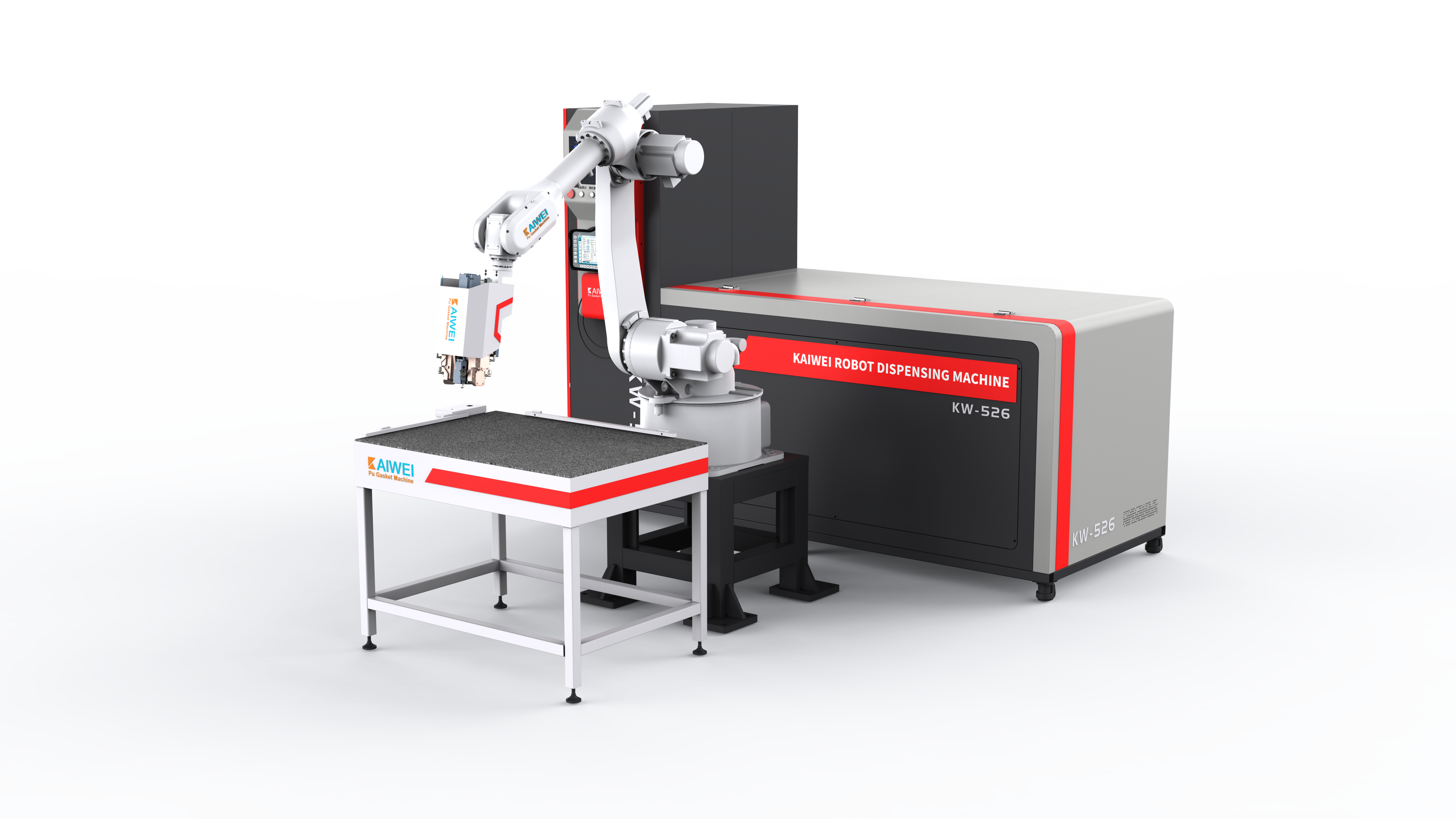

Jeftina naprava za odmerjanje poliuretana predstavlja revolucionarni napredek v industrijski avtomatizaciji, posebej zasnovano za ravnanje s poliuretanskimi materiali z izjemno natančnostjo in zanesljivostjo. Ta sofisticirana oprema predstavlja osnovo za številne proizvodne procese, pri čemer zagotavlja dosledne rezultate in hkrati ohranja učinkovitost stroškov, ki si jih lahko privoščijo tudi manjše podjetja. Naprava deluje prek naprednih dozirnih sistemov, ki zagotavljajo natančne razmere materialov, preprečujejo odpad in zagotavljajo kakovost izdelka pri vsakem ciklu uporabe. Sodobne enote jeftinih naprav za odmerjanje poliuretana vključujejo najnovejše nadzorne sisteme z digitalnimi vmesniki, ki omogočajo obratovalcem programiranje določenih parametrov za različne proizvodne zahteve. Te naprave odlično opravljajo pri mešanju dvokomponentnih poliuretanskih sistemov, samodejno združujejo smolo in katalizator v vnaprej določenih razmerjih, da ustvarijo enotne materiale za različne aplikacije. Tehnološka arhitektura vključuje natančne črpalke, segrete cevi in mešalne komore, ki ohranjajo optimalno temperaturo skozi celoten proces odmerjanja. Mehani zmi za nadzor temperature preprečujejo degradacijo materiala in zagotavljajo ustrezne kemične reakcije med uporabo. Jeftina naprava za odmerjanje poliuretana običajno vključuje nastavljive pretokovne hitrosti, kar omogoča proizvajalcem prilagoditi količine izdelave glede na specifične zahteve projekta. V konstrukcijo so vgrajeni varnostni protokoli, vključno s funkcijami za izklop v sili in zaščitnimi ohišji, ki zaščitijo obratovalce med delovanjem. Mnogi modeli vključujejo lastne možnosti čiščenja, ki zmanjšujejo zahteve za vzdrževanje in znatno podaljšujejo obratovalno življenjsko dobo. Vsestranskost teh naprav omogoča upravljanje z različnimi formulacijami poliuretana, od elastične pene do trdih strukturnih komponent, kar jih naredi neprecenljivimi v več industrijskih panogah. Zahtevi za namestitev so minimalni, saj so večina enot zasnovana za takojšnje vklopitev in delovanje, kar zmanjša zapletenost namestitve ter povezane stroške za podjetja, ki naložijo v tehnologijo avtomatizacije.