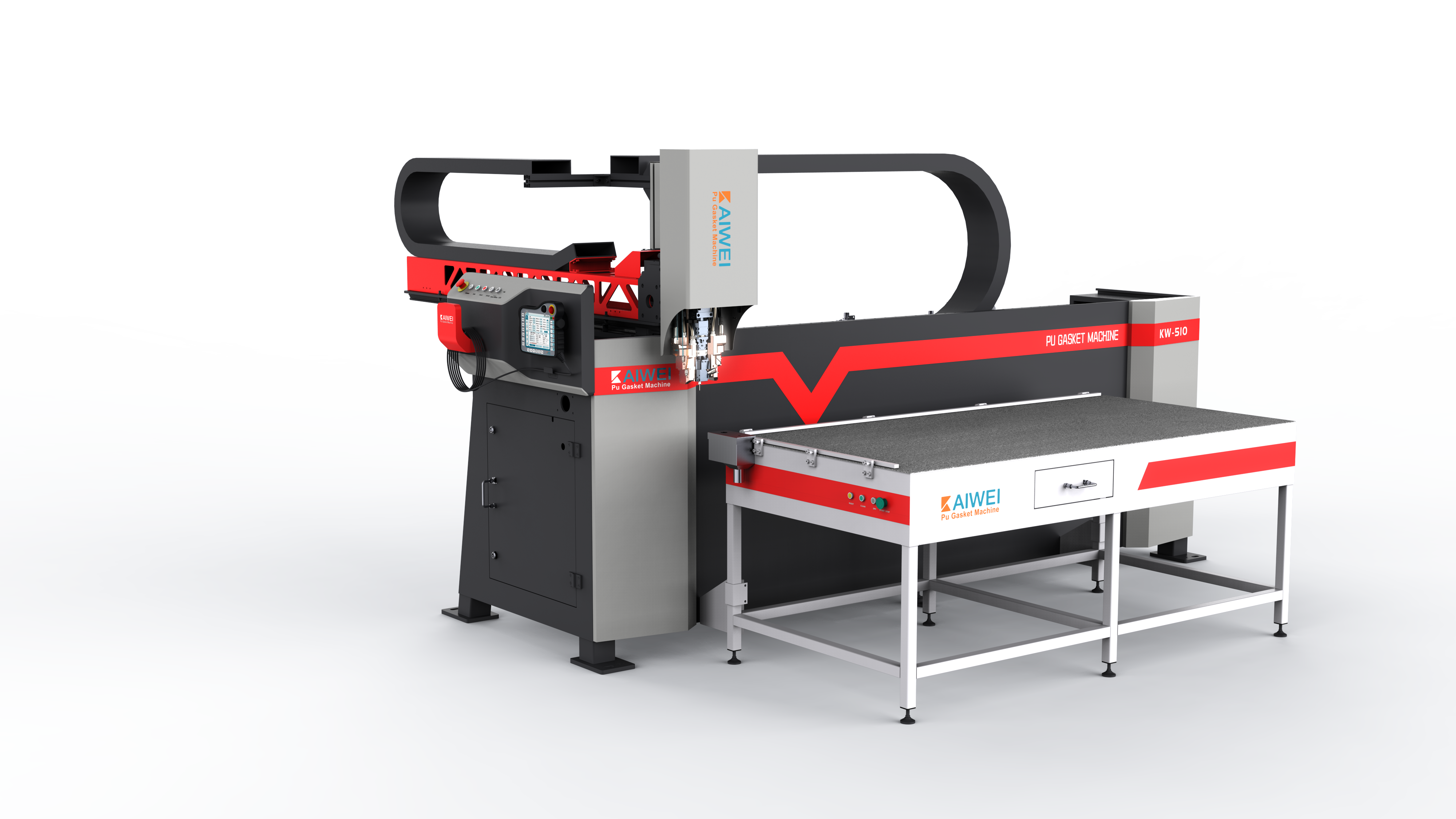

pu seal gluing machine

The PU seal gluing machine represents a cutting-edge solution for industrial sealing applications, specifically engineered to apply polyurethane-based adhesives with exceptional precision and consistency. This sophisticated equipment serves as the backbone of modern manufacturing processes where hermetic sealing is critical for product integrity and performance. The machine operates through an automated system that dispenses, spreads, and cures polyurethane sealants across various substrate materials, ensuring optimal adhesion and long-lasting seal integrity. At its core, the PU seal gluing machine incorporates advanced dispensing technology that controls adhesive flow rates, temperature regulation, and application patterns with remarkable accuracy. The system features programmable logic controllers that enable operators to customize application parameters based on specific material requirements and production specifications. Key technological features include heated adhesive reservoirs that maintain optimal viscosity levels, precision metering pumps that ensure consistent dispensing volumes, and automated mixing chambers that blend multi-component polyurethane formulations in real-time. The machine's versatility extends across numerous industrial sectors, including automotive manufacturing for weatherstrip installation, construction industry applications for structural glazing, electronics assembly for component encapsulation, and aerospace production for critical sealing operations. Modern PU seal gluing machines incorporate touchscreen interfaces that simplify operation while providing comprehensive monitoring capabilities for quality control purposes. These systems often feature integrated vision systems that verify seal placement accuracy and detect potential defects before products advance to subsequent manufacturing stages. The equipment typically includes multiple application heads that can simultaneously process different seal configurations, significantly enhancing production throughput while maintaining consistent quality standards across all output units.