polyurethane foaming machine manufacturer

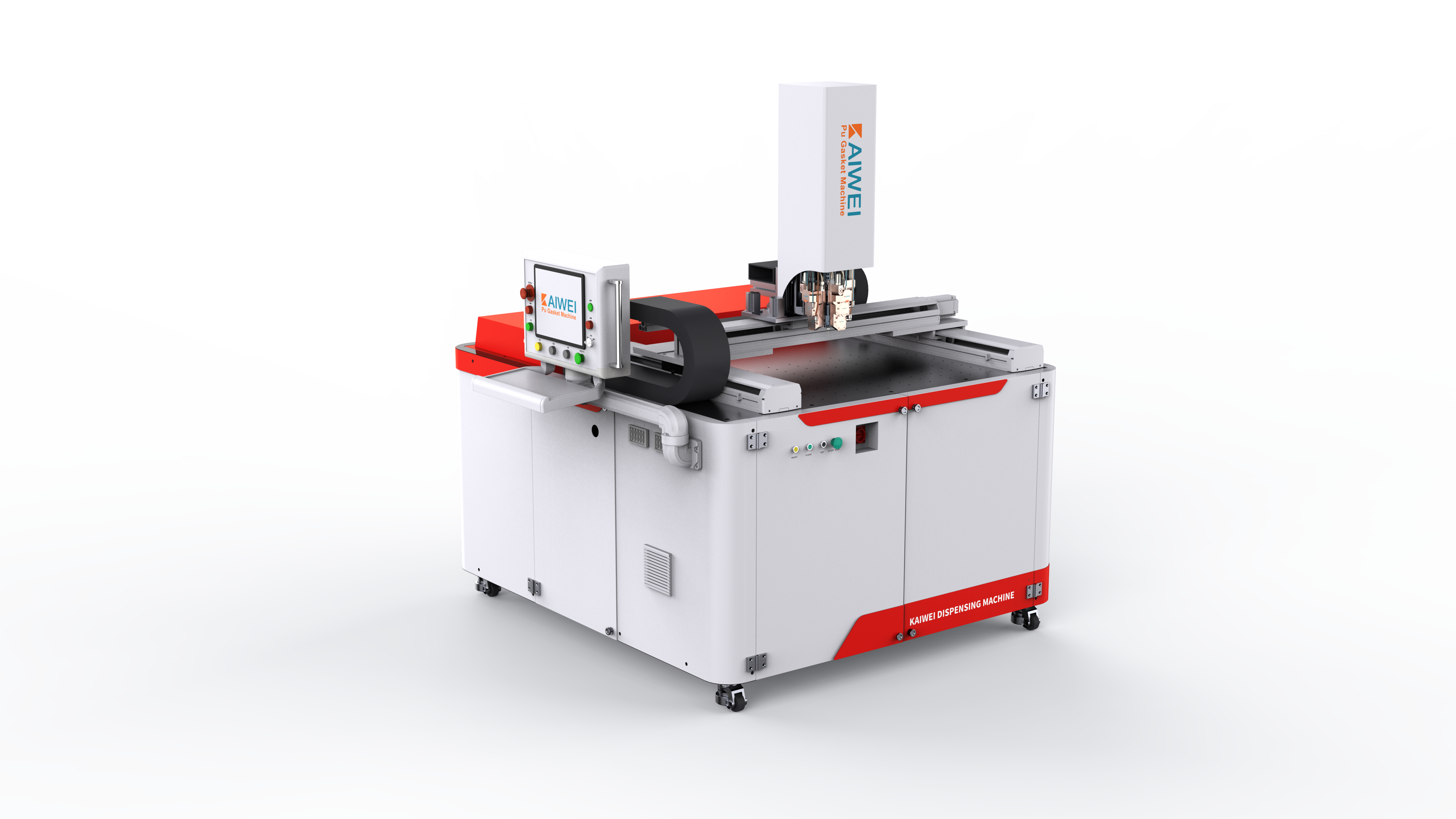

A polyurethane foaming machine manufacturer represents a crucial industrial supplier that designs, produces, and distributes specialized equipment for polyurethane foam production. These manufacturers engineer sophisticated machinery capable of mixing, dispensing, and controlling the chemical reactions necessary for creating high-quality polyurethane foam products. The primary function of equipment from a polyurethane foaming machine manufacturer involves precisely combining polyol and isocyanate components with catalysts, blowing agents, and additives to create foam with specific density, hardness, and structural properties. Modern polyurethane foaming machine manufacturers incorporate advanced control systems that monitor temperature, pressure, and mixing ratios to ensure consistent foam quality across production runs. The technological features typically include programmable logic controllers, touchscreen interfaces, automated material handling systems, and real-time monitoring capabilities that allow operators to adjust parameters instantly. These manufacturers serve diverse industries including automotive, furniture, construction, appliance, and packaging sectors where polyurethane foam applications are essential. The equipment produced by a polyurethane foaming machine manufacturer ranges from small-scale laboratory units to large industrial production lines capable of producing thousands of foam parts daily. Advanced manufacturers integrate Industry 4.0 technologies, enabling remote monitoring, predictive maintenance, and data analytics to optimize production efficiency. Environmental considerations have become increasingly important, with leading polyurethane foaming machine manufacturers developing eco-friendly solutions that minimize waste, reduce energy consumption, and support sustainable manufacturing practices. Quality assurance systems ensure that machines meet international standards and safety regulations while maintaining precise control over foam characteristics such as cell structure, thermal properties, and mechanical strength.