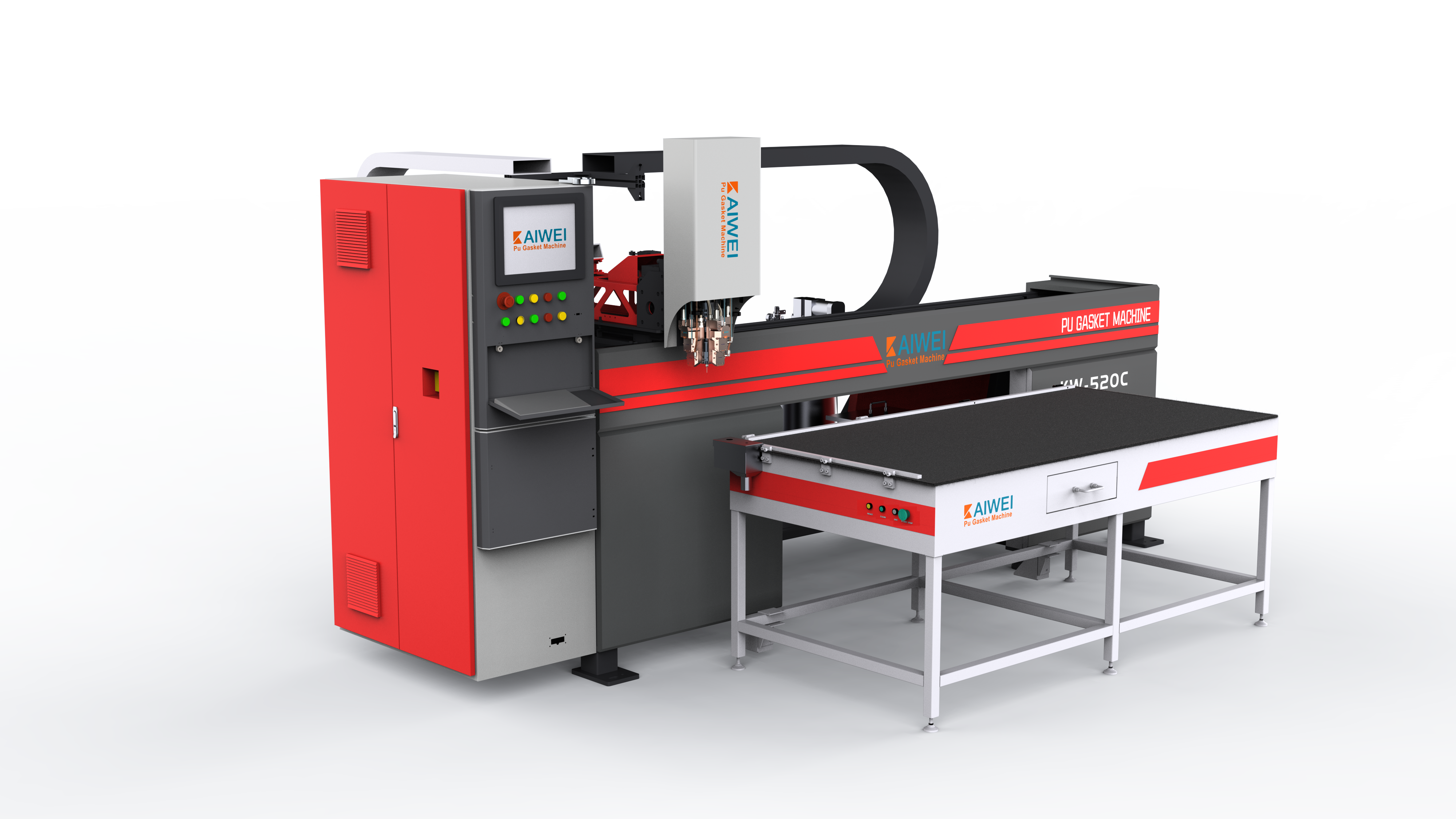

શ્રેષ્ઠ પૂર્ણસ્વતંત્ર ગ્લુ ડિસ્પેન્સર નિર્માતા

એક ઉત્કૃષ્ટ ફુલ-ઓટોમેટિક ગ્લુ ડિસ્પેન્સર નિર્માતા ચોકસાઈયુક્ત એડહેસિવ એપ્લિકેશન ટેકનોલોજીની ટોચ દર્શાવે છે, જે ઘણા ક્ષેત્રોમાં ઔદ્યોગિક બોન્ડિંગ પ્રક્રિયાઓને ક્રાંતિકારી બનાવે તેવા ઉન્નત ઉકેલો પૂરા પાડે છે. આ વિકસિત મશીનો ઉન્નત ઓટોમેશન સિસ્ટમ્સને બુદ્ધિશાળી નિયંત્રણ યંત્રો સાથે એકીકૃત કરે છે, જે ગ્લુ ડિસ્પેન્સિંગની કામગીરીને સુસંગત, ચોકસાઈભર્યું અને કાર્યક્ષમ બનાવે છે. મુખ્ય કાર્યોમાં ચોક્કસ કદનું નિયંત્રણ, પ્રોગ્રામ કરી શકાય તેવા ડિસ્પેન્સિંગ પેટર્ન, રિયલ-ટાઇમ મોનિટરિંગ ક્ષમતાઓ અને હાલની ઉત્પાદન લાઇન્સ સાથે સરળ એકીકરણનો સમાવેશ થાય છે. આધુનિક યુનિટ્સમાં ઉન્નત સર્વો મોટર સિસ્ટમ્સ હોય છે જે એડહેસિવની ચોક્કસ ગોઠવણીમાં અત્યંત ચોકસાઈ સુનિશ્ચિત કરે છે, જ્યારે બુદ્ધિશાળી સેન્સર્સ લાંબા સમય સુધી ચાલતી કામગીરી દરમિયાન વિસ્કોસિટી સ્તરો, તાપમાનમાં ફેરફાર અને પ્રવાહની દરને સતત મોનિટર કરીને ઉત્તમ કામગીરીના ધોરણો જાળવે છે. આ ટેકનોલોજીકલ આર્કિટેક્ચરમાં સ્ટેટ-ઓફ-ધ-આર્ટ માઇક્રોપ્રોસેસર નિયંત્રણોનો સમાવેશ થાય છે જે ઓપરેટર્સને ચોક્કસ એપ્લિકેશન જરૂરિયાતો મુજબ ડિસ્પેન્સિંગ પરિમાણોને કસ્ટમાઇઝ કરવાની મંજૂરી આપે