pu gasketing machine price

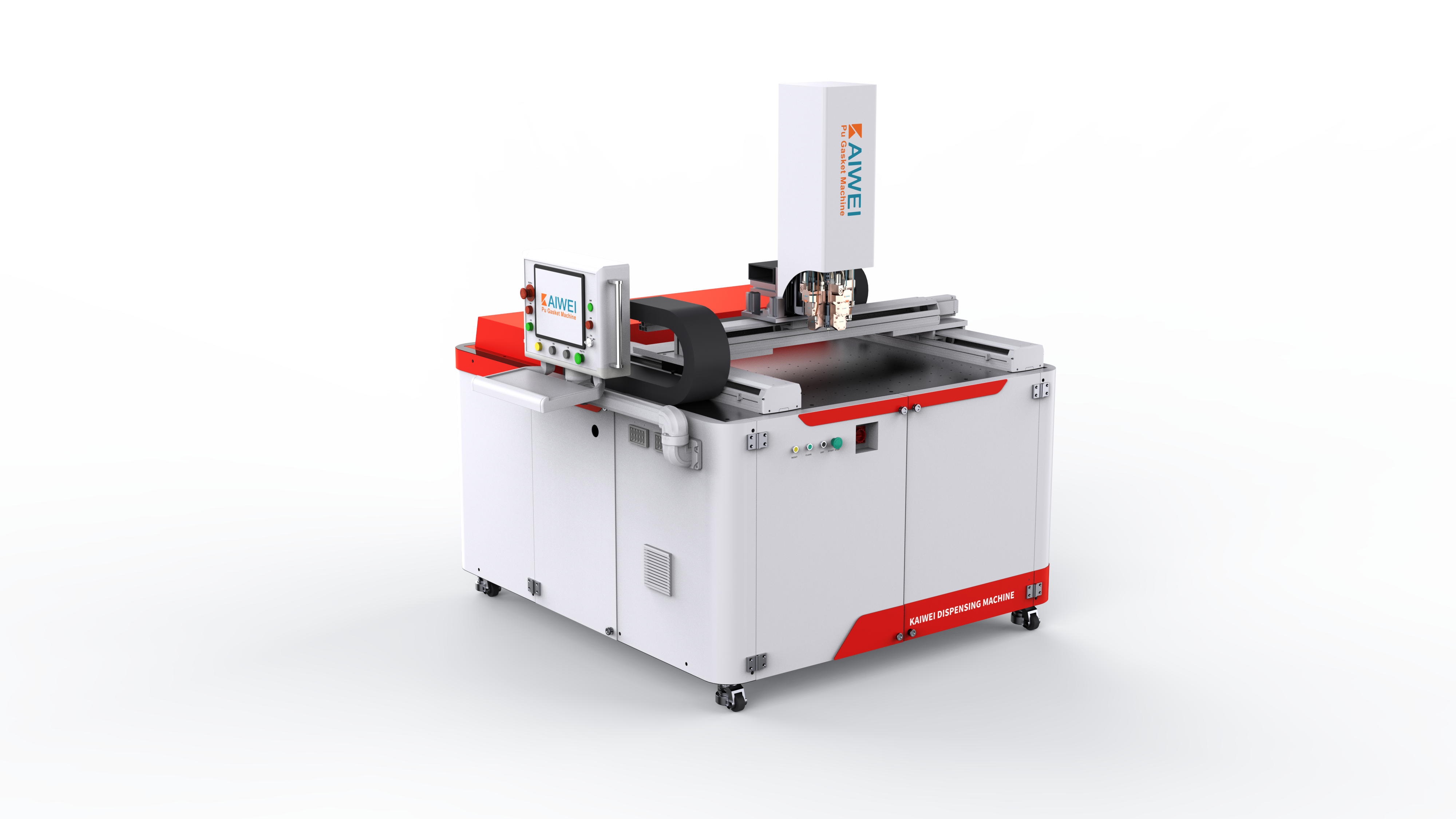

The PU gasketing machine price represents a significant investment in manufacturing technology that delivers exceptional value for businesses requiring precise sealing solutions. These sophisticated machines specialize in applying polyurethane gaskets to various products, ensuring superior sealing performance across multiple industries. When evaluating the PU gasketing machine price, manufacturers must consider the comprehensive capabilities these systems offer, including automated dispensing, precise positioning, and consistent application quality. Modern PU gasketing machines incorporate advanced control systems that manage temperature, pressure, and flow rate with remarkable accuracy. The main functions encompass material heating, mixing, dispensing, and curing processes, all controlled through intuitive interfaces that minimize operator training requirements. Technological features include servo-driven dispensing heads, programmable logic controllers, and real-time monitoring systems that ensure consistent gasket application. The PU gasketing machine price reflects sophisticated engineering that enables production of gaskets with varying hardness levels, from soft flexible seals to rigid structural components. Applications span automotive manufacturing, electronics enclosures, appliance production, and construction materials where reliable sealing performance is critical. These machines handle complex gasket geometries, including intricate patterns and multi-dimensional profiles that would be impossible to achieve manually. Temperature control systems maintain optimal polyurethane viscosity throughout production cycles, while automated cleaning functions reduce downtime between different material formulations. The PU gasketing machine price encompasses comprehensive safety features, including emergency stops, protective enclosures, and ventilation systems that protect operators from chemical exposure. Quality assurance capabilities include thickness monitoring, adhesion testing, and automated reject systems that maintain production standards. Investment in PU gasketing technology translates to reduced labor costs, improved product consistency, and enhanced production capacity that justifies the initial PU gasketing machine price through long-term operational benefits.