પ્યુ ડિસ્પેન્સિંગ મશીન કિમત

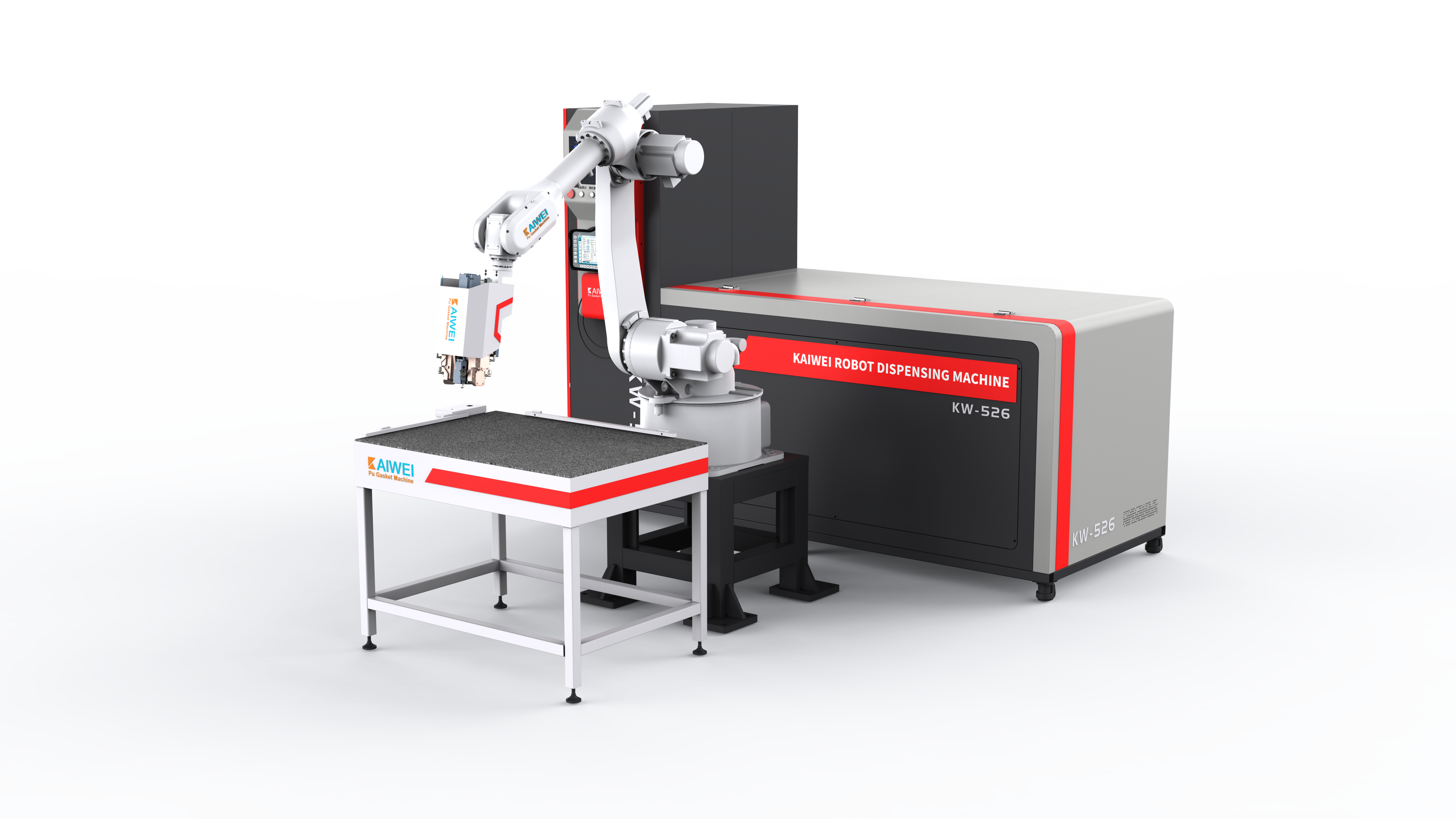

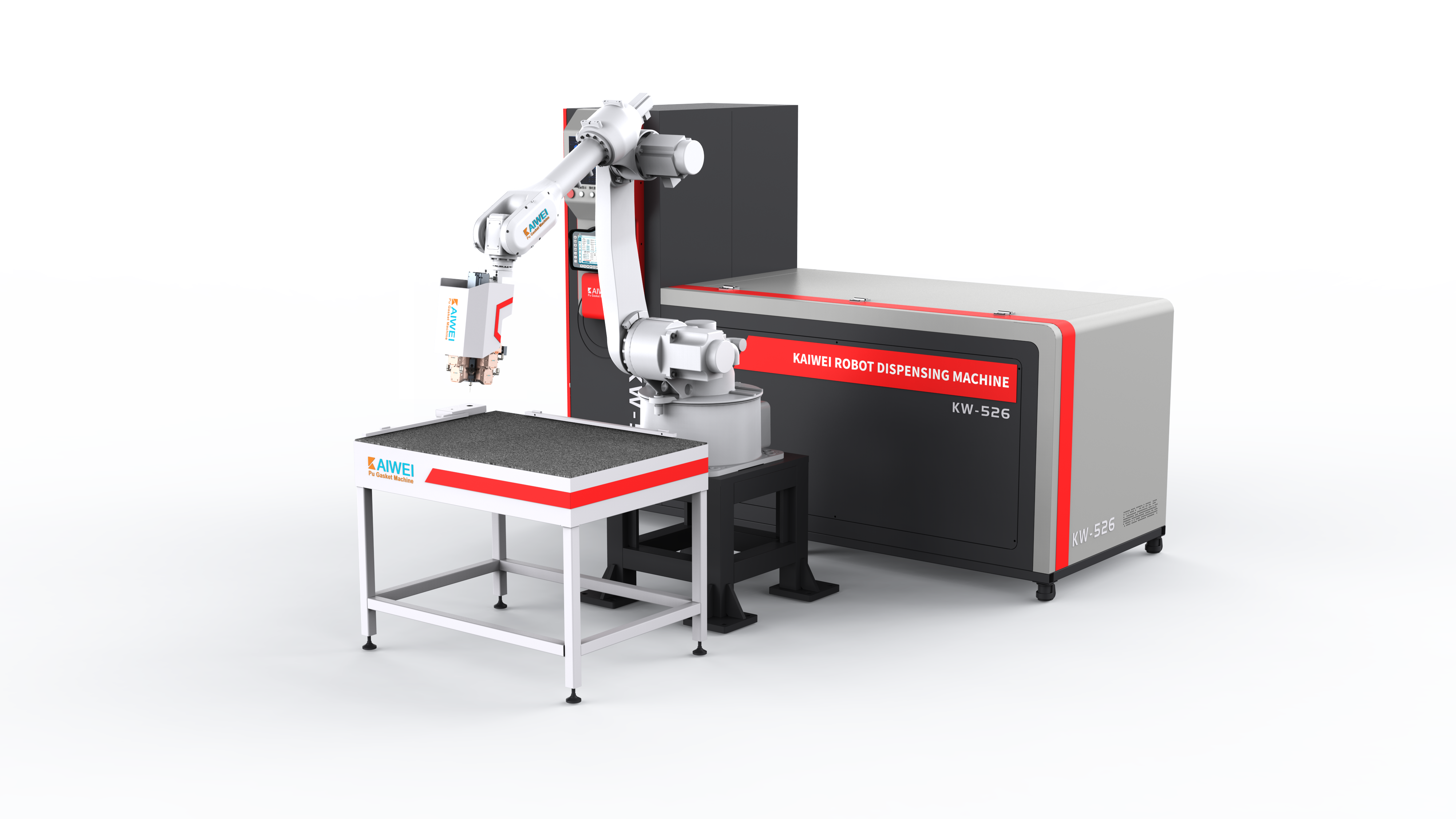

પોલિયુરેથેન ડિસ્પેન્સિંગ મશીનની કિંમત કાર્યક્ષમ પોલિયુરેથેન એપ્લિકેશન ઉકેલો શોધતા ઉત્પાદકો માટે એક મહત્વપૂર્ણ રોકાણ પરિબળ છે. આ પરિષ્કૃત સિસ્ટમ્સને વિવિધ ઔદ્યોગિક એપ્લિકેશન્સમાં પોલિયુરેથેન સામગ્રીનું ચોકસાઈપૂર્વક, નિયંત્રિત ડિસ્પેન્સિંગ પૂરું પાડવા માટે ડિઝાઇન કરવામાં આવે છે. પીયુ ડિસ્પેન્સિંગ મશીનના મૂળભૂત કાર્યોમાં સામગ્રીનું ચોકસાઈપૂર્વક મિશ્રણ, તાપમાન નિયંત્રણ, દબાણ નિયંત્રણ અને સુસંગત પ્રવાહ દર નિયંત્રણનો સમાવેશ થાય છે. આધુનિક યુનિટ્સમાં ઉન્નત માપન સિસ્ટમ્સ હોય છે જે ઘટકોના આદર્શ ગુણોત્તરની ખાતરી કરે છે, સામાન્ય રીતે A અને B ઘટકોના મિશ્રણ ગુણોત્તરને અત્યંત ચોકસાઈપૂર્વક જાળવે છે. તાપમાન નિયંત્રણ ક્ષમતાઓ વાતાવરણીયથી