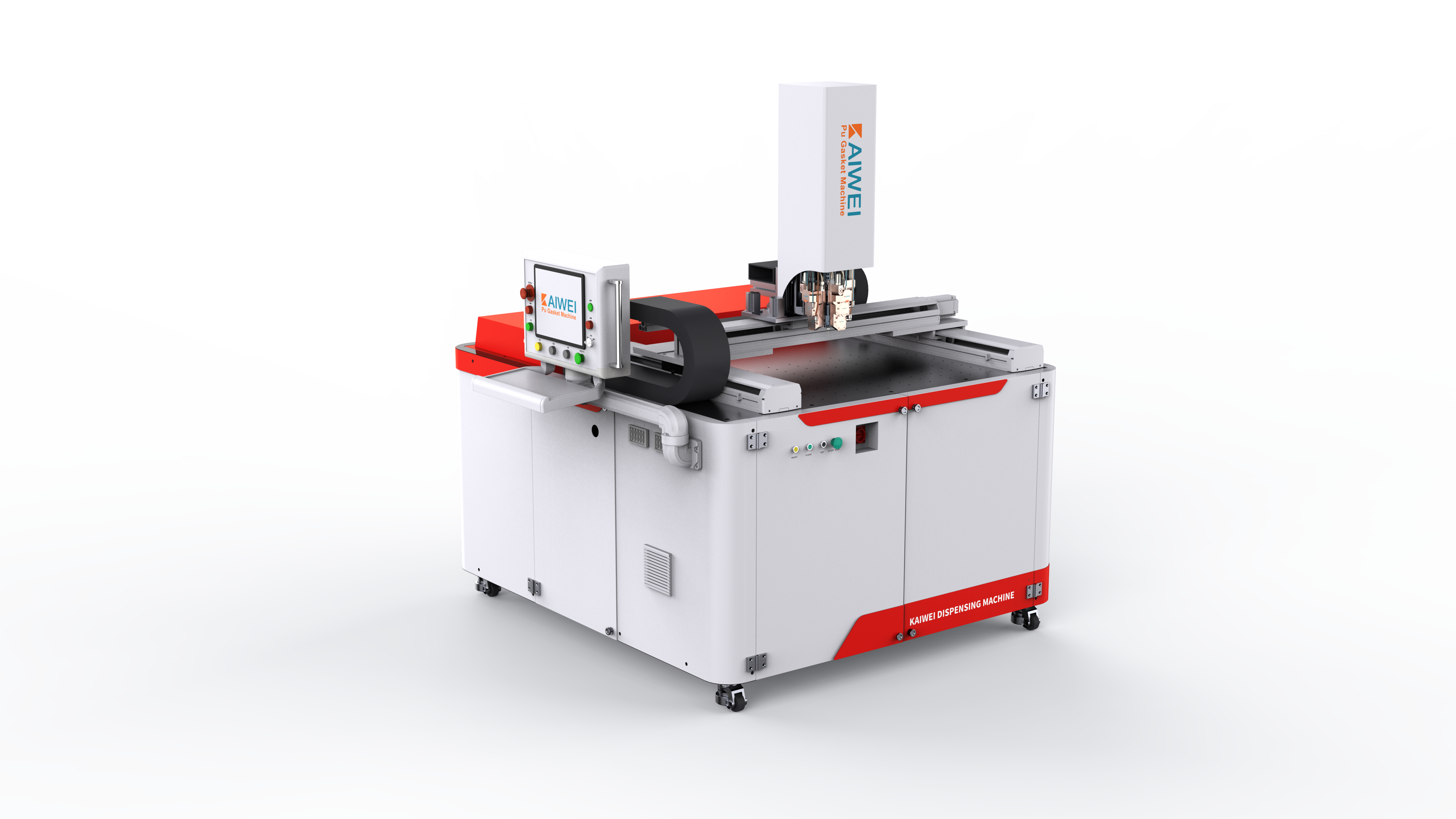

polyuretaanipuumauslaitteen valmistaja

Polyuretaanivaahtokoneiden valmistaja on keskeinen teollinen toimittaja, joka suunnittelee, tuottaa ja myy erikoistunutta varustusta polyuretaanivaahtojen valmistukseen. Nämä valmistajat kehittävät edistyneitä koneita, jotka pystyvät sekoittamaan, jakamaan ja hallitsemaan kemiallisia reaktioita, joita tarvitaan korkealaatuisten polyuretaanivaahtotuotteiden valmistukseen. Polyuretaanivaahtokoneiden valmistajan laitteiden ensisijainen tehtävä on yhdistää tarkasti polyolit ja isosyanataatit katalyyttien, vaahtoaineiden ja lisäaineiden kanssa luodakseen vaahtoa, jolla on tietty tiheys, kovuus ja rakenteelliset ominaisuudet. Nykyaikaiset polyuretaanivaahtokoneiden valmistajat käyttävät edistyneitä ohjausjärjestelmiä, jotka valvovat lämpötilaa, painetta ja sekoitusmääriä varmistaakseen vaahton laadun yhtenäisyyden tuotantosarjojen aikana. Teknisiin ominaisuuksiin kuuluu tyypillisesti ohjelmoitavat logiikkasäätimet, kosketusnäytöt, automatisoidut materiaalien käsittelyjärjestelmät ja reaaliaikaiset valvontamahdollisuudet, joiden avulla käyttäjät voivat säätää parametreja välittömästi. Nämä valmistajat palvelevat monia eri aloja, kuten auto-, huonekalu-, rakennus-, kodinkone- ja pakkausteollisuutta, joissa polyuretaanivaahtojen sovellukset ovat olennaisia. Polyuretaanivaahtokoneiden valmistajan tuottamat laitteet vaihtelevat pienimuotoisista laboratoriokoneista suuriin teollisiin tuotantolinjoihin, jotka pystyvät tuottamaan tuhansia vaahtotuotteita päivässä. Edistykselliset valmistajat integroivat Industry 4.0 -tekniikat mahdollistaen etävalvonnan, ennakoivan huollon ja tietojen analysoinnin tuotannon tehokkuuden optimoimiseksi. Ympäristönäkökohdat ovat yhä tärkeämpiä, ja alan johtavat polyuretaanivaahtokoneiden valmistajat kehittävät ympäristöystävällisiä ratkaisuja, jotka minimoivat jätteen, vähentävät energiankulutusta ja edistävät kestävää valmistusta. Laadunvarmistusjärjestelmät takaa, että koneet täyttävät kansainväliset standardit ja turvallisuusmääräykset samalla kun ne säilyttävät tarkan hallinnan vaahton ominaisuuksissa, kuten solurakenteessa, lämpöominaisuuksissa ja mekaanisessa lujuudessa.