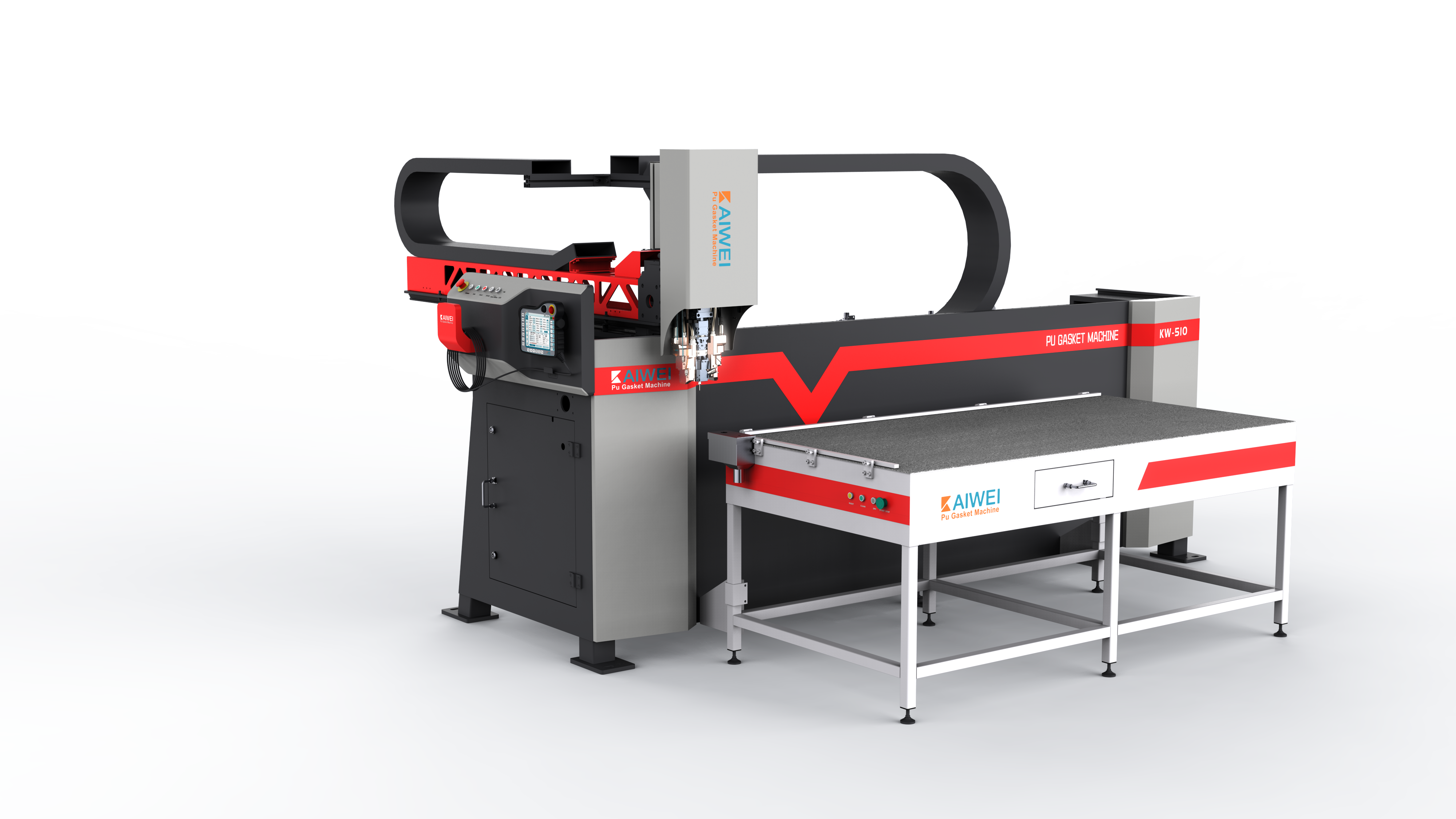

melhor máquina de colagem de selo pu

A melhor máquina de colagem com selante de poliuretano representa um avanço revolucionário nas aplicações de vedação automotiva e industrial, oferecendo aplicação precisa de adesivo de poliuretano com precisão excepcional. Este equipamento sofisticado combina tecnologia avançada de automação com operação amigável, otimizando os processos produtivos em diversas indústrias. A máquina possui sistemas dispensadores acionados por servomotores que garantem taxas constantes de fluxo de adesivo, eliminando desperdícios e assegurando qualidade uniforme do selante. Sua interface de controle programável permite aos operadores personalizar padrões de dispensação, ajustes de pressão e sequências temporizadas para atender diferentes requisitos de fabricação. A melhor máquina de colagem com selante de poliuretano incorpora sistemas de aquecimento com controle de temperatura que mantêm a viscosidade ideal para materiais de poliuretano, evitando problemas de cura e garantindo uma boa aderência. O equipamento utiliza mecanismos de bombeamento de precisão com capacidades de monitoramento em tempo real, fornecendo feedback instantâneo sobre o consumo de adesivo e parâmetros de aplicação. Versões modernas incluem telas sensíveis ao toque com interfaces de programação intuitivas, reduzindo o tempo de treinamento dos operadores e minimizando erros de configuração. A construção robusta da máquina apresenta componentes resistentes à corrosão, projetados para operação contínua em ambientes industriais exigentes. Os sistemas de segurança incluem paradas de emergência, invólucros protetores e ciclos de limpeza automatizados que mantêm o desempenho ideal enquanto protegem o pessoal. As capacidades de integração permitem conexão perfeita com linhas de produção existentes por meio de protocolos de comunicação padrão. A tecnologia do cabeçote dispensador oferece perfis de cordão consistentes com parâmetros ajustáveis de largura e espessura, atendendo a diversos requisitos de vedação, desde juntas automotivas até vedações industriais. Modelos avançados incorporam sistemas de visão para verificação de qualidade, detectando automaticamente irregularidades na aplicação e acionando ações corretivas. A melhor máquina de colagem com selante de poliuretano suporta múltiplas formulações de adesivos, incluindo sistemas de poliuretano de um componente e de dois componentes, proporcionando flexibilidade na fabricação para diversas aplicações, desde a instalação de vidros até a vedação de componentes eletrônicos.