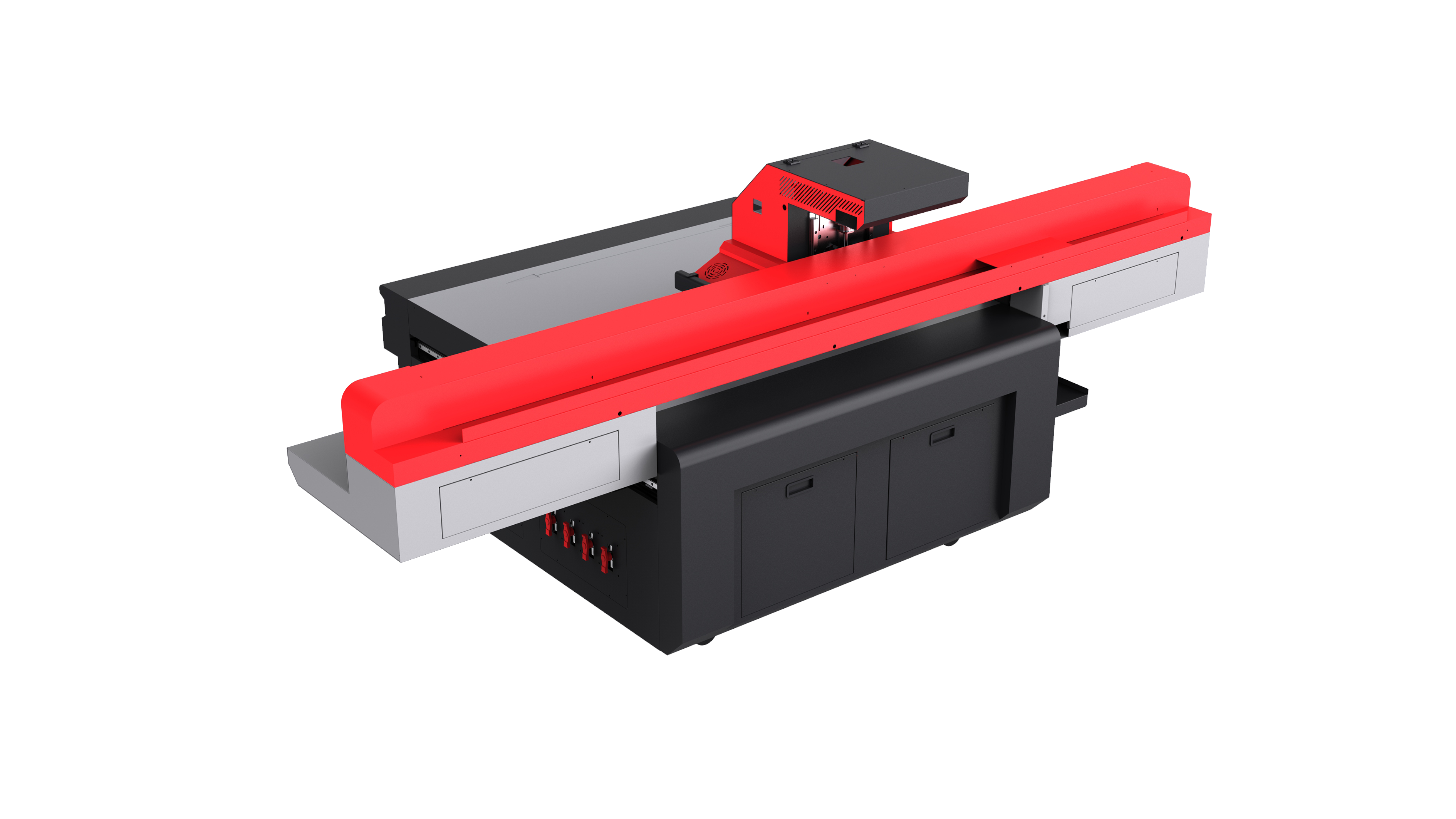

yakınlıktaki uv flatbed yazıcı

Yakınımdaki UV düz yüzeyli yazıcı, profesyonel seviyede baskı çözümleri arayan işletmeler için olağanüstü sonuçlar sunan son teknoloji dijital baskı teknolojisini temsil eder. Bu gelişmiş makineler, özel formüle edilmiş mürekkepleri anında sertleştirmek için ultraviyole ışık kullanarak neredeyse her malzeme yüzeyine canlı ve dayanıklı baskılar oluşturur. Yakınımdaki uv düz yüzeyli yazıcı, UV ile sertleşebilen mürekkeplerin altlık malzemelerinin üzerine damlatılıp yüksek yoğunluklu LED veya cıva buharlı lambalarla hemen katılaştırıldığı hassas bir süreçle çalışır. Bu yenilikçi yaklaşım, geleneksel kuruma süresini ortadan kaldırarak hızlı üretimi ve üstün baskı kalitesini mümkün kılar. Düz yüzeyli tasarım, ince filmlerden birkaç inç kalınlığa kadar olan sert panollere kadar çeşitli malzeme kalınlıklarını destekler. Gelişmiş baskı kafa teknolojisi, mikroskobik damla yerleştirilmesini sağlayarak fotografik kalitede çıktı elde etmek üzere maksimum 1440 dpi'ye varan çözünürlükler sunar. Modern uv düz yüzeyli yazıcı sistemleri, CMYK'nın yanı sıra beyaz ve şeffaf koruyucu kaplamalar gibi çoklu mürekkep konfigürasyonlarına sahiptir ve bu da yaratıcı imkanları genişletir. Çok yönlü altlık uyumluluğu, cam, metal, ahşap, plastik, seramik, deri ve tekstilleri kapsar ve bu yazıcıları çeşitli sektörler için vazgeçilmez hale getirir. Otomatik malzeme taşıma sistemleri iş akışı verimliliğini artırırken, gelişmiş renk yönetimi, baskı partileri boyunca tutarlı sonuçların alınmasını sağlar. Yakınımdaki uv düz yüzeyli yazıcı, farklı dosya biçimlerini destekleyen tasarım yazılımlarıyla sorunsuz şekilde entegre olur ve dijital dosyalardan doğrudan baskı yapılmasına olanak tanır. Çevresel faktörler, üreticileri düşük uçucu organik bileşik içeren çevre dostu UV mürekkepler geliştirmeye yöneltmiştir. Bu teknoloji, tabela üretimi, tanıtımsal materyaller, ambalaj prototipleri, mimari panolar, otomotiv grafikleri ve özel dekoratif ürünler dahil olmak üzere birçok uygulama alanında kullanılır. Uv düz yüzeyli yazıcı teknolojisine yapılan yatırım, işletmelere özelleştirilmiş baskı çözümleri için artan pazar taleplerini karşılamada dış kaynak kullanım maliyetlerinde azalma, daha hızlı teslim süreleri ve hizmet yelpazesinde genişleme gibi rekabet avantajları sağlar.