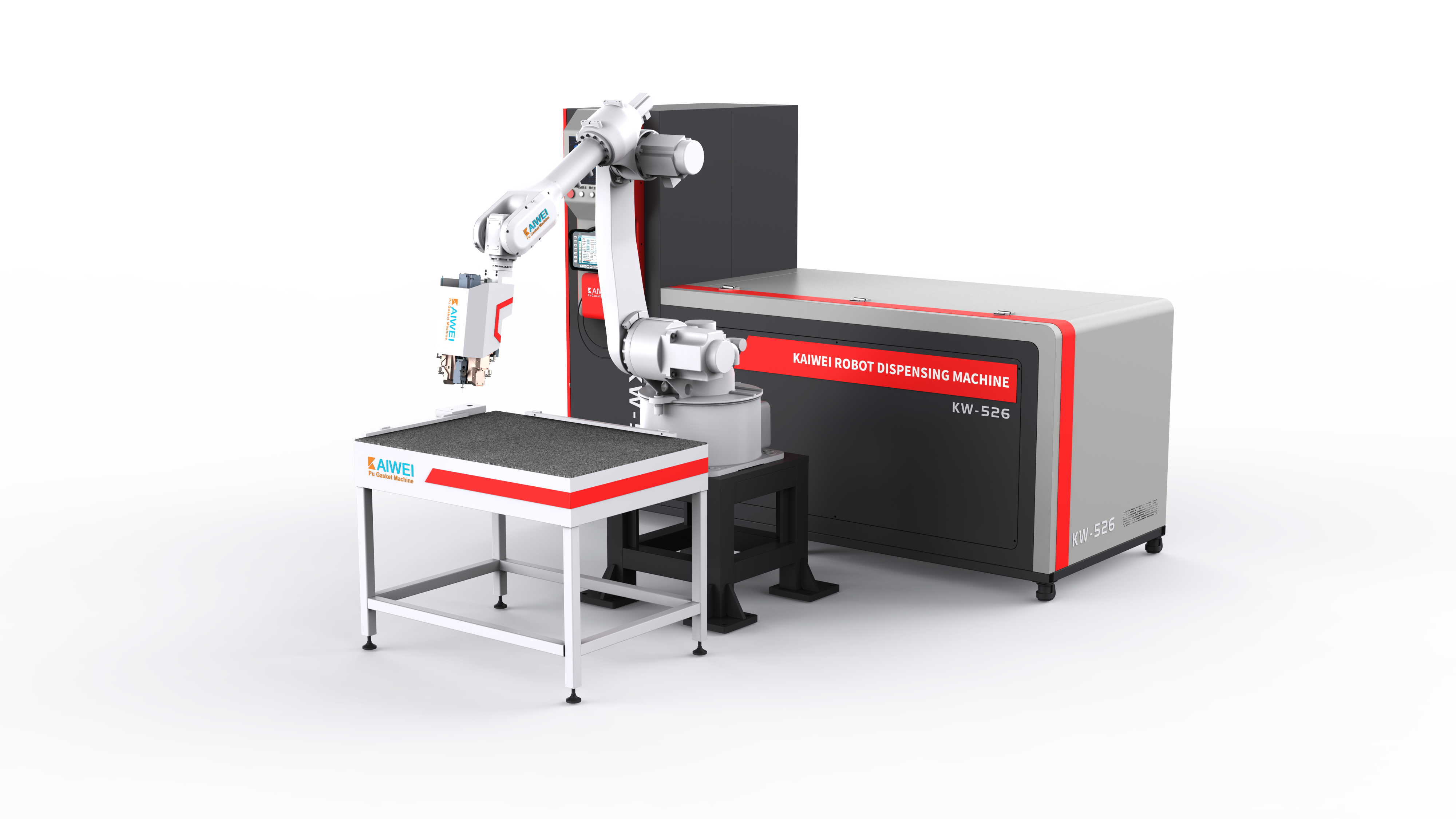

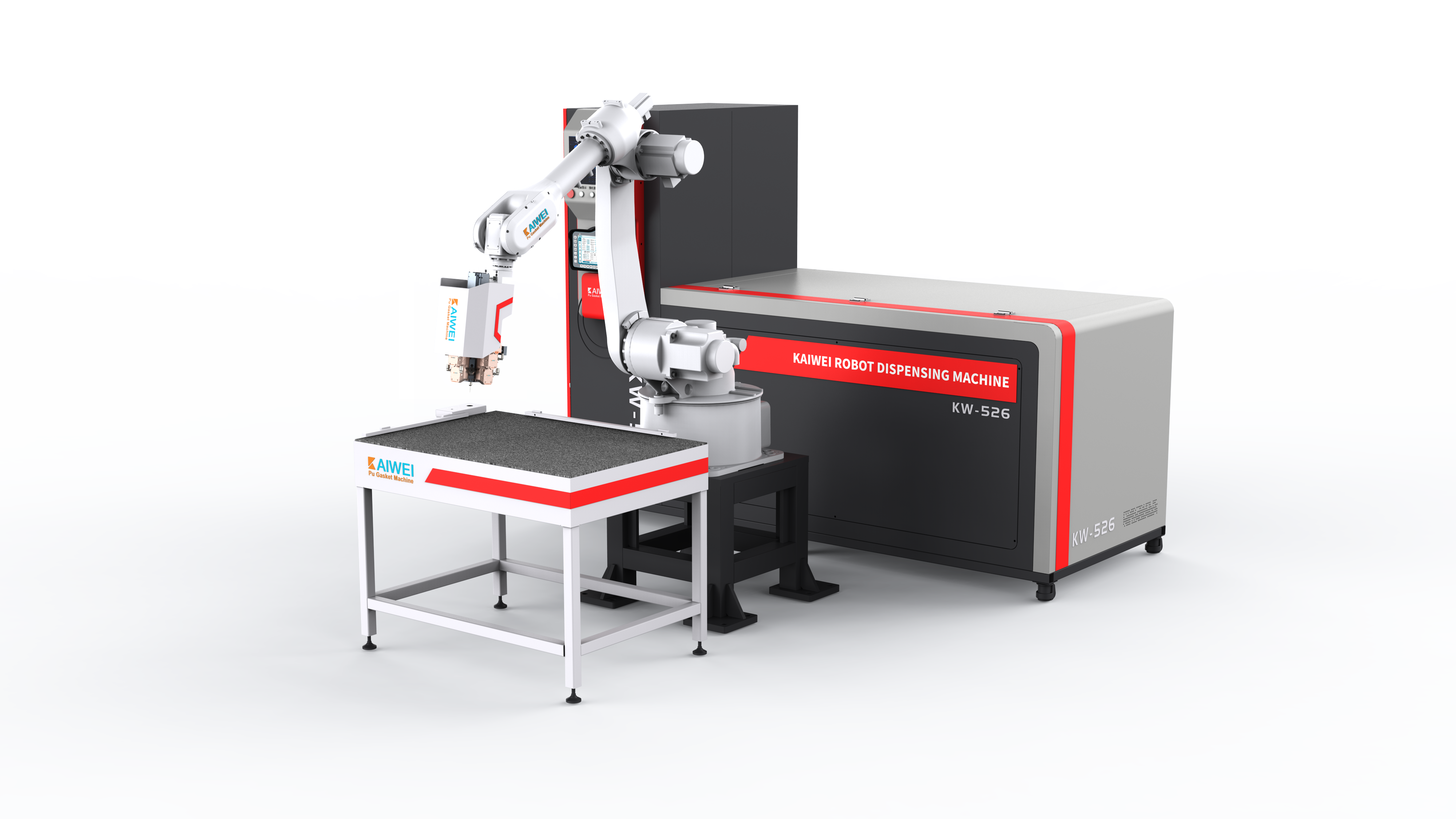

pU пішімдік машина құрылғы жасаушылар

Полиуретан түрінде кебіту машинасын жасаушылар әртүрлі салаларда жоғары сапалы көбік өнімдерін жасау үшін арналған күрделі техникаларды шығаруда маңызды рөл атқаратын өнеркәсіптік жабдық өндірісінің маңызды бөлігі болып табылады. Бұл полиуретан кебіту машиналарын жасаушы компаниялар дәлдікпен химиялық заттарды араластыру, температураны бақылау және автоматты түрде беру мүмкіндіктерін біріктіретін, сапалы полиуретан көбік материалдарын өндіруге мүмкіндік беретін алдыңғы қатарлы жүйелерді әзірлейді. Полиуретан кебіту машиналарын жасаушылардың негізгі функциясы — полифол мен изоцианат компоненттерін, сонымен қатар катализаторлар мен қоспаларды дәл араластырып, белгілі тығыздық пен ұяшықты құрылым сипаттамалары бар ұлғаятын көбік материалдарын алу болып табылады. Қазіргі заманның полиуретан кебіту машиналарын жасаушы компаниялары өндірістің әрбір партиясы бойынша қайталанатын нәтижелерге қол жеткізуге мүмкіндік беретін компьютерлік басқару жүйелерін, нақты уақытта бақылау мүмкіндіктерін және бағдарламаланатын рецептілерді басқару сияқты инновациялық технологиялық ерекшеліктерді енгізеді. Бұл машиналарда, әдетте, химиялық заттардың оптимальды қатынасын кебіту процесінің барлық кезеңінде сақтайтын жоғары қысымды өлшеу сорғылары, қыздырылатын араластыру басы және дәл ағын басқару құрылғылары болады. Жетекші полиуретан кебіту машиналарын жасаушы компаниялардың температураны реттеу жүйелері компоненттердің температурасын қатаң параметрлерде ұстайды, бұл ерте реакциялардың болуын болдырмаумен қатар, көбіктің дұрыс ұлғаюы мен кебу сипаттамаларын қамтамасыз етеді. Бұл жабдықтар автомобиль отырғыштары мен ішкі бөлшектері, жиһаздардың төсеніштері, құрылыстағы жылу оқшаулау панельдері, қаптама материалдары және арнайы өнеркәсіптік қолданыстар сияқты көптеген салаларда қолданылады. Көптеген полиуретан кебіту машиналарын жасаушылар өндірістің нақты талаптарына сәйкес келетін, прототиптік үлгілерді жасауға арналған кіші көлемді қондырғылардан бастап, тәулігіне мыңдаған бөлшектерді шығара алатын жоғары көлемді өндіріс желілеріне дейінгі ыңғайлануы мүмкін конфигурацияларды ұсынады. Алдыңғы қатарлы модельдерге тазалаудың автоматтандырылған циклдері, материалдарды қайта айналдыру жүйелері және қалдықтарды минималдандырып, әрі өнімділікті максималдандыратын интеграцияланған сапа бақылау шаралары енгізілген. Қазіргі заманның полиуретан кебіту машиналарын жасаушы компанияларының технологиялық күрделілігі қолданушыға ыңғайлы интерфейстерге, алыс қашықтықтан бақылау мүмкіндіктеріне және әртүрлі өндірістік орталарда жұмыстың тоқтап қалуын азайтып, операциялық өнімділікті тиімді пайдалануға мүмкіндік беретін болжамды техникалық қызмет көрсету сипаттамаларына дейін кеңейеді.