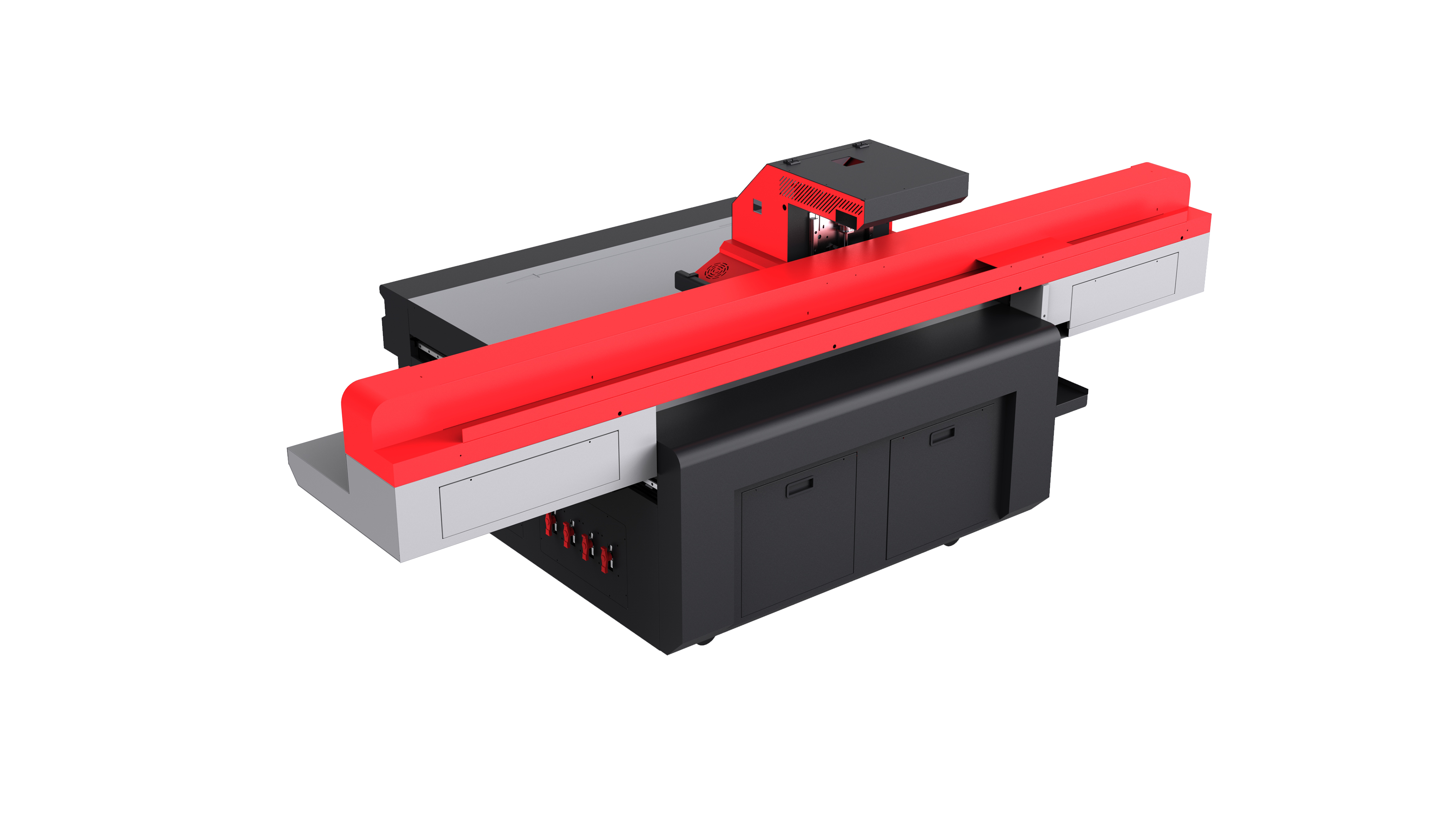

digital uyf bosma

Raqamli UV bosish zamonaviy bosmaxona texnologiyasidagi inqilobiy yutuq bo'lib, tashkilotlarning yuqori sifatli bosish ishlarini amalga oshirish usulini butunlay o'zgartirib yubordi. Ushbu yangi bosish usuli maxsus tayyorlangan UV eritmalarni darhol qattiq shtamplovchi ultrabinafsha nurlardan foydalanadi va xavfsiz, plastik, yog'och kabi turli xil materiallarga chidamli hamda rang-barang bosish imkonini beradi. Raqamli UV bosish jarayoni raqamli texnologiya aniq to'g'riligini va UV bilan qattiq shtamplovchi eritmalarning chidamliligini birlashtiradi, bu uni tijorat hamda sanoat sohasida ideal echim qiladi. Raqamli UV bosishning asosiy vazifalari — qog'oz, karton, shisha, metall, plastik va yog'och kabi materiallarga yuqori aniqlikdagi rasm, matn va grafikalar hosil qilishdan iborat. Texnologiya maxsus moddalarga UV-chuvrak eritmalar solinib, darhol ultrabinafsha nurlar ostida qattiq shtamplovchi murakkab tizim orqali amalga oshiriladi, natijada eritma polimerlanadi va sirtga doimiy ravishda birikadi. Raqamli UV bosishning eng muhim texnik jihatlidan biri — quritish vaqtiga ehtiyoj bo'lmasligidir, chunki UV qattiq shtamplovchi jarayoni ongli ravishda sodir bo'ladi. Bu ongli qattiq shtamplovchi imkoniyati tezroq ishlab chiqarish tezligini ta'minlaydi hamda ishlash davomida ranjish yoki ko'chish ehtimolini kamaytiradi. Shuningdek, texnologiya o'zgaruvchan ma'lumotlarni bosishni qo'llab-quvvatlaydi, ya'ni ishlab chiqarish jarayonini sekinlatmay turib, har bir bosilgan mahsulotni moslashtirish va shaxsiylashtirish imkonini beradi. Raqamli UV bosish turli sohalarda, jumladan, ambalajlash, belgilash, targ'ibot materiallari, yorliqlar, avtomobil qismlari, elektronika va me'morlik elementlarida qo'llaniladi. Ushbu bosish usulining moslashuvchanligi qisqa seriyali ishlab chiqarish, namuna tayyorlash yoki talab bo'yicha bosish xizmatlarini talab qiladigan tashkilotlar uchun ayniqsa qimmatli hisoblanadi. Bu texnologiya turli xil materiallarga yorqin ranglar, aniq tafsilotlar va barqaror sifatli bosishni ta'minlashda ustunlik qiladi va zamonaviy bozor talablarini qondiruvchi professional darajadagi bosish echimlarini izlayotgan kompaniyalar uchun zarur vosita hisoblanadi.