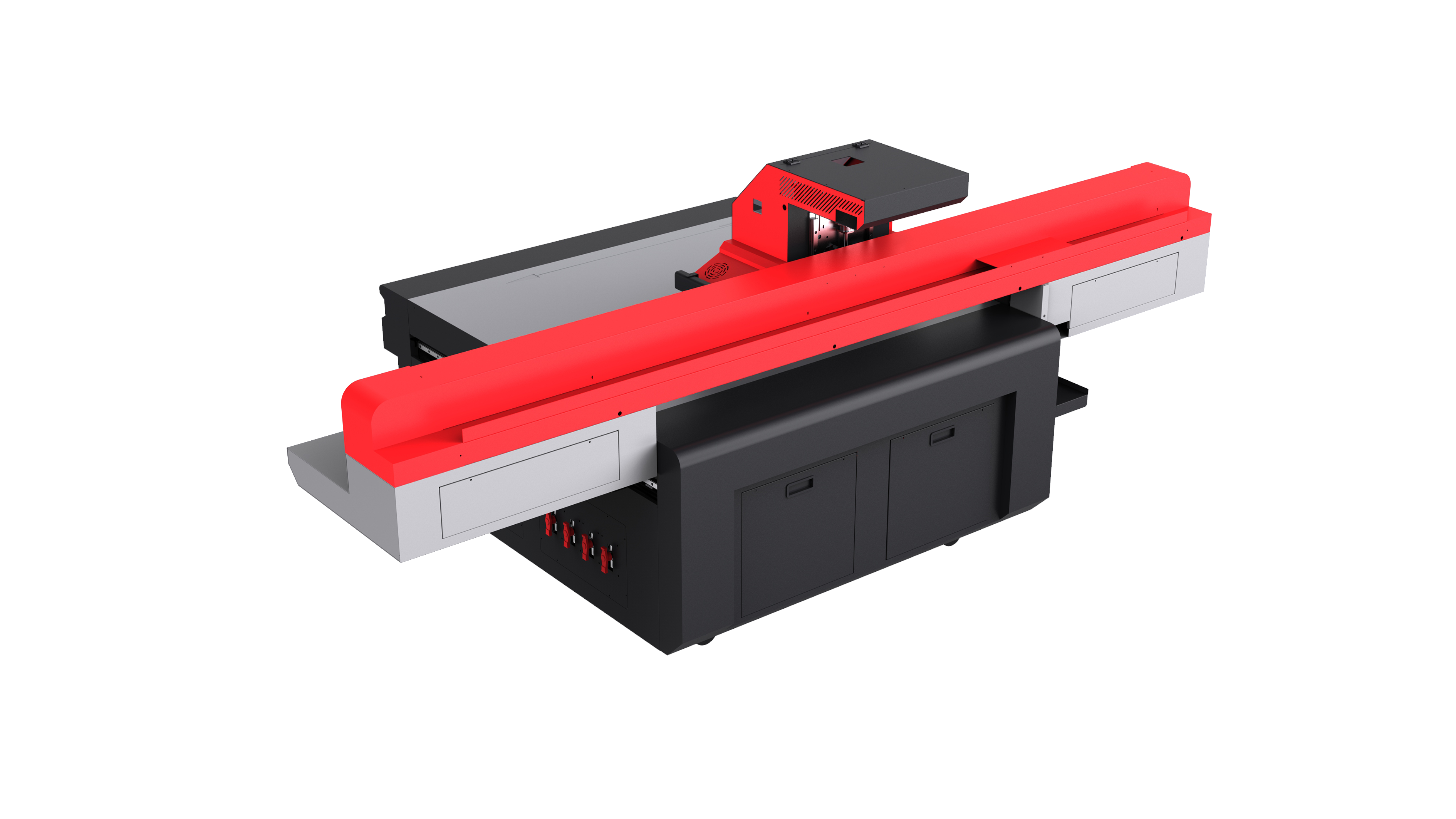

imprimantă uv flatbed de înaltă calitate

Imprimanta plană UV de înaltă calitate reprezintă un avans revoluționar în tehnologia de imprimare digitală, oferind versatilitate și precizie fără precedent pentru afaceri din multiple industrii. Această soluție sofisticată de imprimare utilizează tehnologia de uscare cu LED ultraviolet pentru a usca și fixa instantaneu cerneala, permițând imprimarea pe practic orice material rigid sau flexibil, cu o grosime de până la câțiva centimetri. Spre deosebire de metodele tradiționale de imprimare, o imprimantă plană UV de înaltă calitate poate prelucra materiale precum sticlă, metal, lemn, dar și plastice, ceramică și textile, fără a necesita pretratare sau acoperiri speciale. Designul plat permite acceptarea obiectelor cu diverse grosimi și forme neregulate, fiind ideal pentru aplicații de imprimare tridimensională. Capetele avansate de imprimare oferă o rezoluție excepțională, până la 1440 dpi, asigurând texte clare, culori vii și degradări uniforme, care respectă standardele profesionale. Procesul de fixare UV creează tipărituri durabile, rezistente la zgârieturi, care își mențin integritatea culorii chiar și în condiții dificile de mediu. Modelele moderne de imprimante plane UV de înaltă calitate includ sisteme inteligente de gestionare a culorii care se calibrează automat în funcție de diferitele suporturi, asigurând o calitate constantă a produselor finite pe întregul ciclu de producție. Capacitatea de imprimare cu date variabile permite personalizarea și customizarea la viteze de producție, în timp ce opțiunea de cerneală albă face posibilă imprimarea pe materiale întunecate sau transparente. Designul modular al imprimantei facilitează întreținerea și actualizările ușoare, prelungind durata de viață a echipamentului și protejând investiția. Funcțiile automate includ detectarea suportului, alinierea capetelor de imprimare și monitorizarea nivelului de cerneală, reducând intervenția operatorului și minimizând erorile. Beneficiile ecologice includ funcționarea fără solvenți și generarea redusă de deșeuri comparativ cu procesele tradiționale de imprimare. Capacitatea imprimantei plane UV de înaltă calitate de a imprima direct pe produsele finite elimină etape intermediare precum montarea sau laminarea, reducând timpul și costurile de producție, în timp ce îmbunătățește durabilitatea și aspectul final al produsului.