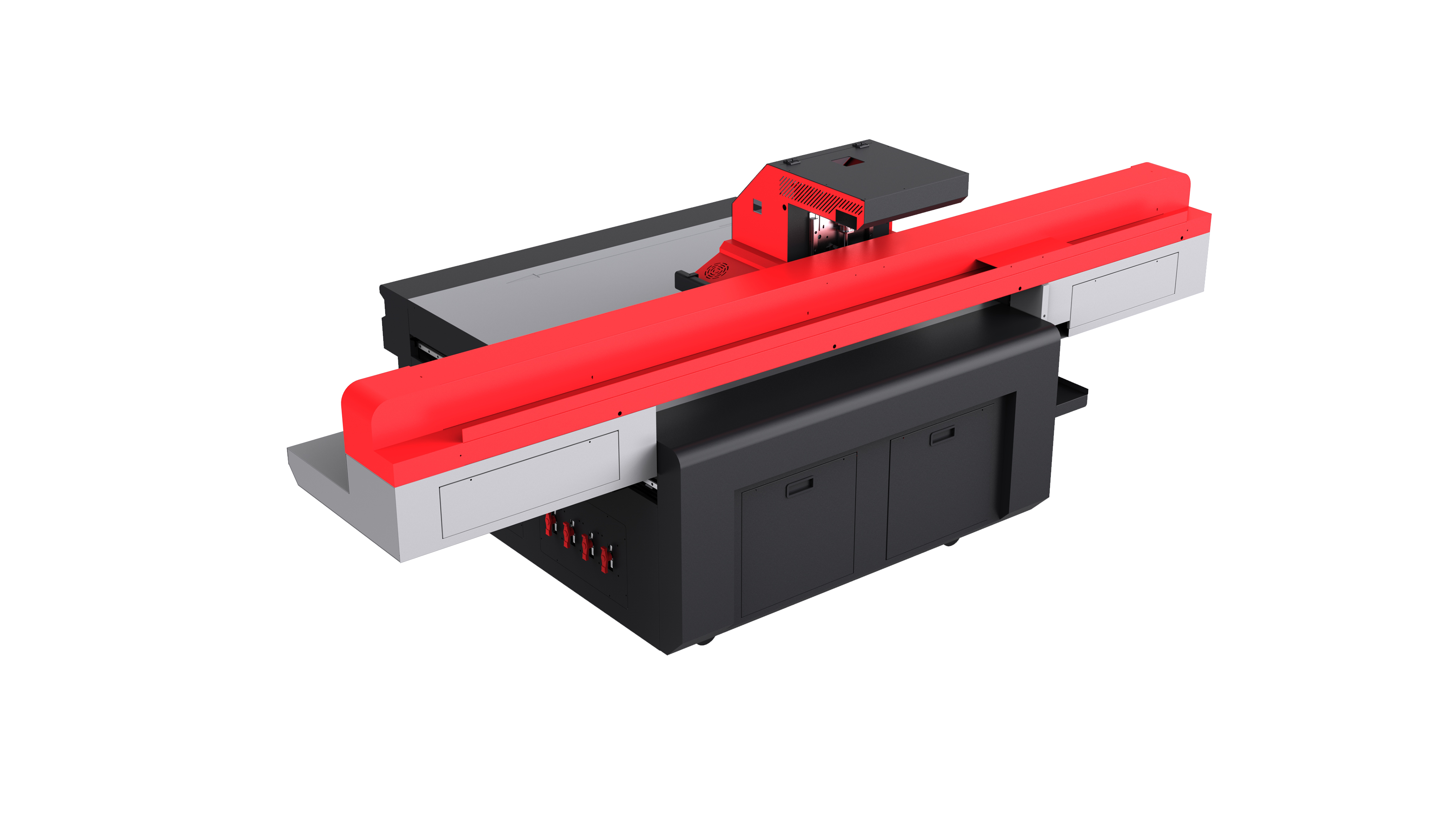

kestävä uv-digitaalitulostin

Kestävä UV-digitaalitulostin edustaa uusinta tulostusteknologiaa, jossa yhdistyvät ultraviolettivalon kuivatus ja tarkka digitaalinen mustesuihkuteknologia saavuttaakseen erinomaisen tulostuslaadun monenlaisilla materiaaleilla. Tämä edistynyt tulostusratkaisu käyttää erikoisia UV-kovettuvia musteita, jotka kuivuvat ja kovettuvat välittömästi altistuessaan UV-valolle, tuottaen voimakkaita, pitkäikäisiä tulosteita, jotka kestävät hämärtyvää, naarmuja ja ympäristövaurioita. Kestävä UV-digitaalitulostin toimii monimutkaisella prosessilla, jossa nestemäiset musteet asetetaan alustalle ja kovetetaan välittömästi voimakkaiden LED- tai elohopea-UV-lamppujen avulla, jolloin tulosteet säilyttävät laadunsa vuosien ajan ilman heikkenemistä. Nämä koneet sisältävät muuttuvan pisaran teknologian, joka mahdollistaa tarkan musteen sijoittamisen, tuottaen teräviä tekstejä, tasaisia sävyjen siirtymiä ja tarkan värinviljelyn. Kestävän UV-digitaalitulostimen monipuolisuus ilmenee sen kyvyssä tulostaa jäykille ja joustaville materiaaleille, kuten lasiin, metalliin, puuhun, akryyliin, tekstiiliin, vinyyliin ja erilaisiin muoveihin ilman erityiskohteita tai esikäsittelyä. Modernit kestävät UV-digitaalitulostinjärjestelmät sisältävät edistyneen tulostuspään teknologian useilla värikonfiguraatioilla, mikä mahdollistaa laajennetut väihtevyydet ja erikoisvaikutukset, kuten valkoisen musteen, läpinäkyvän päällysteen ja teksturoitut pinnat. Näiden tulostimien automatisoidut työnkulku-järjestelmät tekevät tuotantoprosesseista tehokkaampia, vähentävät asennusaikaa ja minimoivat hävikin samalla kun maksimoivat tuotantokapasiteetin. Ympäristönäkökohdat on otettu huomioon ympäristöystävällisillä UV-musteilla, jotka eivät sisällä haihtuvia orgaanisia yhdisteitä eivätkä tuota merkittävää hajua tulostuksen aikana. Kestävän UV-digitaalitulostimen tarkka insinöörituotanto takaa johdonmukaisen rekisteröinnin, tarkan värinsävyn ja luotettavan suorituskyvyn myös pitkissä tuotantokajoissa, mikä tekee siitä olennaisen työkalun yrityksille, jotka tarvitsevat korkealaatuisia, kestäviä tulostettuja materiaaleja sekä sisä- että ulkokäyttöön.