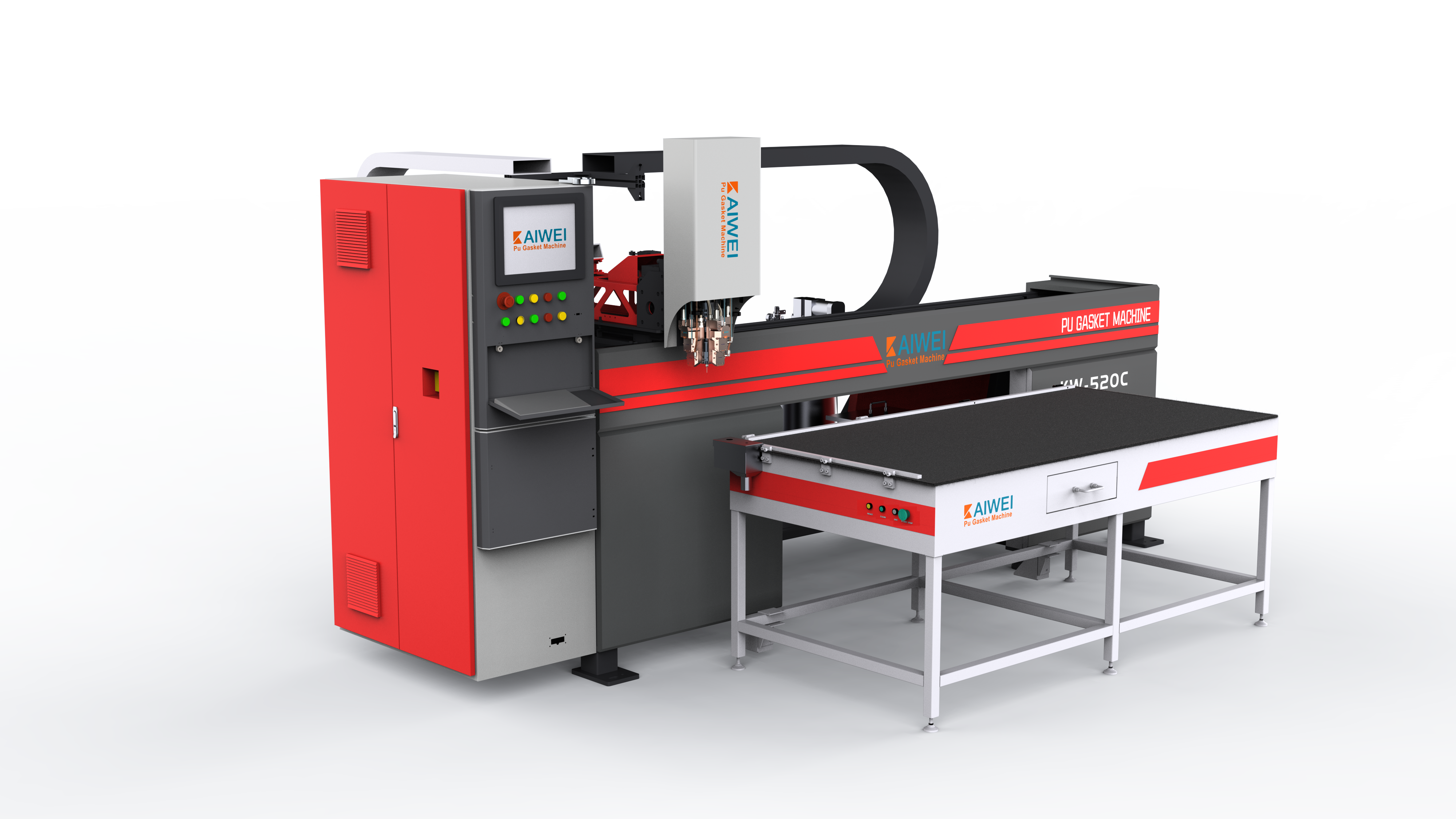

लोकप्रिय पूर्ण स्वचालित ग्लू डिस्पेनसर निर्माता

आधुनिक विनिर्माण क्षेत्र में चिपकाने की प्रक्रियाओं में सटीकता, दक्षता और विश्वसनीयता की मांग होती है। एक लोकप्रिय पूर्ण-स्वचालित ग्लू डिस्पेंसर निर्माता इस तकनीकी क्रांति के अग्रिम मोर्चे पर खड़ा है, जो उद्योगों द्वारा बॉण्डिंग अनुप्रयोगों के दृष्टिकोण को बदलने वाले अत्याधुनिक समाधान प्रदान करता है। ये परिष्कृत प्रणालियाँ स्वचालित डिस्पेंसिंग तकनीक की पराकाष्ठा को दर्शाती हैं, जो उन्नत इंजीनियरिंग को उपयोगकर्ता के अनुकूल संचालन के साथ जोड़कर विविध औद्योगिक आवश्यकताओं को पूरा करती हैं। इन स्वचालित प्रणालियों के मुख्य कार्यों में सटीक आयतन नियंत्रण, सुसंगत आवेदन पैटर्न और मौजूदा उत्पादन लाइनों के साथ चिकनी एकीकरण शामिल है। ये डिस्पेंसर निम्न-श्यानता वाले तरलों से लेकर उच्च-श्यानता वाले पेस्ट तक चिपकाने वाली सामग्री की ठीक-ठीक मात्रा को वितरित करने में उत्कृष्ट हैं, जिससे बॉण्ड की ताकत अधिकतम रहती है और अपव्यय न्यूनतम होता है। इनमें उन्नत सर्वो मोटर्स, प्रोग्रामेबल लॉजिक कंट्रोलर्स और सहज टचस्क्रीन इंटरफेस जैसी तकनीकी विशेषताएँ शामिल हैं, जो ऑपरेटरों को जटिल डिस्पेंसिंग पैटर्न को अद्भुत आसानी के साथ कॉन्फ़िगर करने की अनुमति देते हैं। उन्नत दबाव नियमन प्रणाली स्थिर प्रवाह दर बनाए रखती है, जबकि वास्तविक समय में निगरानी