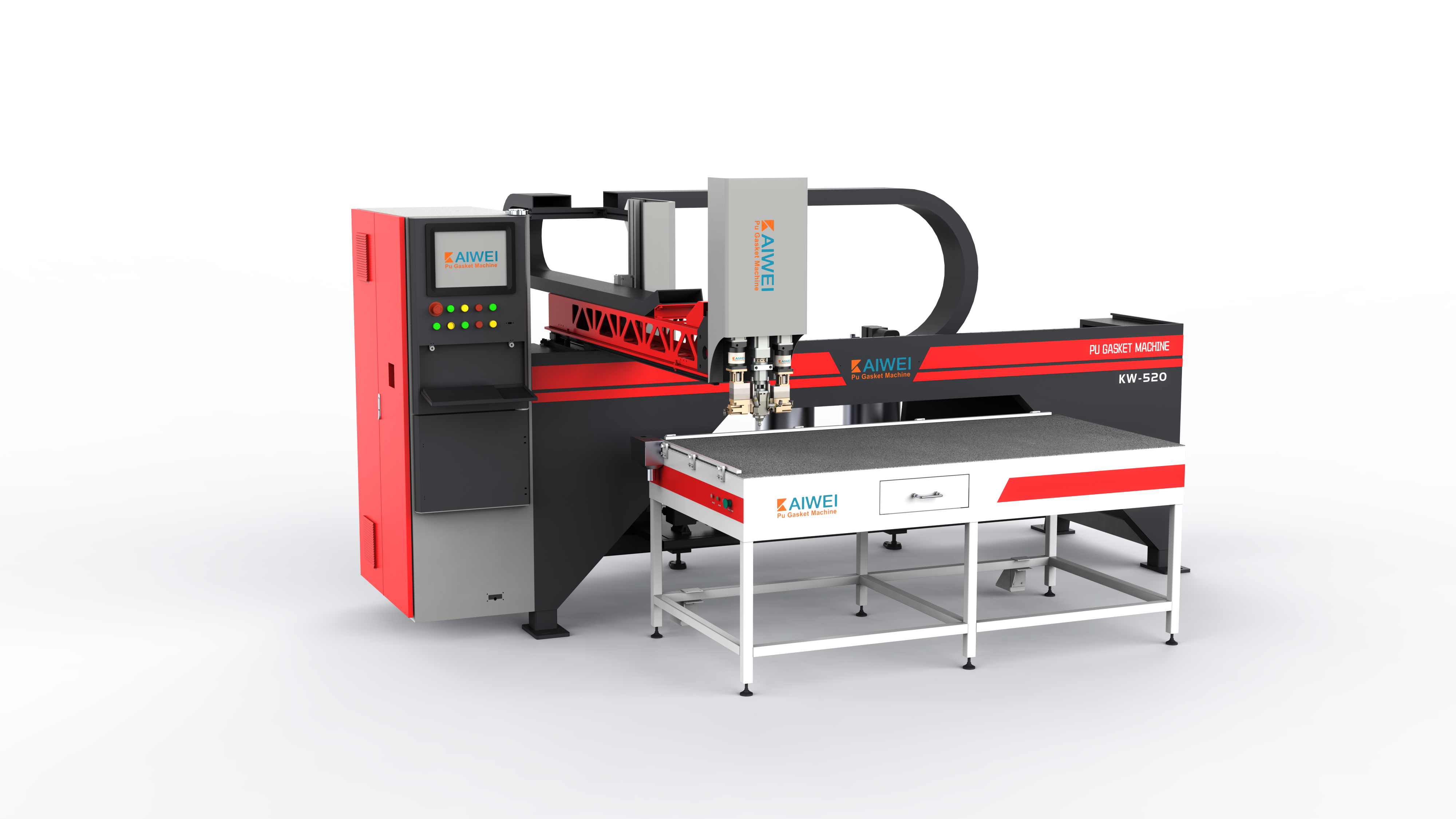

Edistynyt digitaalinen ohjausjärjestelmä parhaan suorituskyvyn saavuttamiseksi

Polyuretaaniliimannäyttelevä laite sisältää kehittynyttä digitaalista ohjausteknologiaa, joka vallankkaa liimausprosesseja teollisissa valmistusympäristöissä. Tämä edistynyt ohjausjärjestelmä sisältää mikroprosessoripohjaiset ohjelmoitavuusominaisuudet, jotka mahdollistavat tarkan annostelun parametrien määrittämisen tuotannon erityisten vaatimusten mukaisesti. Digitaalinen käyttöliittymä tarjoaa reaaliaikaisen seurannan keskeisille muuttujille, kuten virtausnopeudelle, paineelle, lämpötilalle ja materiaalin tilavuudelle, varmistaen tasaisen suorituskyvyn pitkien tuotantokatkosten ajan. Kosketusnäytöt tarjoavat intuitiiviset navigaatiomenuvalikon, joka yksinkertaistaa parametrien säätöä ja järjestelmän konfigurointia, vähentäen koulutustarvetta ja minimoimalla käyttäjävirheet. Ohjausjärjestelmä tallentaa useita annosteluprogrammeja, mikä mahdollistaa nopean vaihto-eron eri tuotteiden tai liimaformulointien välillä ilman manuaalista uudelleenkalibrointia. Automaattiset takaisinkytkentäpiirit seuraavat jatkuvasti todellista annostelusuoritusta verrattuna ohjelmoituihin määrityksiin, tekemällä reaaliaikaisia säätöjä optimaalisen tuloksen laatutasapainon ylläpitämiseksi. Tietojen tallennusominaisuudet kirjaavat toiminnalliset parametrit laadunvarmistusasiakirjoihin ja prosessin optimointianalyysiin. Etäseurantavaihtoehdot mahdollistavat valvontahenkilökunnan seurata useita annostelupisteitä keskitetyistä paikoista, parantaen valvontaa ja reagointiaika-aikaa mahdollisiin toiminnallisiin ongelmiin. Järjestelmä sisältää ennakoivan huoltamisen algoritmit, jotka analysoivat suorituskyvyn trendejä ja komponenttien kulutuksen mallit palvelutoimintojen ajoituksen ennen laiterikkoja. Turvallisuuslukot estävät toiminnan ulkopuolella vakiintuneita parametreja, suojelevat sekä laitetta että käyttäjiä samalla kun ylläpitävät tuotteen laadun vakioita. Integrointiominaisuudet mahdollistavat ohjausjärjestelmän viestintään laajempien tehdasautomaatioverkkojen kanssa, tukevat Industry 4.0 -aloitteita ja kattavaa tuotannonhallintajärjestelmiä. Edistyneet diagnostiikkatoiminnot tarjoavat yksityiskohtaista vianetsintätietoa, joka vähentää huoltokatkoja ja varmistaa teknisten ongelmien nopean ratkaisun.