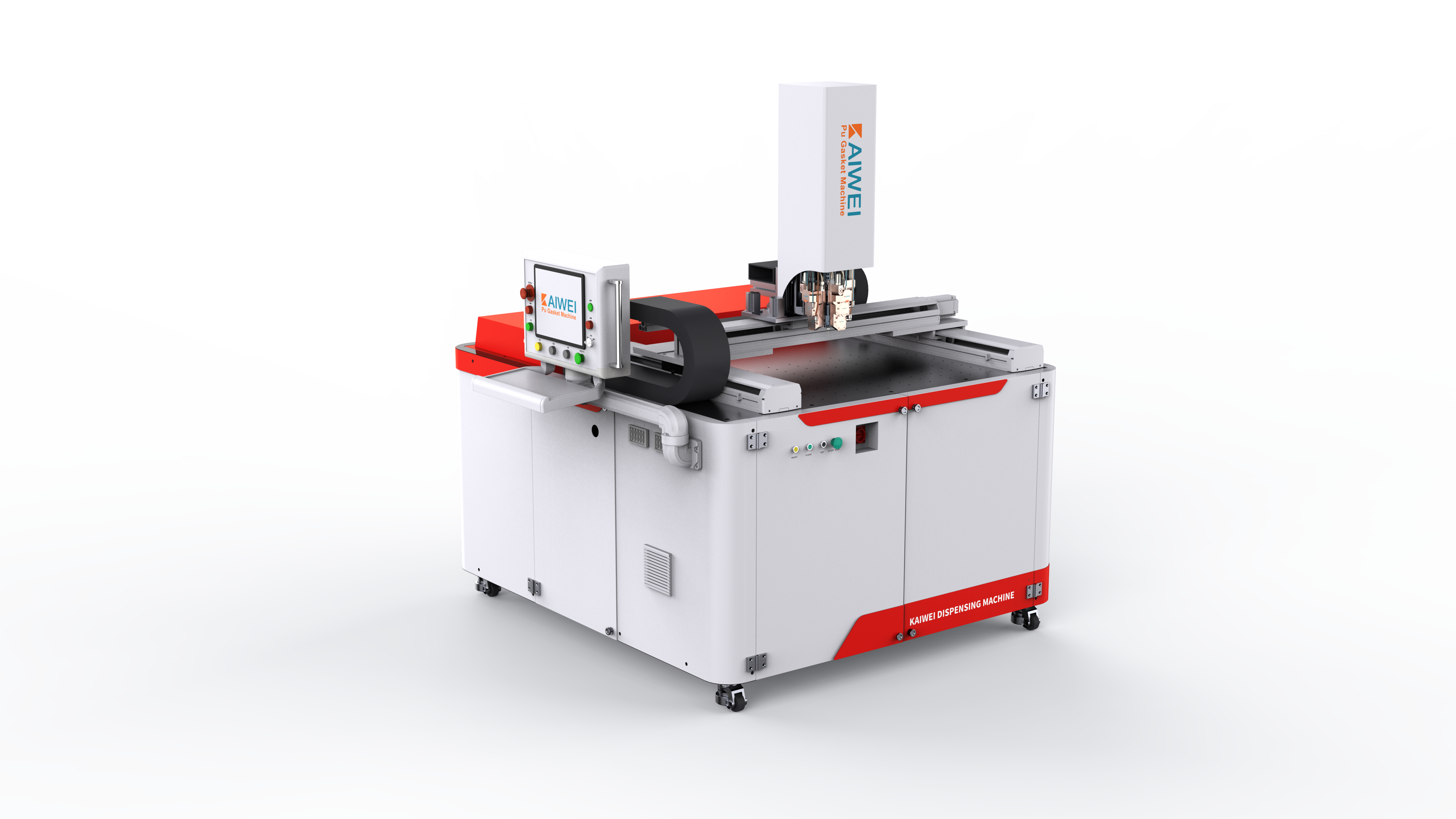

poliuretan qoʻy mashinasi tozalash

Polietilen penoplast mashinalarini uloqtirish polimer ishlab chiqarish texnologiyasidagi inqilobiy yutuq bo'lib, sifatli poliuretan penoplast mahsulotlar talab qilinadigan sohalarning o'sayotgan ehtiyojlariga javob berish uchun mo'ljallangan. Ushbu murakkab mashinalar penoplast ishlab chiqarish operatsiyalarining asosini tashkil etadi va pishish jarayonini aniq boshqarish hamda barqaror chiqish sifatini saqlash imkonini beradi. Poliuretan pishirish mashinasini uloqtirishning asosiy vazifasi poliol va izotsianat komponentlarini aniq aralashtirish va taqsimlashga qaratilgan bo'lib, pishish kengayishini ta'minlovchi kimyoviy reaktsiyani hosil qiladi. Zamonaviy pishirish mashinalari komponentlarning eng yaxshi nisbatini ta'minlaydigan rivojlangan dozalash tizimlarini o'z ichiga oladi, natijada bir xil pishish zichligi va yuqori mexanik xususiyatlarga erishiladi. Ushbu mashinalarning texnik xususiyatlari harorat, bosim va oqim tezligi kabi parametrlarni real vaqtda nazorat qilish va sozlash imkonini beradigan kompyuterlashtirilgan boshqaruv panelini o'z ichiga oladi. Ko'plab poliuretan pishirish mashinalarini uloqtirish turli xildagi pishish turlarini ishlab chiqarish imkonini beradigan ko'p komponentli aralashtirish imkoniyatiga ega, jumladan, mos, qattiq va yarim qattiq formulalarni. Taqsimlash tizimlari yuqori bosimli nasoslardan va aralashtirishdan oldin komponentlarni mukammal aralashtirish uchun aniq aralashtirish boshlaridan foydalanadi. Haroratni boshqarish tizimi ishlab chiqarish siklining davomida optimal ishlash sharoitini saqlaydi, avtomatlashtirilgan tozalash ketma-ketligi esa partiyalar orasida barqaror ishlashni ta'minlaydi. Poliuretan pishirish mashinalarini uloqtirish turli sohalarda, jumladan, avtomobillar ishlab chiqarish, mebellar ishlab chiqarish, binolar izolyatsiyasi, maishiy texnika ishlab chiqarish va boshlovchi echimlarda keng qo'llaniladi. Avtomobil sohasida ushbu mashinalar o'tirish podushkalarini, bosh tayanchlarini va tovushni so'ndiruvchi materiallarni ishlab chiqarish uchun ishlatiladi. Qurilish sanoati izolyatsiya panellarini, tom materiallarini va germetik qo'llanmalarni yaratish uchun poliuretan pishirish mashinalariga tayanadi. Mebel ishlab chiqaruvchilar turli darajadagi qattiklikdagi matratslar, podushkalar va mebel to'ldirgichlarini ishlab chiqarish uchun ushbu tizimlardan foydalanadi. Poliuretan pishirish mashinalarini uloqtirishning ko'p jihatdan qo'llanilishi ularni xarajatlarni tejash va operatsion samaradorlikni saqlab, pishish ishlab chiqarish imkoniyatlarini kengaytirmoqchi bo'lgan korxonalar uchun beqiyos qiladi.