છે, જેમાં ગતિ સેટિંગ્સ, દબાણ નિયંત્રણ અને પેટર્ન પ્રોગ્રામિંગ ક્ષમતાઓને એડજસ્ટ કરવાનો સમાવેશ થાય છે. આ સિસ્ટમ્સ ઓછી વિસ્કોસિટીવાળા સાયનોએક્રિલેટ્સથી લઈને ઊંચી વિસ્કોસિટીવાળા સ્ટ્રક્ચરલ એડહેસિવ્સ સુધીના વિવિધ પ્રકારના એડહેસિવ્સને આધાર આપે છે, જે વિવિધ ઔદ્યોગિક જરૂરિયાતોને પૂર્ણ કરે છે. મુખ્ય એપ્લિકેશન્સમાં ઇલેક્ટ્રોનિક્સ ઉત્પાદન, ઓટોમોટિવ એસેમ્બલી, મેડિકલ ઉપકરણ ઉત્પાદન, પેકેજિંગ ઓપરેશન્સ અને ગ્રાહક સામાન ઉત્પાદનનો સમાવેશ થાય છે, જ્યાં ચોક્કસ એડહેસિવ ગોઠવણી ઉત્પાદનની ગુણવત્તા અને વિશ્વસનીયતાને સીધી અસર કરે છે. ઉત્કૃષ્ટ ફુલ-ઓટોમેટિક ગ્લુ ડિસ્પેન્સર નિર્માતા સરળ ઈન્ટરફેસ સાથે સાધનોની ડિઝાઇન કરે છે જે તાલીમની જરૂરિયાતોને લઘુતમ કરે છે અને કામગીરીની કાર્યક્ષમતાને મહત્તમ કરે છે. ઉન્નત સુવિધાઓમાં ઓટોમેટેડ સફાઈ ચક્રો, આગાહી જાળવણી ચેતવણીઓ અને ગુણવત્તા નિયંત્રણ ડોક્યુમેન્ટેશનને સુગમ બનાવતી વિગતવાર ડેટા લોગિંગ ક્ષમતાઓનો સમાવેશ થાય છે. આ મશીનો મોડ્યુલર ડિઝાઇન દ્વારા અત્યંત લવચીકતા દર્શાવે છે જે વિવિધ ઉત્પાદન માત્રાઓ અને વર્કસ્પેસ ગોઠવણીઓને આધાર આપે છે, જેના કારણે તે મોટા પ્રમાણમાં ઉત્પાદન વાતાવરણ અને ચોક્કસ એડહેસિવ એપ્લિકેશન પ્રોટોકોલ્સની જરૂરિયાત ધરાવતી વિશિષ્ટ ઉત્પાદન સુવિધાઓ માટે યોગ્ય બને છે.