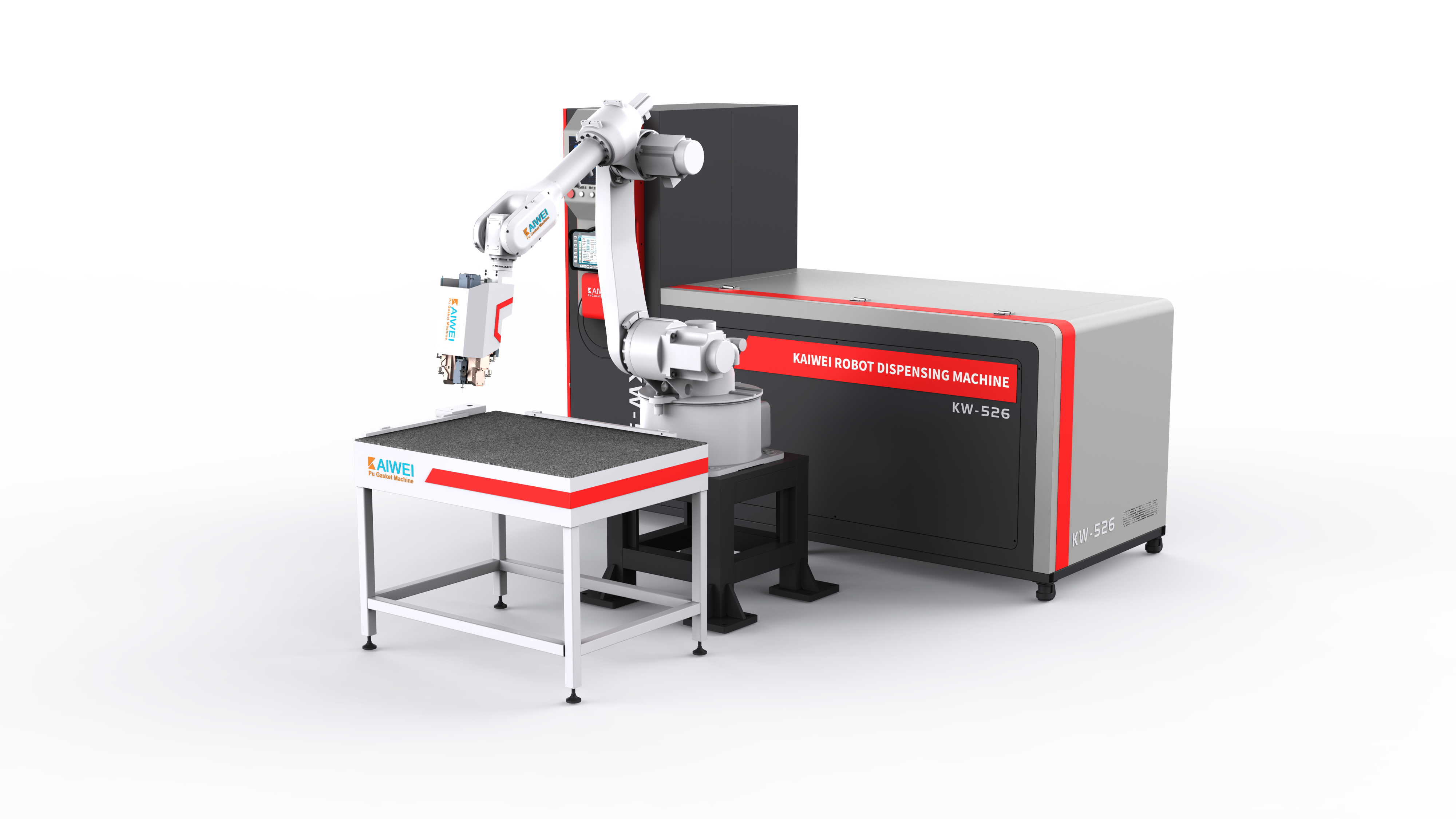

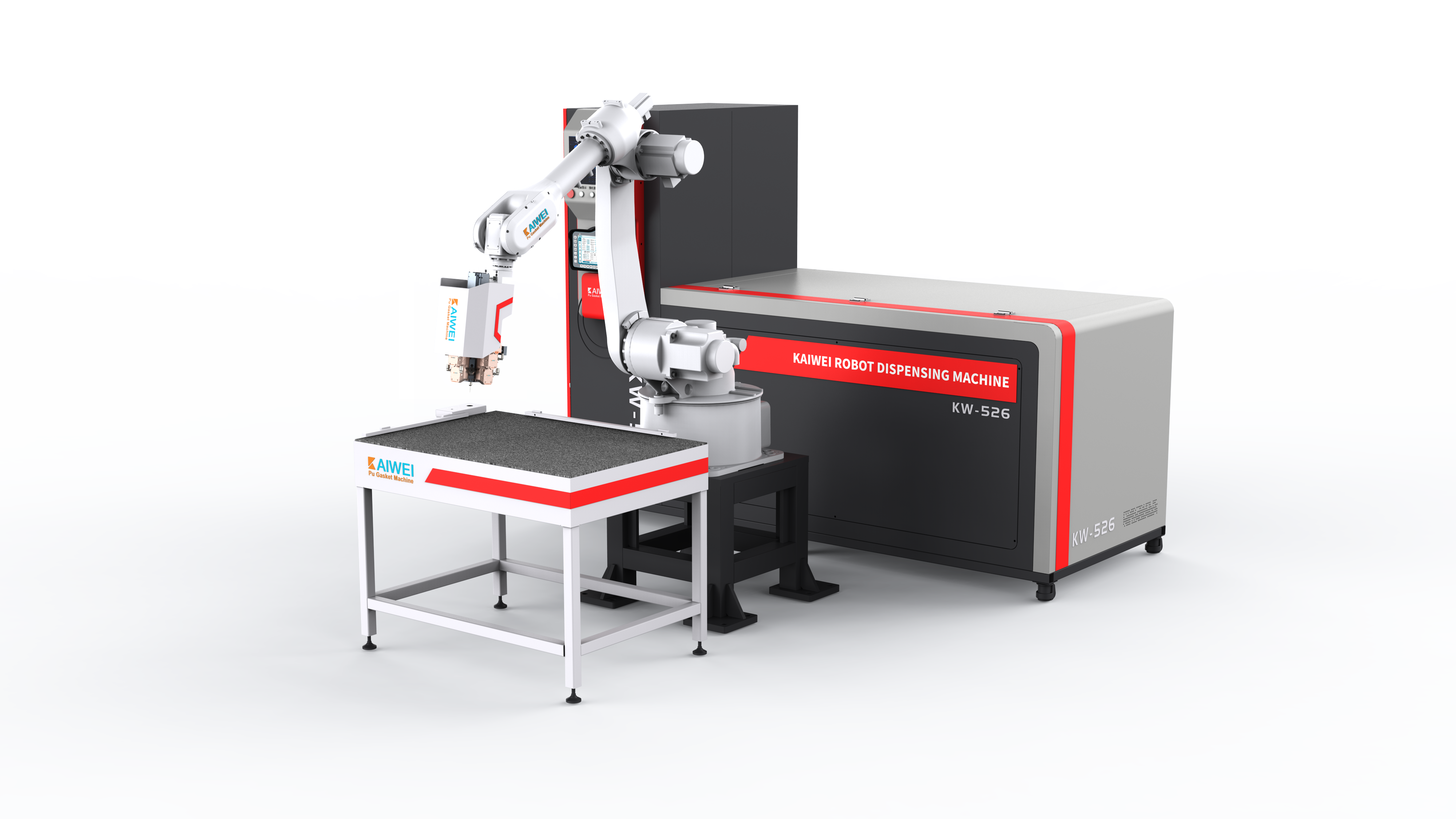

Exceptional Versatility and Adaptability

The exceptional versatility built into each pu foaming machine for sale enables manufacturers to produce an extensive range of foam products using a single piece of equipment, maximizing return on investment while minimizing floor space requirements. This adaptability stems from the machine's ability to handle various polyurethane formulations, from rigid structural foams used in construction applications to flexible foams for comfort and cushioning products. The adjustable mixing chamber accommodates different batch sizes, allowing production flexibility that ranges from small prototype runs to large-scale manufacturing operations. Component ratio adjustments enable the creation of foams with vastly different properties, including density variations from lightweight insulation materials to high-density structural components. The heating system adapts to different formulation requirements, maintaining optimal processing temperatures for various chemical systems and cure profiles. Mold compatibility extends across multiple industries, with the pu foaming machine for sale accepting standard automotive, furniture, construction, and packaging molds without modification. The dispensing system adjusts flow rates and pressure settings to accommodate different application methods, whether pour-in-place, injection molding, or continuous production processes. Color matching capabilities allow for consistent pigmentation across production runs, essential for visible applications where aesthetic consistency matters. The machine's software accommodates unlimited recipe storage, enabling manufacturers to maintain libraries of proven formulations for different customers or applications. Quick changeover features minimize downtime when switching between products, with automated cleaning cycles that prepare the system for different formulations efficiently. Seasonal production adjustments become seamless, as the pu foaming machine for sale adapts to varying ambient conditions and raw material properties that change with temperature and humidity fluctuations. The expandable architecture allows for future upgrades and additional features, ensuring the equipment remains relevant as business needs evolve. Training requirements remain minimal due to the intuitive interface design, enabling operators to master multiple product lines quickly and efficiently.