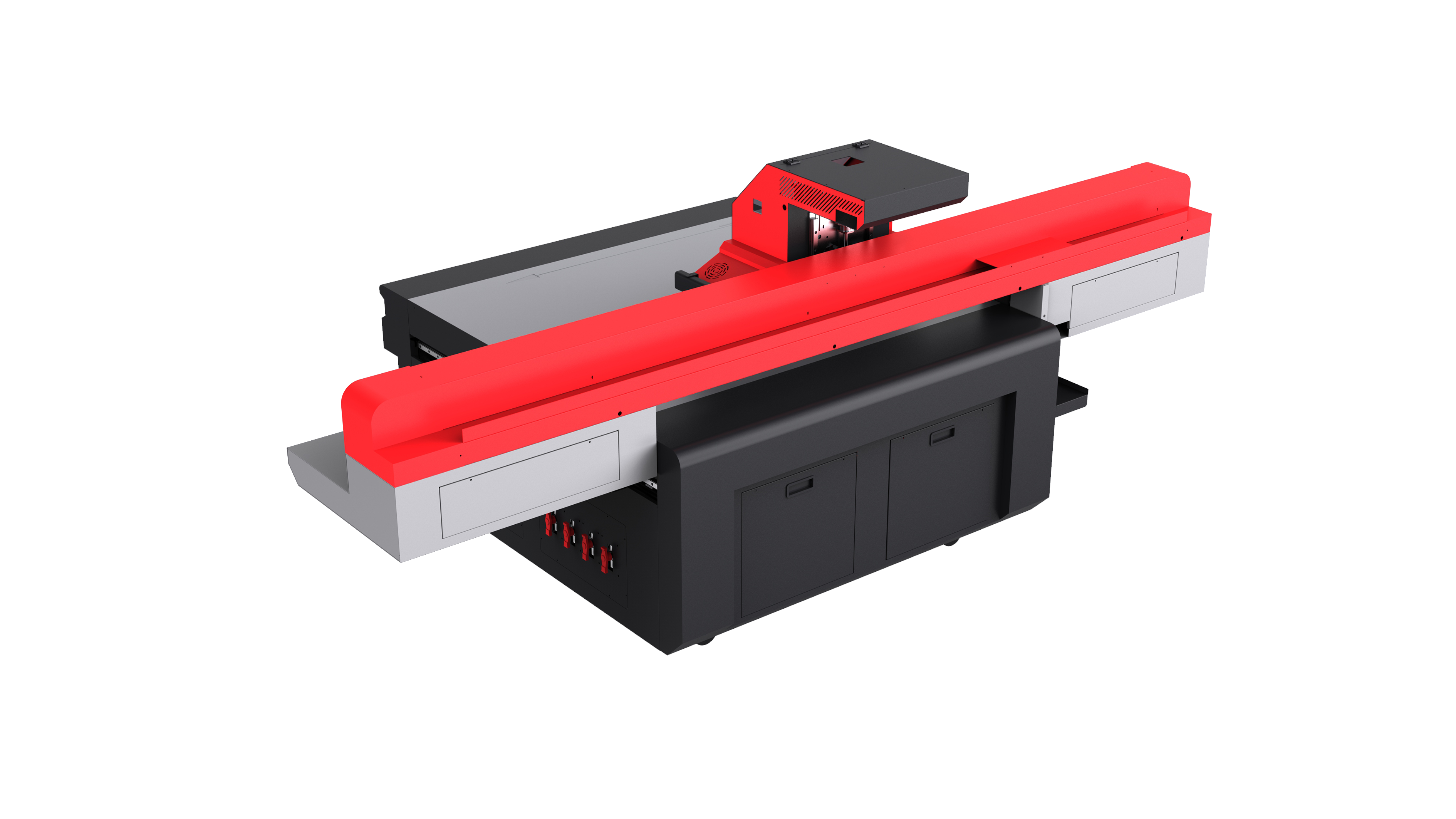

Versatilitate Excepțională în Imprimarea Multi-Material Extinde Oportunitățile de Afaceri

Sistemele de imprimare UV digital cu plată mobilă se remarcă prin compatibilitatea lor excelentă cu multiple materiale, permițând companiilor să-și diversifice ofertele de servicii și să acceseze noi segmente de piață anterior inaccesibile cu tehnologiile convenționale de imprimare. Această versatilitate provine din proprietățile unice ale cerurilor UV-curable, care aderă eficient atât la suprafețele poroase, cât și la cele neporoase, fără a necesita amorsări, agenți de aderență sau tratamente de suprafață. Substraturile rigide, de la hârtie și carton la metale, ceramice și plasticuri inginerești, primesc tipărituri consistente și de înaltă calitate, cu caracteristici excelente de aderență. Designul cu plată mobilă permite materialelor cu o grosime de până la câțiva centimetri să fie procesate, facilitând decorarea obiectelor tridimensionale și aplicarea marcajelor pe piese industriale. Capacitățile de imprimare pe sticlă deschid oportunități în domeniile vitraliilor arhitecturale, panourilor decorative și semnelor comerciale, unde metodele tradiționale sunt inadecvate sau prea costisitoare. Compatibilitatea cu substraturile metalice include aluminiu, oțel, alamă și aliaje speciale utilizate în aplicații auto, aero-spațiale și industriale, unde durabilitatea și rezistența chimică sunt esențiale. Imprimarea pe lemn depășește semnele tradiționale, incluzând decorarea mobilierului, lucrările de tâmplărie arhitecturală și proiectele personalizate de creație, care beneficiază de redare de calitate fotografică. Imprimarea textilă pe panouri rigide din material textil, table de pânză și materiale compozite permite reproducerea artelor plastice și aplicații industriale specializate. Capacitatea de a imprima pe suprafețe curbe sau ușor neregulate, prin poziționarea reglabilă a capetelor de imprimare, extinde posibilitățile de aplicație la obiecte cilindrice, piese turnate și elemente arhitecturale. Posibilitatea utilizării cerului alb permite imprimarea pe substraturi întunecate sau transparente, creând efecte vizuale spectaculoase și extinzând opțiunile de design. Cerurile speciale, inclusiv formule metalice, fluorescente și texturate, adaugă valoare superioară produselor finite, menținând în același timp beneficiile de durabilitate ale uscării UV. Sistemul poate gestiona sarcini de lucru cu grosimi mixte în cadrul aceleiași serii de producție, optimizând eficiența în procesarea unor specificații variate de material. Cerințele de pregătire a suprafeței rămân minime, reducând timpul și costurile de preprocesare, în timp ce se mențin standarde constante de calitate. Sistemele de control al calității monitorizează poziționarea substratului și caracteristicile suprafeței, ajustând automat parametrii de imprimare pentru a compensa variațiile materialelor și pentru a asigura rezultate optime pe diverse tipuri de substraturi.