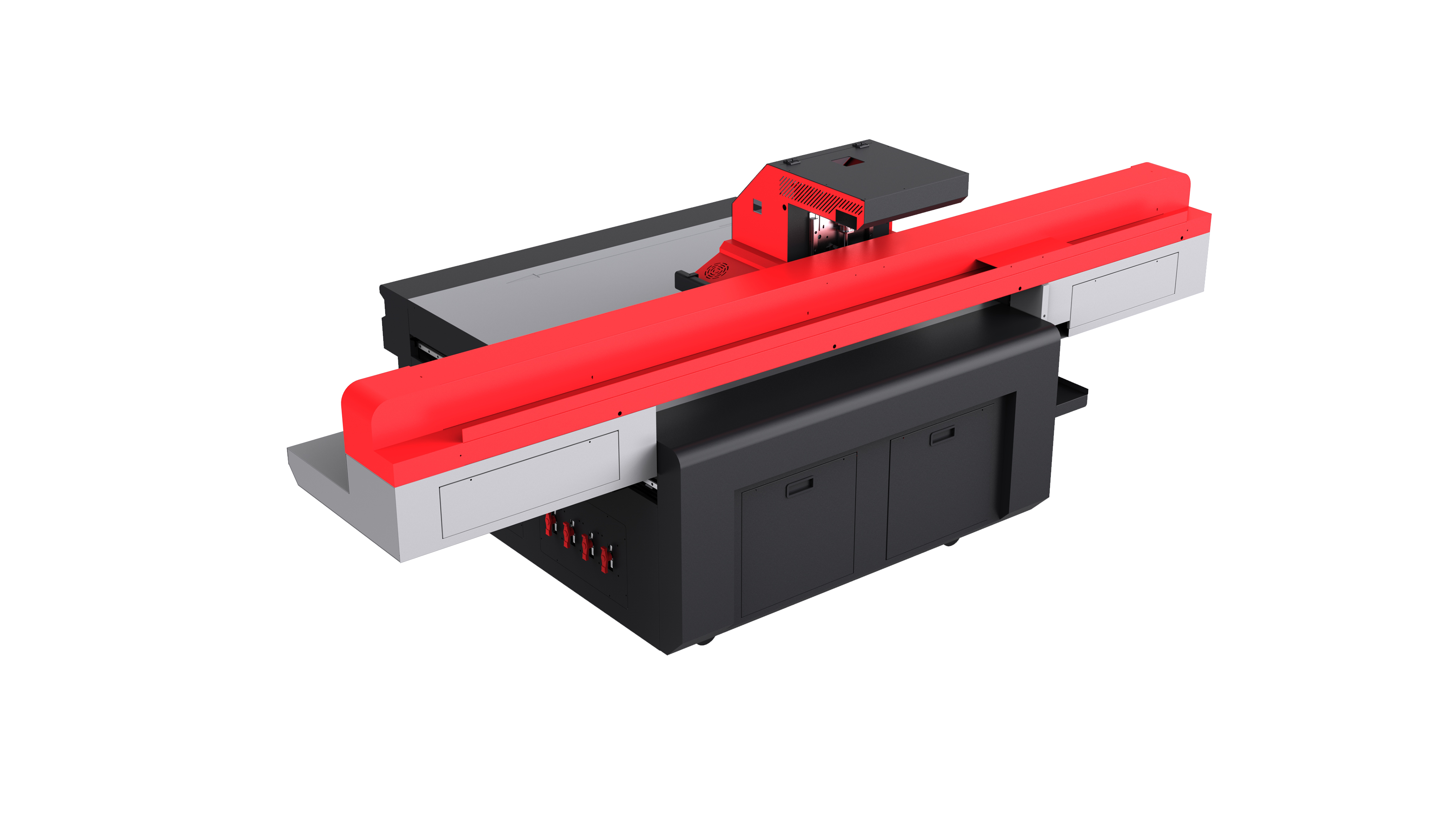

چاپگر دیجیتال UV ارزان قیمت

یک چاپگر دیجیتال UV کمهزینه نوآوری انقلابی در فناوری چاپ مدرن محسوب میشود و نقطه شروع مقرونبهصرفهای برای دسترسی کسبوکارها و متخصصان خلاق به راهحلهای چاپ UV با کیفیت بالا فراهم میکند. این تجهیزات نوآورانه از فناوری خشککننده با نور ماوراء بنفش استفاده میکنند تا جوهرهای مخصوص فرمولهشده UV را بلافاصله خشک و پخت کنند و چاپهایی با دوام و رنگهای زنده روی طیف گستردهای از مواد اولیه ایجاد نمایند. چاپگر دیجیتال UV کمهزینه، قابلیتهای پیشرفته چاپ را با قیمتی مقرونبهصرفه ترکیب میکند و چاپ در سطح حرفهای را برای کسبوکارهای کوچک، استارتآپها و کارآفرینان انفرادی که قبلاً قادر به تأمین هزینه این فناوری نبودند، در دسترس قرار میدهد. این چاپگرها از هد چاپ پیزوالکتریک پیشرفته بهره میبرند که دقت و ثبات استثنایی را فراهم میکند و اطمینان حاصل میشود که هر چاپ مطابق استانداردهای حرفهای باشد. فرآیند پخت UV نیاز به زمان خشکشدن سنتی را حذف میکند و بهطور چشمگیری بهرهوری و ظرفیت تولید را افزایش میدهد. اغلب مدلهای چاپگر دیجیتال UV کمهزینه از پیکربندیهای چندین جوهر از جمله CMYK به علاوه گزینههای جوهر سفید و وارنیش پشتیبانی میکنند و به کاربران اجازه میدهند اثرات بصری و بافتهای شگفتانگیزی ایجاد کنند. این فناوری هم با مواد صلب و هم انعطافپذیر سازگار است، از کاغذ و مقواهای سنتی گرفته تا مواد غیرمعمول مانند شیشه، فلز، پلاستیک، چوب و پارچه. سیستمهای پیشرفته مدیریت رنگ، تولید رنگ دقیق را روی مواد مختلف تضمین میکنند، در حالی که قابلیت چاپ داده متغیر امکان شخصیسازی و سفارشیسازی در مقیاس را فراهم میآورد. چاپگر دیجیتال UV کمهزینه معمولاً شامل رابطهای نرمافزاری کاربرپسند است که مدیریت گردش کار، صف کارها و فرآیندهای اصلاح رنگ را ساده میکند. سیستمهای پخت UV با LED کممصرف، هزینههای عملیاتی را کاهش میدهند و در عین حال کیفیت چاپ عالی را حفظ میکنند. این چاپگرها اغلب دارای تشخیص خودکار محیط چاپ، سیستمهای تمیزکننده هد چاپ و مکانیسمهای پیشرفته گردش جوهر هستند که نیاز به نگهداری را به حداقل میرسانند و زمان کارکرد مؤثر را به حداکثر میرسانند و آنها را به گزینهای ایدهآل برای کسبوکارهایی که به دنبال راهحلهای چاپ قابل اعتماد و کمهزینه بدون قربانی کردن کیفیت خروجی حرفهای هستند، تبدیل میکنند.