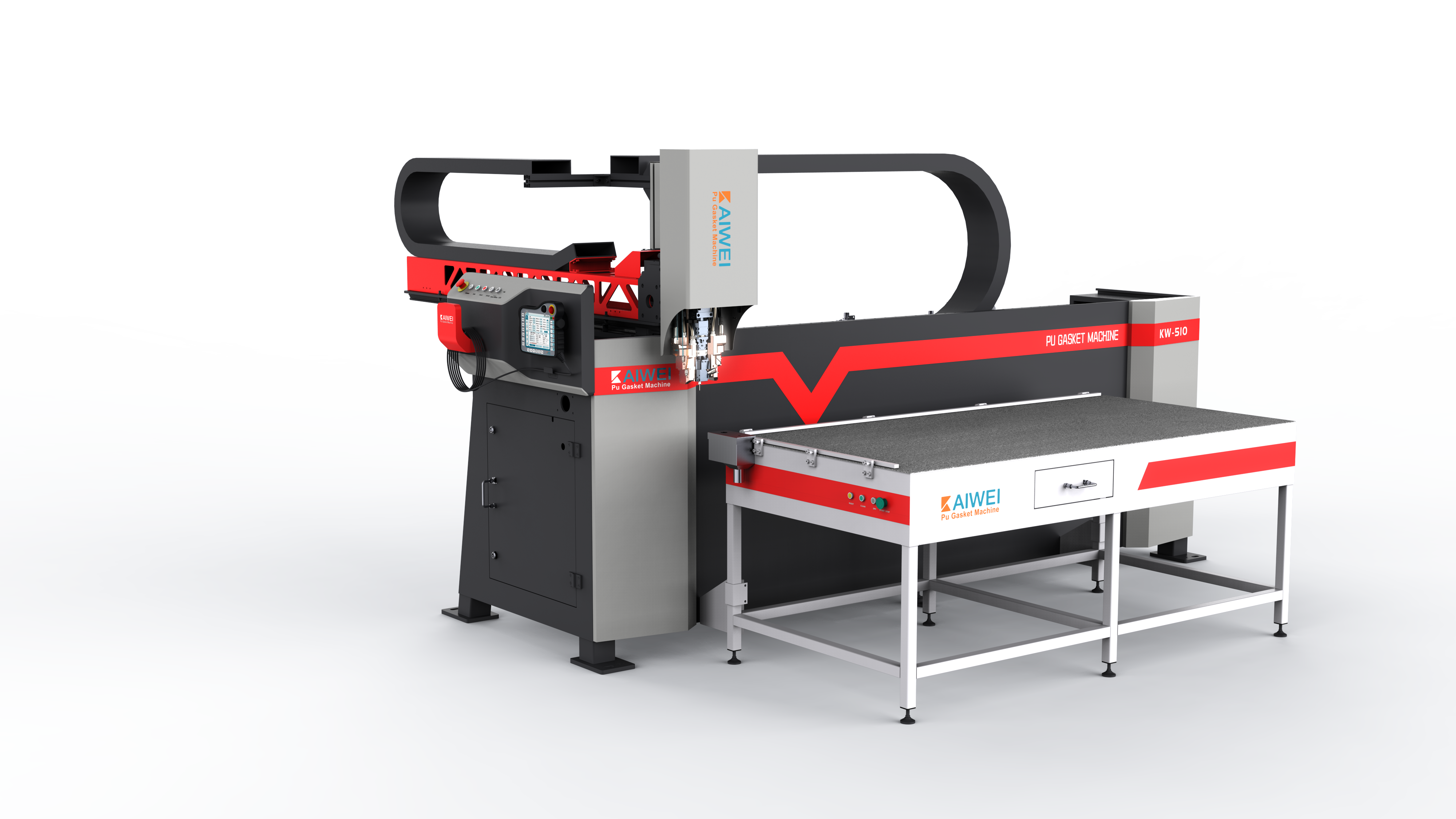

best pu seal gluing machine

The best pu seal gluing machine represents a revolutionary advancement in automotive and industrial sealing applications, delivering precision polyurethane adhesive application with exceptional accuracy. This sophisticated equipment combines cutting-edge automation technology with user-friendly operation to streamline production processes across multiple industries. The machine features advanced servo-driven dispensing systems that ensure consistent adhesive flow rates, eliminating waste and guaranteeing uniform seal quality. Its programmable control interface allows operators to customize dispensing patterns, pressure settings, and timing sequences for diverse manufacturing requirements. The best pu seal gluing machine incorporates temperature-controlled heating systems that maintain optimal viscosity for polyurethane materials, preventing curing issues and ensuring proper adhesion. The equipment utilizes precision pumping mechanisms with real-time monitoring capabilities, providing instant feedback on adhesive consumption and application parameters. Modern versions include touchscreen displays with intuitive programming interfaces that reduce operator training time and minimize setup errors. The machine's robust construction features corrosion-resistant components designed for continuous operation in demanding industrial environments. Safety systems include emergency stops, protective enclosures, and automated cleaning cycles that maintain optimal performance while protecting personnel. Integration capabilities allow seamless connection with existing production lines through standard communication protocols. The dispensing head technology delivers consistent bead profiles with adjustable width and thickness parameters, accommodating various seal requirements from automotive gaskets to industrial weatherstripping. Advanced models incorporate vision systems for quality verification, automatically detecting dispensing irregularities and triggering corrective actions. The best pu seal gluing machine supports multiple adhesive formulations including one-component and two-component polyurethane systems, providing manufacturing flexibility for diverse applications ranging from window installation to electronic component sealing.