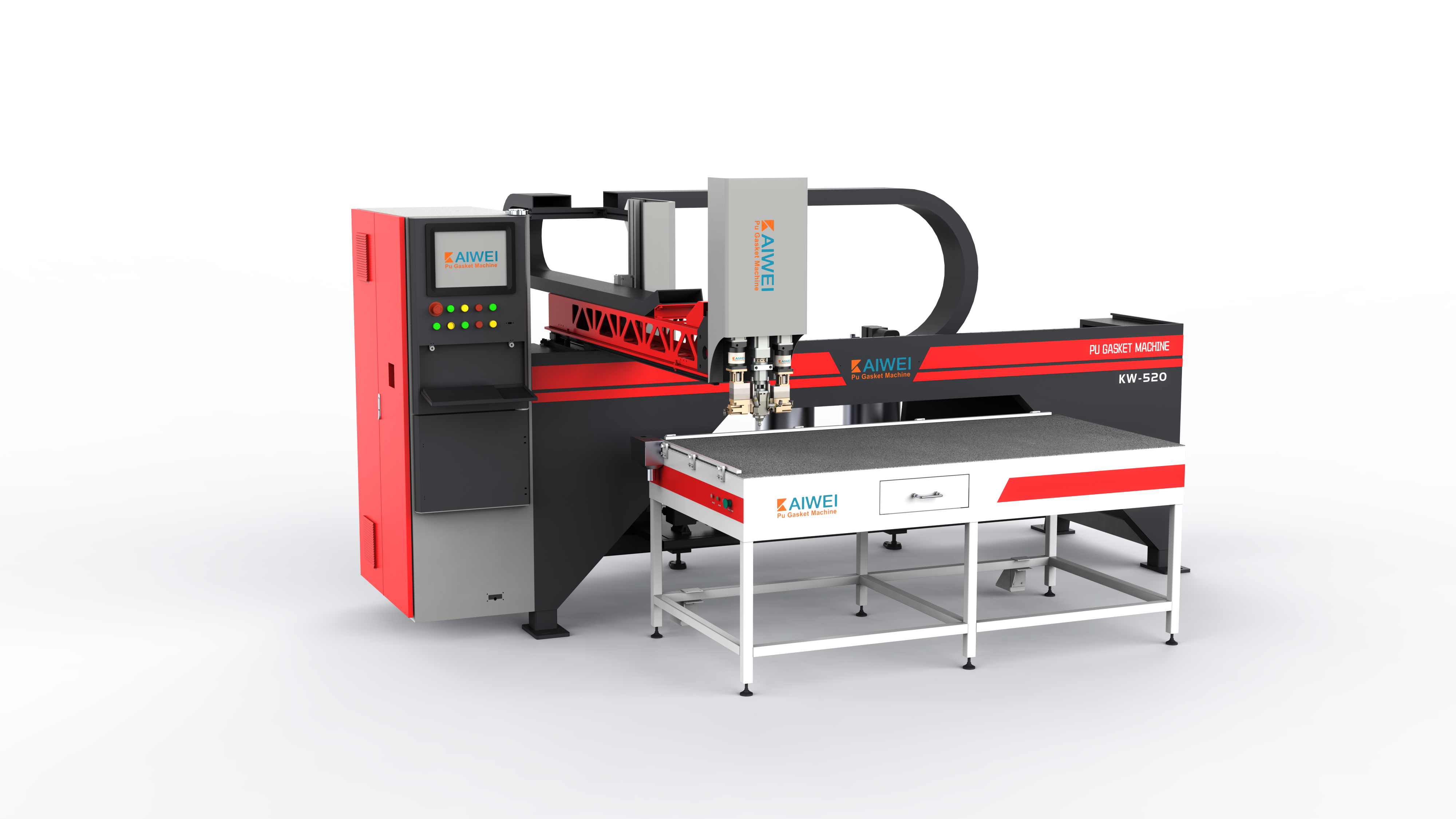

the polyurethane glue dispenser

The polyurethane glue dispenser represents a sophisticated industrial solution designed to deliver precise, controlled application of polyurethane adhesives across diverse manufacturing environments. This specialized equipment combines advanced mechanical engineering with digital control systems to ensure consistent dispensing performance in high-volume production settings. Modern polyurethane glue dispensers feature robust construction capable of handling various viscosities and formulations of polyurethane-based adhesives, from low-viscosity reactive systems to high-viscosity structural bonding compounds. The core functionality revolves around maintaining optimal material flow rates while preventing contamination and waste during the dispensing process. These systems typically incorporate heated material paths to maintain proper working temperatures for temperature-sensitive polyurethane formulations. Advanced dispensers include programmable logic controllers that allow operators to establish custom dispensing patterns, adjust flow rates, and monitor system performance through integrated displays. Material handling capabilities extend to both single-component and two-component polyurethane systems, with specialized mixing chambers ensuring proper chemical ratios when required. Safety features include emergency stop mechanisms, material containment systems, and ventilation compatibility for handling volatile components. The equipment finds extensive use in automotive manufacturing for sealing applications, construction industry for structural bonding, packaging sector for flexible adhesive applications, and electronics manufacturing for component encapsulation. Installation flexibility allows integration into existing production lines or standalone operation depending on specific requirements. Maintenance protocols are streamlined through accessible component design and diagnostic capabilities that identify potential issues before they impact production efficiency.