کدام صنایع بیشترین استفاده را از فناوری آببندی با فوم میبرند؟

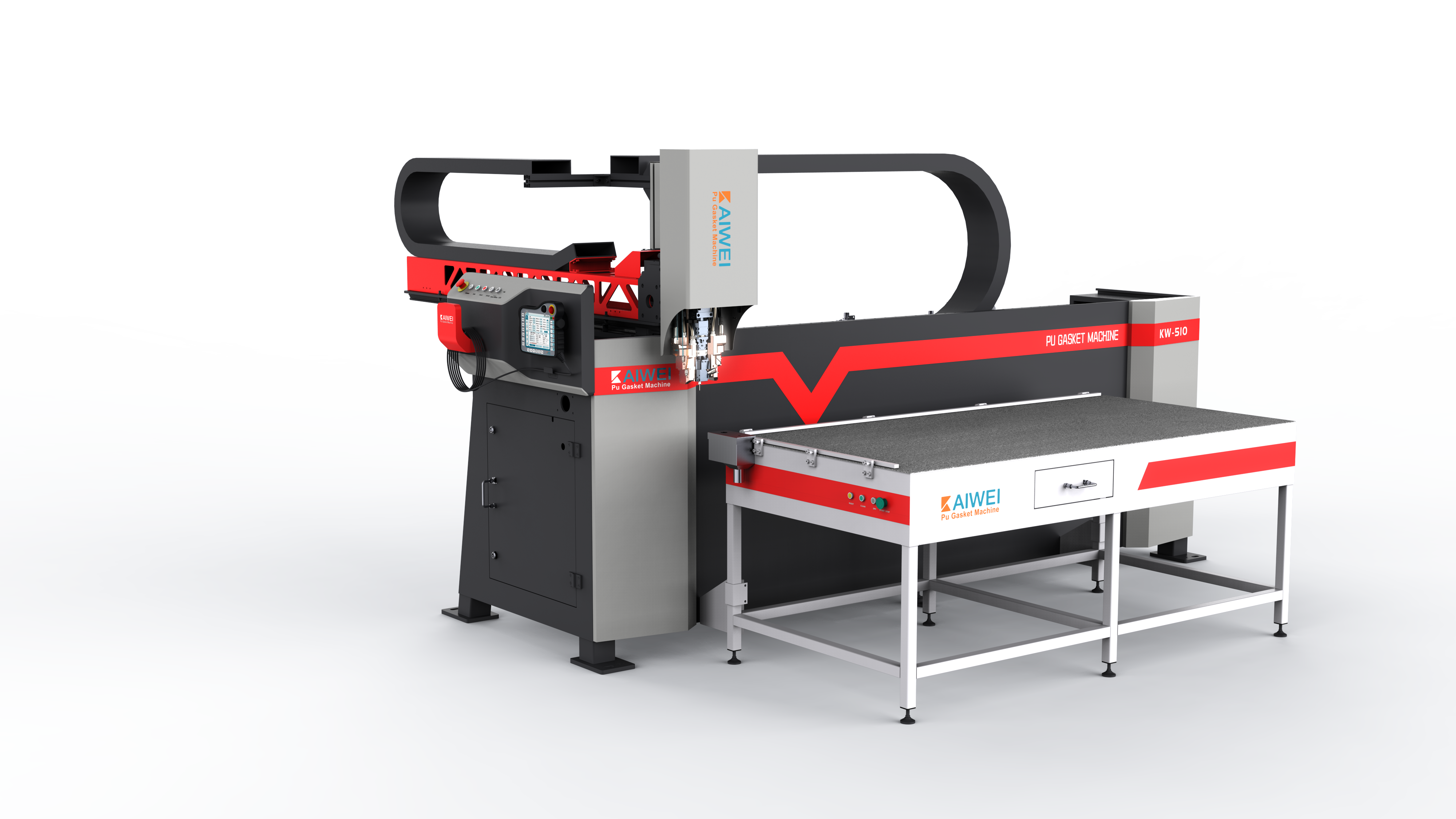

اهمیت رو به رشد مهر و موم فوم در تولید و تولید فن آوری مهر و موم فوم به بخشی حیاتی از فرآیندهای تولید مدرن در طیف گسترده ای از صنایع تبدیل شده است. استفاده از ماشین های مهر و موم فوم به شرکت ها اجازه می دهد تا دو...

مشاهده بیشتر