pu dispensing machine price

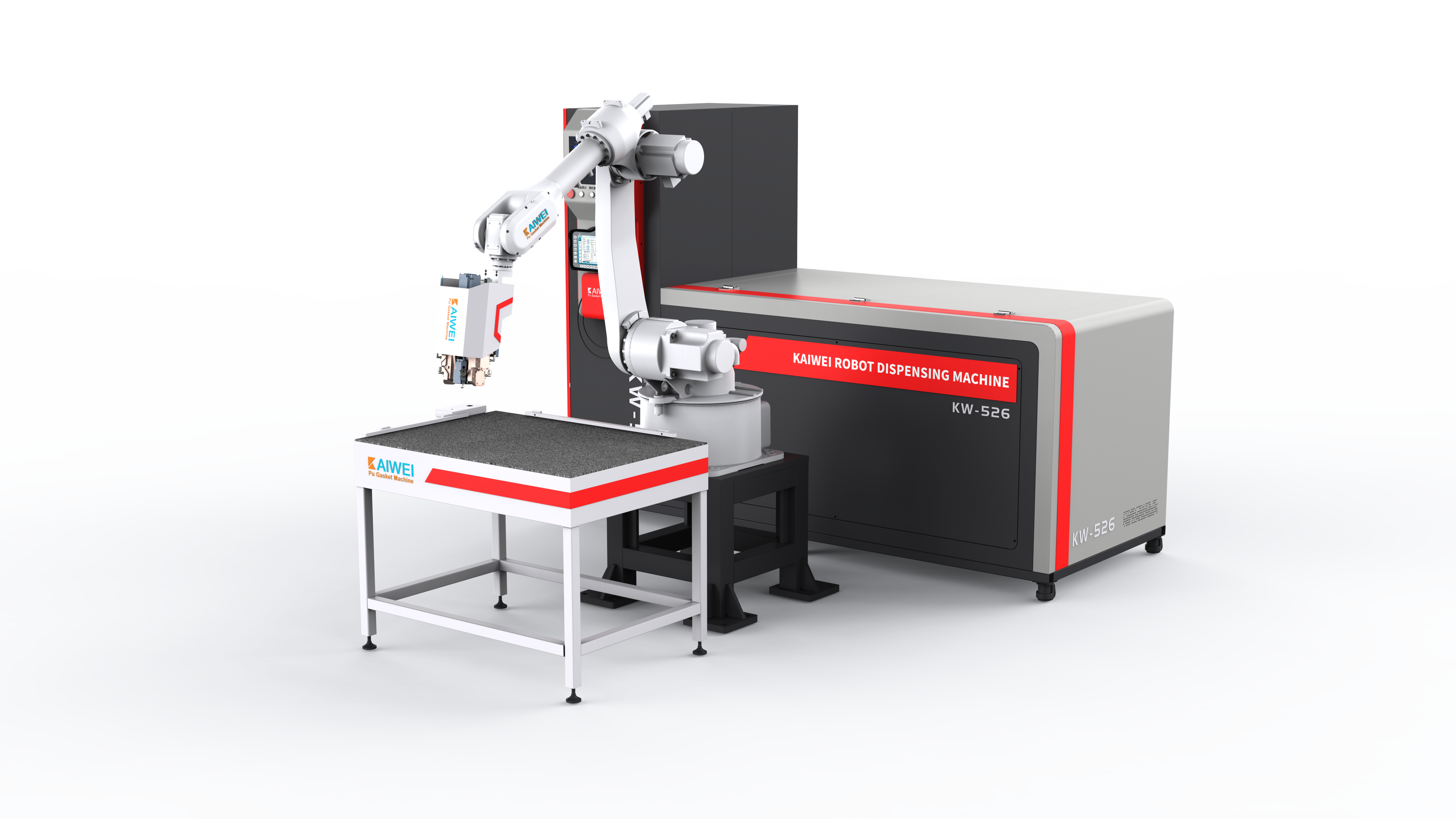

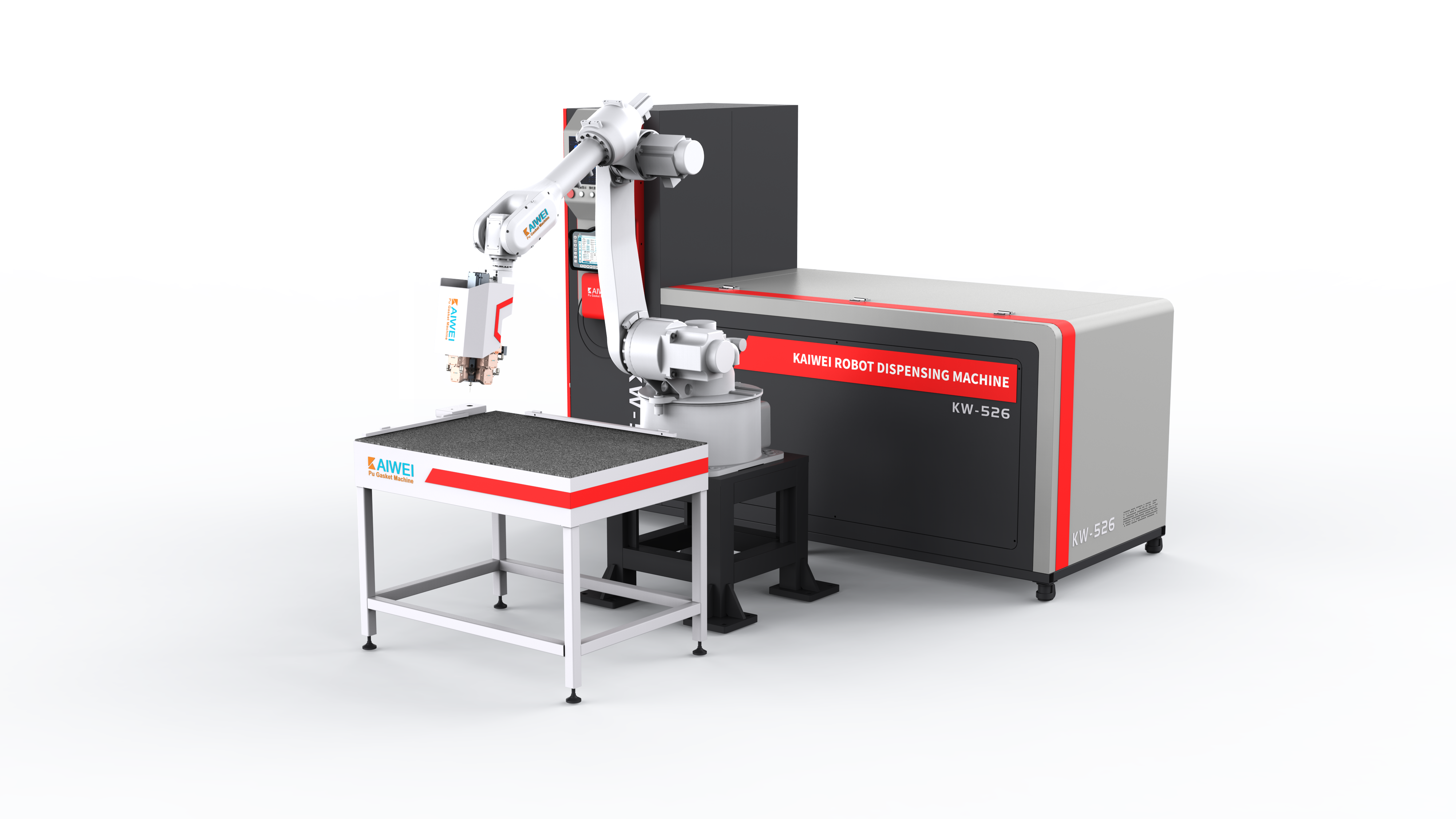

The pu dispensing machine price represents a critical investment factor for manufacturers seeking efficient polyurethane application solutions. These sophisticated systems are engineered to deliver precise, controlled dispensing of polyurethane materials across diverse industrial applications. The fundamental functions of a PU dispensing machine encompass accurate material mixing, temperature regulation, pressure control, and consistent flow rate management. Modern units feature advanced metering systems that ensure optimal component ratios, typically maintaining A and B component mixing ratios with exceptional accuracy. Temperature control capabilities range from ambient to elevated processing temperatures, accommodating various PU formulations and viscosities. The technological architecture incorporates servo-driven pumps, digital flow meters, and computerized control interfaces that enable operators to program complex dispensing patterns. Advanced models integrate real-time monitoring systems that track material consumption, pressure variations, and temperature fluctuations throughout the dispensing process. These machines excel in applications spanning automotive gasket manufacturing, electronic component encapsulation, construction sealant production, and footwear sole attachment processes. Industrial sectors including aerospace, marine, and renewable energy utilize these systems for structural bonding and waterproofing applications. The pu dispensing machine price varies significantly based on capacity specifications, automation levels, and precision requirements. Entry-level manual systems offer basic functionality for smaller operations, while fully automated industrial units provide high-throughput capabilities with integrated quality control features. Material handling capabilities range from small batch processing to continuous production environments, with some systems accommodating multiple material types simultaneously. The investment in a quality PU dispensing system directly impacts production efficiency, waste reduction, and product consistency, making the pu dispensing machine price evaluation essential for operational success.