લઈને ઊંચા પ્રક્રિયા તાપમાન સુધીની હોય છે, જે વિવિધ પીયુ ફોર્મ્યુલેશન્સ અને શ્યાનતાને અનુરૂપ હોય છે. ટેકનોલોજીકલ આર્કિટેક્ચરમાં સર્વો-ડ્રિવન પંપ્સ, ડિજિટલ પ્રવાહ મીટર્સ અને કમ્પ્યુટરાઇઝ્ડ કંટ્રોલ ઇન્ટરફેસનો સમાવેશ થાય છે જે ઑપરેટર્સને જટિલ ડિસ્પેન્સિંગ પેટર્ન્સ પ્રોગ્રામ કરવાની મંજૂરી આપે છે. ઉન્નત મોડેલ્સમાં રિયલ-ટાઇમ મોનિટરિંગ સિસ્ટમ્સનો સમાવેશ થાય છે જે ડિસ્પેન્સિંગ પ્રક્રિયા દરમિયાન સામગ્રીની વપરાશ, દબાણમાં ફેરફાર અને તાપમાનમાં ચઢ-ઉતરને ટ્રેક કરે છે. આ મશીન્સ ઓટોમોટિવ ગેસ્કેટ ઉત્પાદન, ઇલેક્ટ્રોનિક ઘટકોનું એન્કેપ્સ્યુલેશન, કન્સ્ટ્રક્શન સીલન્ટ ઉત્પાદન અને ફૂટવેર સોલ એટેચમેન્ટ પ્રક્રિયાઓ સહિતની એપ્લિકેશન્સમાં ઉત્કૃષ્ટતા ધરાવે છે. એરોસ્પેસ, મેરિન અને નવીકરણીય ઊર્જા જેવા ઔદ્યોગિક ક્ષેત્રો આ સિસ્ટમ્સનો ઉપયોગ સ્ટ્રક્ચરલ બોન્ડિંગ અને