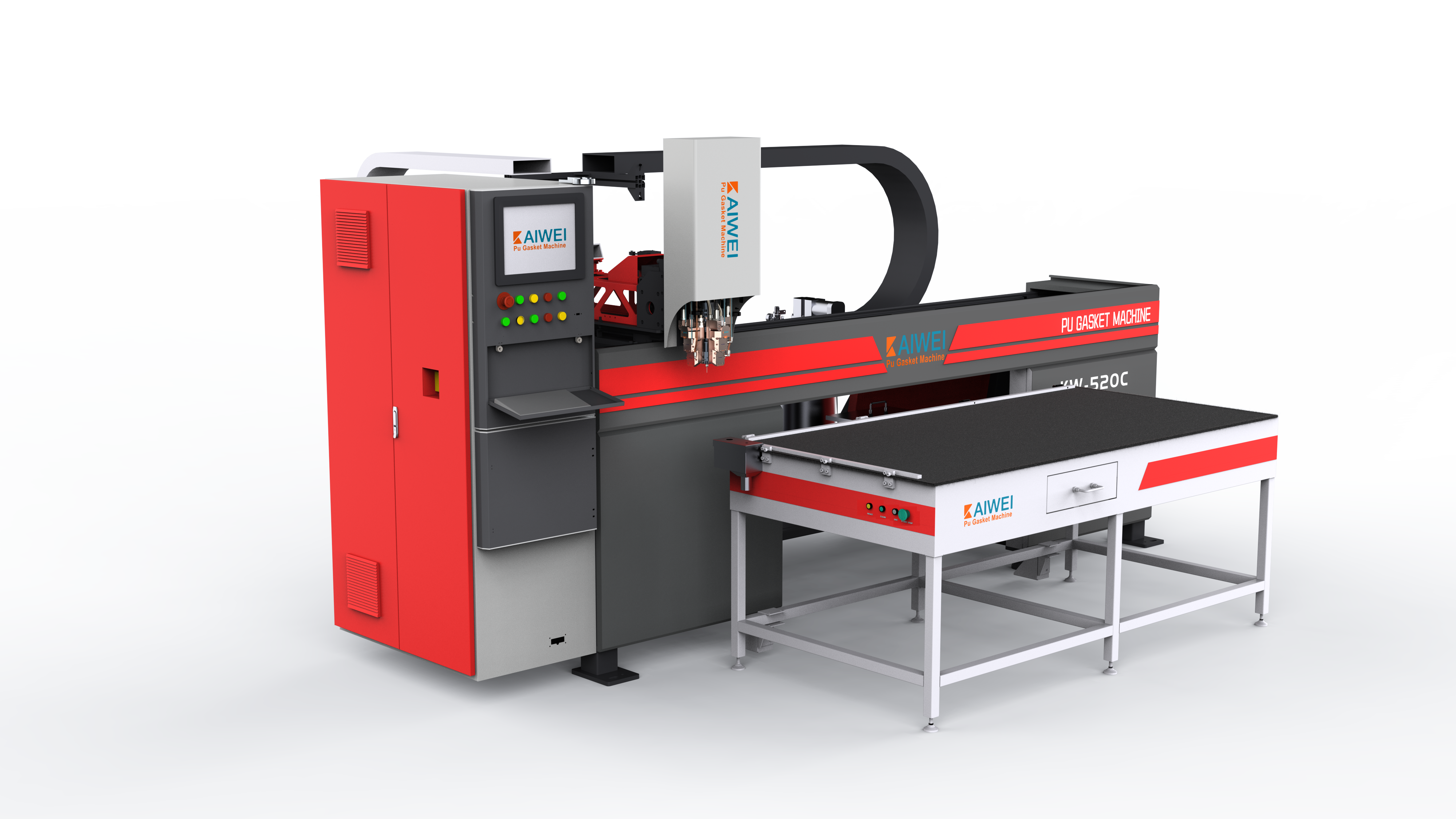

excellent fullautomatic glue dispenser manufacturer

An excellent full-automatic glue dispenser manufacturer represents the pinnacle of precision adhesive application technology, delivering advanced solutions that revolutionize industrial bonding processes across multiple sectors. These sophisticated machines integrate cutting-edge automation systems with intelligent control mechanisms, ensuring consistent, accurate, and efficient glue dispensing operations. The primary functions encompass precise volume control, programmable dispensing patterns, real-time monitoring capabilities, and seamless integration with existing production lines. Modern units feature advanced servo motor systems that guarantee exceptional accuracy in adhesive placement, while intelligent sensors continuously monitor viscosity levels, temperature variations, and flow rates to maintain optimal performance standards throughout extended operational periods. The technological architecture incorporates state-of-the-art microprocessor controls that enable operators to customize dispensing parameters according to specific application requirements, including adjustable speed settings, pressure regulation, and pattern programming capabilities. These systems support various adhesive types, from low-viscosity cyanoacrylates to high-viscosity structural adhesives, accommodating diverse industrial needs. Key applications span electronics manufacturing, automotive assembly, medical device production, packaging operations, and consumer goods manufacturing, where precise adhesive placement directly impacts product quality and reliability. The excellent full-automatic glue dispenser manufacturer designs equipment with user-friendly interfaces that minimize training requirements while maximizing operational efficiency. Advanced features include automated cleaning cycles, predictive maintenance alerts, and comprehensive data logging capabilities that facilitate quality control documentation. These machines demonstrate exceptional versatility through modular designs that accommodate different production volumes and workspace configurations, making them suitable for both high-volume manufacturing environments and specialized production facilities requiring precise adhesive application protocols.