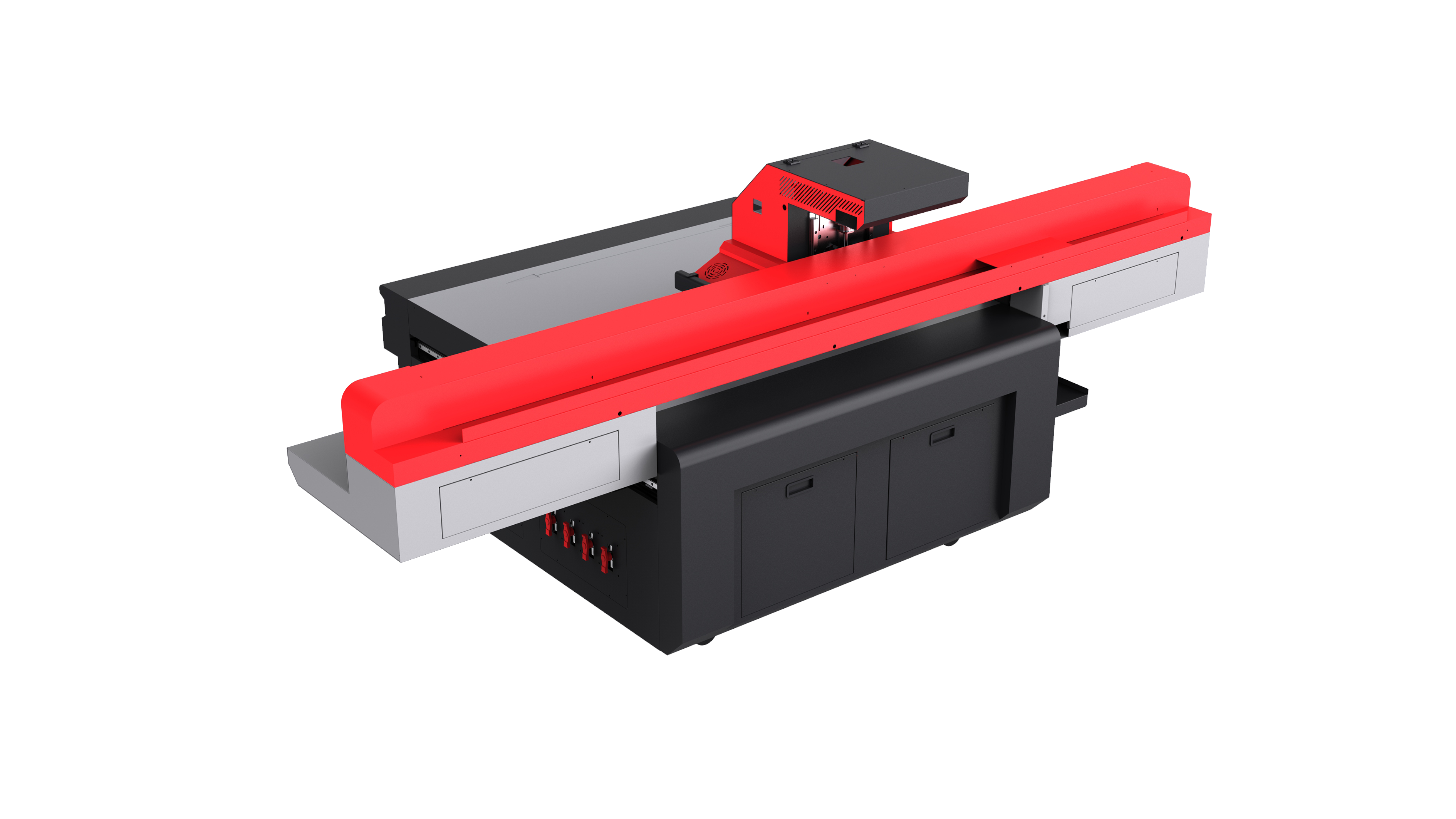

uv flatbed printer machine

ເຄື່ອງພິມແບບພື້ນຮາບ uv ແມ່ນການພັດທະນາຢ່າງໃຫຍ່ຫຼວງໃນດ້ານເຕັກໂນໂລຊີການພິມດິຈິຕອລ, ຖືກອອກແບບມາເພື່ອສະໜອງຄຸນນະພາບການພິມທີ່ດີເລີດໃນວັດສະດຸຕ່າງໆ ດ້ວຍຄວາມຖືກຕ້ອງ ແລະ ປະສິດທິຜົນສູງ. ລະບົບການພິມຂັ້ນສູງນີ້ໃຊ້ເຕັກໂນໂລຊີໄຟ LED ແສງ UV ເພື່ອແຂງຕົວໝຶກທັນທີທີ່ສຳຜັດກັບວັດສະດຸ, ເຮັດໃຫ້ສາມາດຈັດການ ແລະ ສຳເລັດຜົນຜະລິດທີ່ພິມແລ້ວໄດ້ທັນທີ. ຕ່າງຈາກວິທີການພິມແບບດັ້ງເດີມ, ເຄື່ອງພິມແບບພື້ນຮາບ uv ສາມາດຮັບວັດສະດຸທັງໝົດທັງທີ່ຍືດຫຍຸ່ນ ແລະ ທີ່ແຂງ, ຈາກເຈ້ຍ ແລະ ວິນີລິກ ໄປຫາແກ້ວ, ໂລຫະ, ໄມ້, ເຊລາມິກ ແລະ ພື້ນຜິວ acrylic. ຮູບຮ່າງພື້ນຮາບຂອງເຄື່ອງຊ່ວຍໃຫ້ສາມາດພິມໂດຍກົງໂດຍບໍ່ຈຳເປັນຕ້ອງຕິດຕັ້ງ ຫຼື ກຽມພ້ອມລ່ວງໜ້າ, ຊຶ່ງຊ່ວຍຫຼຸດເວລາການຜະລິດ ແລະ ການສູນເສຍວັດສະດຸໄດ້ຢ່າງຫຼວງຫຼາຍ. ຄຸນສົມບັດເຕັກນິກຫຼັກໆ ລວມມີ ເຕັກໂນໂລຊີໝຶກດຣອບເປັນຕົວປ່ຽນແປງທີ່ສາມາດຜະລິດສີທີ່ລະອຽດ ແລະ ຕົວໜັງສືທີ່ຊັດເຈນ, ລະບົບການຈັດການສີຂັ້ນສູງທີ່ຮັບປະກັນການສະແດງສີຢ່າງສອດຄ່ອງ, ແລະ ໂມດູນການຈັດການວັດສະດຸທີ່ຖືກຕ້ອງຊ່ວຍຮັກສາຄວາມຖືກຕ້ອງໃນຂະນະກຳລັງພິມ. ຄວາມສາມາດໃນການໃຊ້ໝຶກສີຂາວຂອງເຄື່ອງພິມແບບພື້ນຮາບ uv ສ່ວນຫຼາຍຊ່ວຍໃຫ້ສາມາດພິມໃສ່ພື້ນຜິວທີ່ມືດ ຫຼື ສົດໃສ, ເຊິ່ງຂະຫຍາຍທາງເລືອກໃນການສ້າງສັນຢ່າງກ້ວາງຂວາງ. ເຄື່ອງທີ່ທັນສະໄໝມີເຕັກໂນໂລຊີຫົວພິມອັດສະລິຍະພາບພ້ອມລະບົບລ້າງອັດຕະໂນມັດ, ຊ່ວຍຫຼຸດຄວາມຕ້ອງການໃນການບຳລຸງຮັກສາ ແລະ ຮັບປະກັນປະສິດທິພາບທີ່ສອດຄ່ອງ. ເຊັນເຊີ້ວັດຄວາມສູງຈະກຳນົດຄວາມໜາຂອງວັດສະດຸອັດຕະໂນມັດ, ເພື່ອປັບຕຳແໜ່ງຫົວພິມໃຫ້ເໝາະສົມກັບວັດສະດຸຕ່າງໆ. ລະບົບດູດແຮງດູດຊ່ວຍຈັບວັດສະດຸໄວ້ຢ່າງໜັກແໜ້ນໃນຂະນະກຳລັງພິມ, ບໍ່ໃຫ້ເກີດການຂະຫຍັບທີ່ອາດຈະສົ່ງຜົນກະທົບຕໍ່ຄຸນນະພາບການພິມ. ລະບົບຄວບຄຸມອຸນຫະພູມຮັກສາເງື່ອນໄຂການເຮັດວຽກໃຫ້ເໝາະສົມ, ຮັບປະກັນການຕິດຂອງໝຶກ ແລະ ປະສິດທິຜົນໃນການແຂງຕົວໝຶກໃນສະພາບແວດລ້ອມທີ່ແຕກຕ່າງກັນ. ການເຂົ້າກັນໄດ້ຂອງຊອບແວຂັ້ນສູງຊ່ວຍໃຫ້ສາມາດເຊື່ອມຕໍ່ຢ່າງລຽບງ່າຍກັບໂປຣແກຣມອອກແບບທີ່ນິຍົມ, ເຮັດໃຫ້ຂະບວນການຈາກແນວຄິດໄປສູ່ຜົນຜະລິດສຳເລັດມີຄວາມລຽບງ່າຍ. ເຄື່ອງພິມແບບພື້ນຮາບ uv ມັກຈະມີການຈັດລຽງໝຶກຫຼາຍຮູບແບບ, ລວມທັງ CMYK ບວກກັບໝຶກສີຂາວ ແລະ ເງົາຄົນເຮັດດ້ວຍໝຶກໂປ່ງໃສ, ຊ່ວຍໃຫ້ມີຄວາມຫຼາກຫຼາຍສຳລັບການນຳໃຊ້ໃນການພິມທີ່ແຕກຕ່າງກັນໃນອຸດສາຫະກຳຕ່າງໆ ເຊັ່ນ: ປ້າຍ, ການຫຸ້ມຫໍ່, ຜະລິດຕະພັນໂຄສະນາ, ແລະ ການຜະລິດຕາມຄຳສັ່ງ