की क्षमता डिस्पेंसिंग मापदंडों पर तुरंत प्रतिक्रिया प्रदान करती है। तापमान नियंत्रण मॉड्यूल यह सुनिश्चित करते हैं कि आवेदन प्रक्रिया भर चिपकाने वाली सामग्री इष्टतम कार्यशील स्थिति में बनी रहे। इनके अनुप्रयोग इलेक्ट्रॉनिक्स निर्माण, ऑटोमोटिव असेंबली, चिकित्सा उपकरण उत्पादन, एयरोस्पेस घटकों और उपभोक्ता वस्तुओं के निर्माण सहित कई उद्योगों में फैले हुए हैं। इलेक्ट्रॉनिक्स में, ये प्रणालियाँ थर्मल इंटरफेस सामग्री, कॉन्फॉर्मल कोटिंग्स और संरचनात्मक चिपकने वालों को माइक्रॉन-स्तर की सटीकता के साथ लगाती हैं। ऑटोमोटिव अनुप्रयोगों में गैस्केट सीलिंग, घटक बॉण्डिंग और वेदरस्ट्रिप अटैचमेंट शामिल हैं। चिकित्सा उपकरण निर्माता महत्वपूर्ण घटकों में जैव-अनुकूल चिपकने वाले लगाने के लिए इन प्रणालियों पर निर्भर रहते हैं। इस बहुमुखी प्रकृति का विस्तार पैकेजिंग उद्योगों तक है, जहाँ ये डिस्पेंसर लेबल, सील और सुरक्षात्मक कोटिंग लगाते हैं। गुणवत्ता आश्वासन विशेषताओं में दृष्टि प्रणाली शामिल है जो उचित चिपकने वाले स्थान को सत्यापित करती है, स्वचालित कैलिब्रेशन रूटीन जो लंबी अवधि तक सटीकता बनाए रखते हैं, और व्यापक डेटा लॉगिंग क्षमता जो पारदर्शिता आवश्यकताओं का समर्थन करती है। एकीकरण क्षमता निर्माण निष्पादन प्रणालियों के साथ चिकनी संचार की अनुमति देती है, जो वास्तविक समय में उत्पादन निगरानी और गुणवत्ता नियंत्रण को सक्षम करती है।