વોટરપ્રૂફિંગ એપ્લિકેશન્સ માટે કરે છે. પીયુ ડિસ્પેન્સિંગ મશીનની કિંમત ક્ષમતાની સ્પષ્ટતાઓ, ઓટોમેશન સ્તરો અને ચોકસાઈની જરૂરિયાતોના આધારે નોંધપાત્ર રીતે બદલાય છે. એન્ટ્રી-લેવલ મેન્યુઅલ સિસ્ટમ્સ નાની ઓપરેશન્સ માટે મૂળભૂત કાર્યક્ષમતા પૂરી પાડે છે, જ્યારે સંપૂર્ણપણે ઓટોમેટેડ ઔદ્યોગિક યુનિટ્સ ઇન્ટિગ્રેટેડ ક્વોલિટી કંટ્રોલ સુવિધાઓ સાથે ઉચ્ચ-આઉટપુટ ક્ષમતા પૂરી પાડે છે. સામગ્રી હેન્ડલિંગ ક્ષમતાઓ નાના બેચ પ્રોસેસિંગથી લઈને ચાલુ ઉત્પાદન વાતાવરણ સુધીની હોય છે, કેટલીક સિસ્ટમ્સ એક સાથે બહુવિધ સામગ્રી પ્રકારોને સમાવવાની ક્ષમતા ધરાવે છે. ગુણવત્તાયુક્ત પીયુ ડિસ્પેન્સિંગ સિસ્ટમમાં રોકાણ સીધી રીતે ઉત્પાદન કાર્યક્ષમતા, વ્યર્થતામાં ઘટાડો અને ઉત્પાદન સુસંગતતાને અસર કરે છે, જેથી પીયુ ડિસ્પેન્સિંગ મશીનની કિંમતનું મૂલ્યાંકન સંચાલન સફળતા માટે આવશ્યક બને છે.