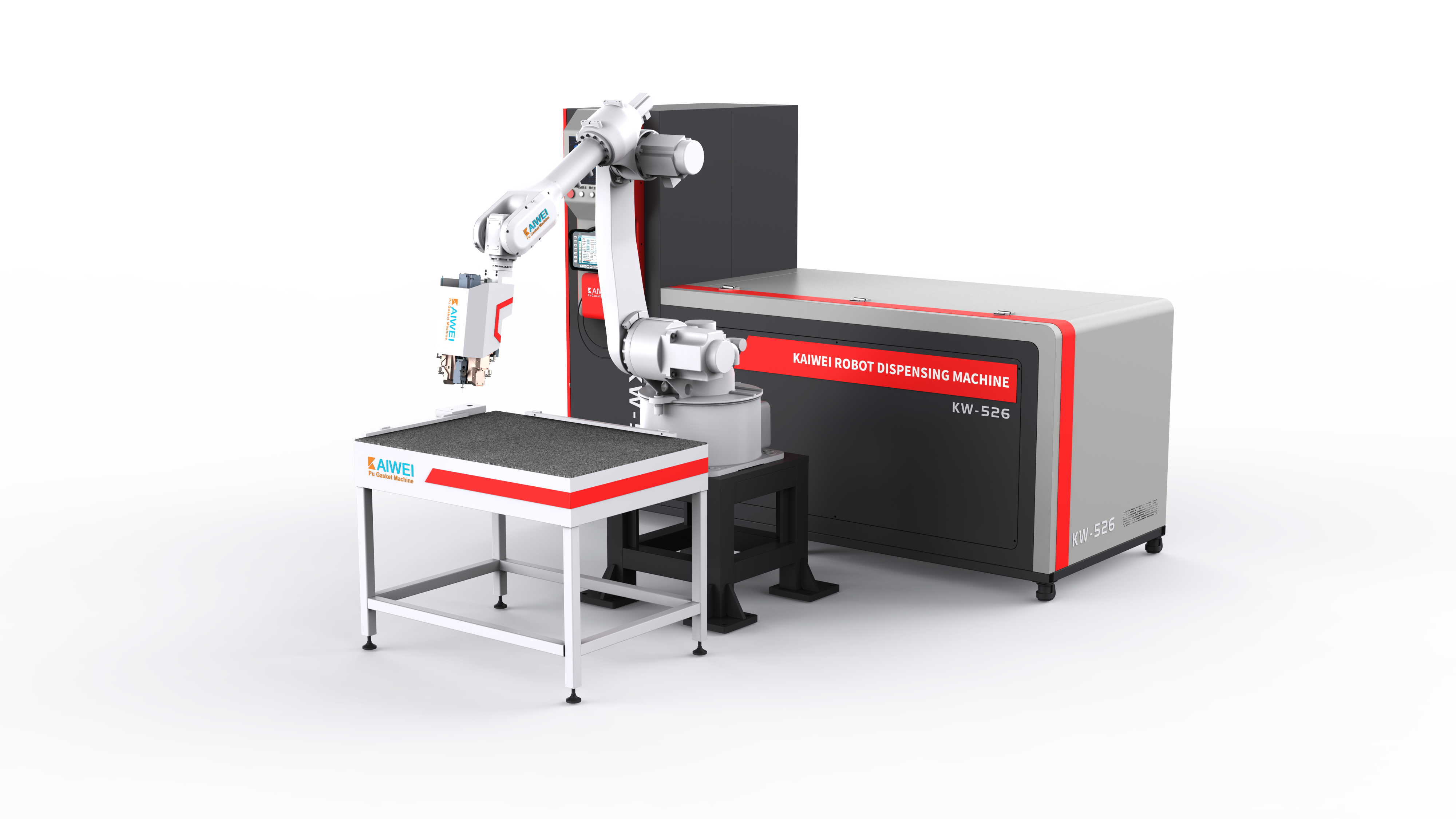

производители на машини за ПУ пенообразувач

Производителите на машина за пенење полиуретан претставуваат клучен сегмент во производството на индустријска опрема, специјализирани за развој на софистицирана машинерија наменета за создавање висококвалитетни пенести производи во повеќе индустрии. Овие производители развивале напредни системи кои комбинираат прецизно мешање на хемикалии, контрола на температурата и автоматско дозирање за производство на постојани полиуретански пенести материјали. Основната функција на опремата од производителите на машина за пенење полиуретан е прецизно мешање на полиол и изоцијанат компоненти, заедно со катализатори и адитиви, за да се создадат пенести материјали со специфична густина и структура на ќелиите. Современите производители на машина за пенење полиуретан вклучуваат револуционерни технолошки карактеристики како што се компјутеризирани системи за контрола, можност за мониторинг во реално време и програмабилно управување со рецепти, што гарантира повторливи резултати низ сериите производство. Овие машини обично имаат пумпи за дозирање под висок притисок, загревани глави за мешање и прецизни регулатори на проток кои ги одржуваат оптималните односи на хемикалии во текот на процесот на пенење. Системите за регулација на температурата од водечките производители на машина за пенење полиуретан ги одржуваат температурите на компонентите во строги параметри, спречувајќи прематурни реакции, а истовремено осигуруваат правилно ширење и исушиување на пената. Примената на опремата обфаќа бројни сектори, вклучувајќи автомобилски седишта и интериерни делови, јастуци за мебел, изолациони плочи за градежништво, материјали за пакување и специјализирани индустријски применувања. Многу производители на машина за пенење полиуретан нудат прилагодливи конфигурации за да се задоволат специфичните производствени потреби, од единици за мали прототипи до линии за масовна производство способни да произведуваат илјадници делови дневно. Напредните модели вклучуваат автоматизирани циклуси за чистење, системи за рециркулација на материјалот и вградени мерки за контрола на квалитетот кои минимизираат отпад додека максимално ја зголемуваат ефикасноста. Технолошката софистицираност на современите производители на машина за пенење полиуретан се проширува и на пријателски кориснички интерфејси, можност за далечинско следење и функции за предвидување на одржувањето, што ја намалува нетрпеливоста и оптимизира работните перформанси во разновидни производствени средини.