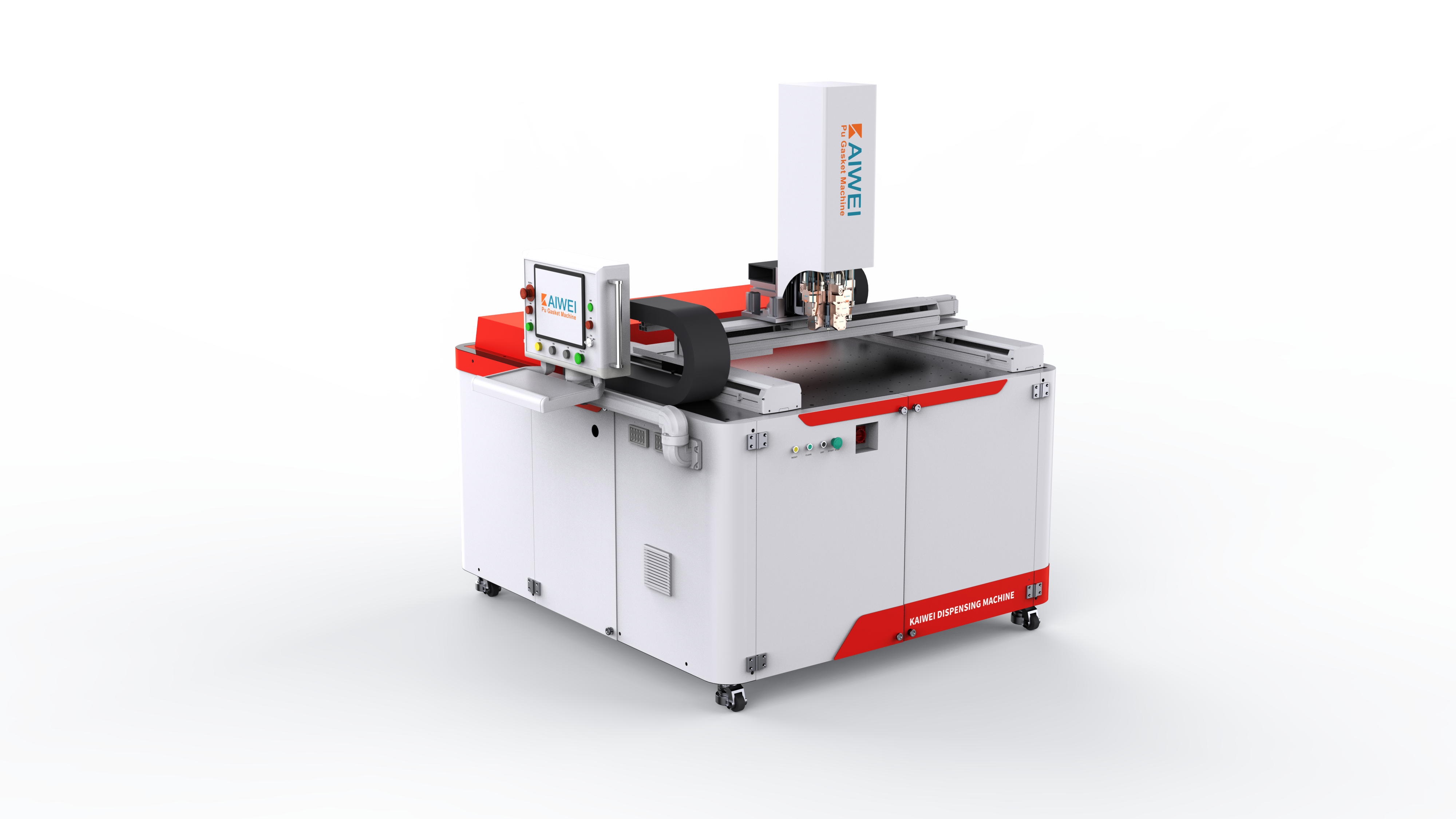

affordable pu gasketing machine

The affordable pu gasketing machine represents a revolutionary advancement in sealing technology, designed specifically for manufacturing industries that require precision gasket production without breaking their budget. This innovative equipment combines cutting-edge polyurethane dispensing technology with cost-effective engineering to deliver professional-grade results at an accessible price point. The machine features a robust dispensing system that accurately applies polyurethane materials to create durable, weather-resistant gaskets for various industrial applications. Its automated control system ensures consistent bead placement and thickness, eliminating human error while maintaining production speed. The affordable pu gasketing machine incorporates advanced mixing technology that blends two-component polyurethane materials in real-time, ensuring optimal chemical reactions and superior bond strength. The equipment includes programmable logic controllers that allow operators to customize dispensing patterns, speeds, and volumes according to specific project requirements. Temperature control systems maintain optimal material viscosity throughout the production process, while pressure regulation ensures smooth, uninterrupted flow. The machine's modular design facilitates easy maintenance and component replacement, reducing downtime and operational costs. Safety features include emergency stops, protective guards, and automatic material shut-off systems to protect operators during operation. The affordable pu gasketing machine supports various substrate materials including metal, plastic, glass, and composite materials, making it versatile for diverse manufacturing environments. Quality monitoring systems provide real-time feedback on material flow rates, pressure levels, and temperature readings, enabling operators to maintain consistent output quality. The equipment's compact footprint makes it suitable for facilities with limited floor space, while its energy-efficient operation reduces power consumption costs. Integration capabilities allow seamless connection with existing production lines and quality control systems. This affordable pu gasketing machine delivers professional sealing solutions that meet industry standards while maintaining budget-friendly operational costs.