pu foam machine price

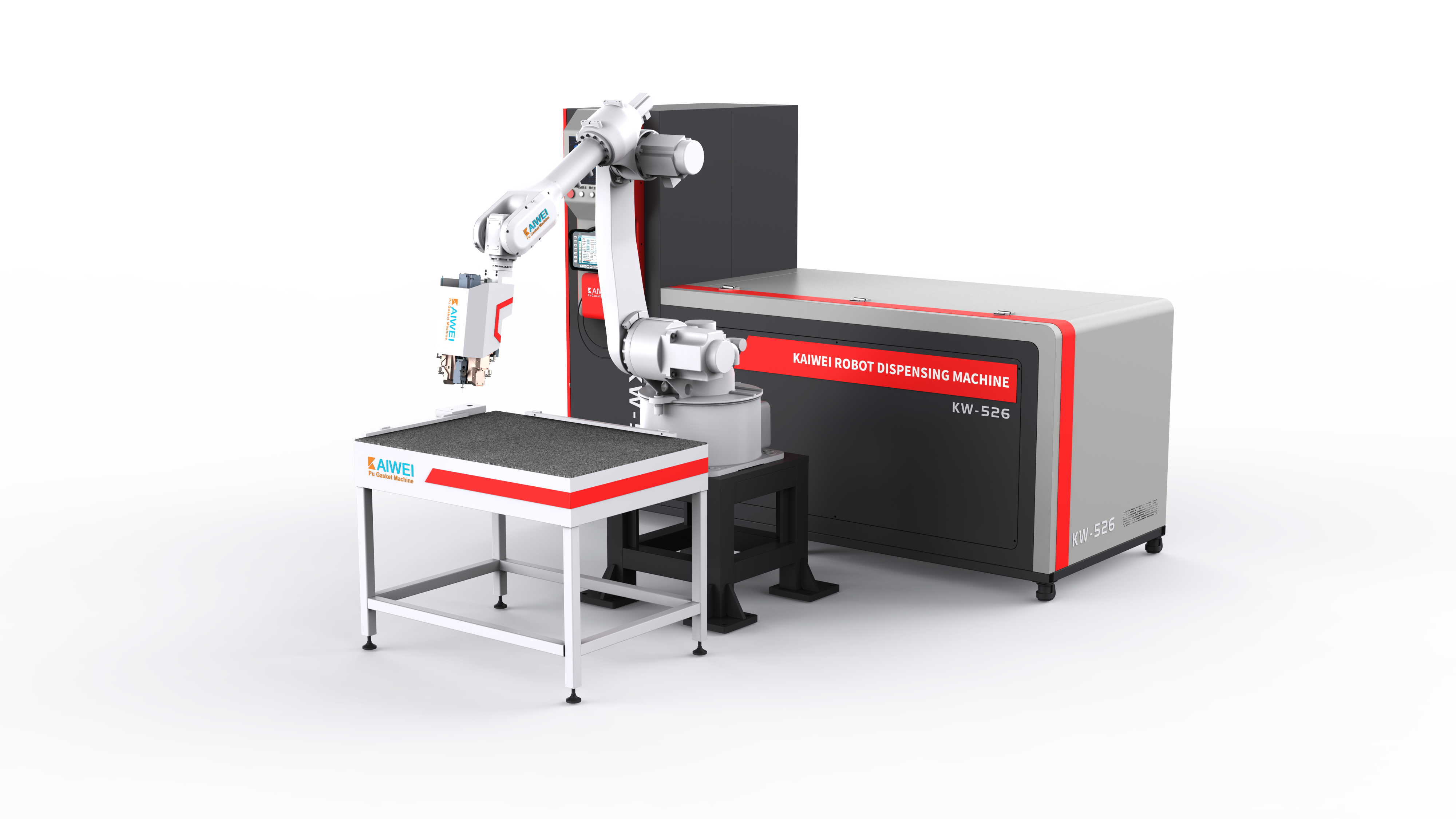

Understanding PU foam machine price represents a crucial investment decision for manufacturers across diverse industries. These sophisticated polyurethane foam dispensing systems transform liquid components into high-quality foam products through precise mixing and application processes. The PU foam machine price varies significantly based on technological sophistication, production capacity, and automation features. Modern PU foam machines incorporate advanced control systems that monitor temperature, pressure, and mixing ratios to ensure consistent foam quality. Their main functions include accurate component metering, thorough mixing of polyol and isocyanate, controlled foam dispensing, and automated production cycles. These machines excel in producing flexible foams for automotive seating, rigid foams for insulation panels, and specialty foams for packaging applications. Technological features distinguishing premium models include servo-driven pumps, touchscreen interfaces, recipe storage capabilities, and real-time quality monitoring systems. The PU foam machine price reflects these advanced features, with entry-level models starting around $15,000 while industrial-grade systems can exceed $200,000. Applications span automotive manufacturing, construction materials, furniture production, appliance insulation, and packaging solutions. When evaluating PU foam machine price, consider factors such as daily output requirements, foam density specifications, and integration needs with existing production lines. Modern machines offer energy-efficient operations, reducing long-term operational costs despite higher initial PU foam machine price investments. Quality manufacturers provide comprehensive training, technical support, and maintenance services that justify premium pricing. The PU foam machine price should be viewed as a long-term investment in production capability, product quality consistency, and operational efficiency gains.