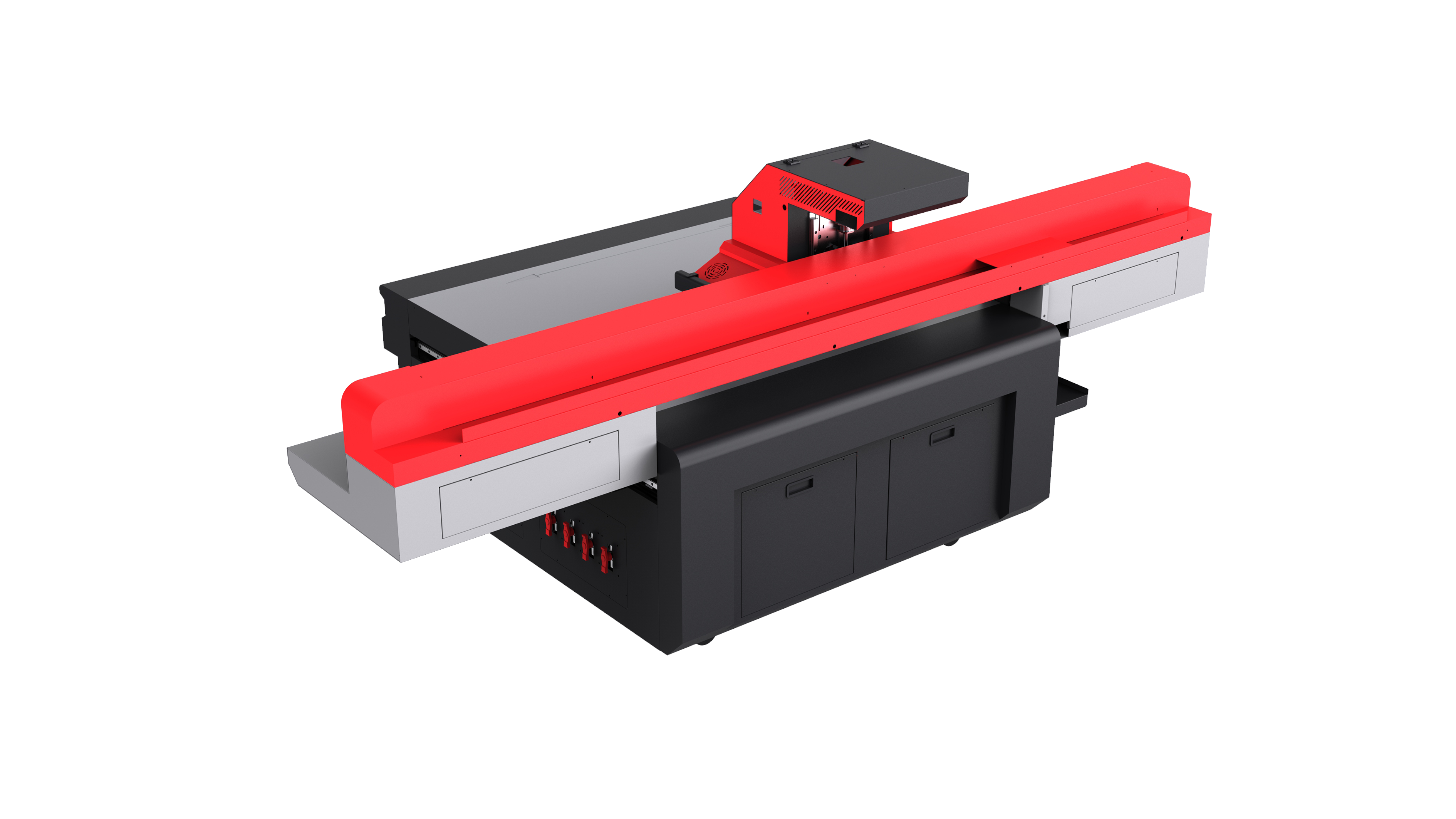

Exceptional Multi-Material Printing Versatility Expands Business Opportunities

UV digital flatbed printer wholesale systems excel in multi-material compatibility, enabling businesses to diversify their service offerings and capture new market segments previously inaccessible with conventional printing technologies. This versatility stems from the unique properties of UV-curable inks that adhere effectively to both porous and non-porous surfaces without requiring primers, adhesion promoters, or surface treatments. Rigid substrates ranging from paper and cardboard to metals, ceramics, and engineered plastics receive consistent, high-quality prints with excellent adhesion characteristics. The flatbed design accommodates materials up to several inches thick, enabling three-dimensional object decoration and industrial part marking applications. Glass printing capabilities open opportunities in architectural glazing, decorative panels, and commercial signage where traditional methods prove inadequate or cost-prohibitive. Metal substrate compatibility includes aluminum, steel, brass, and specialty alloys used in automotive, aerospace, and industrial applications where durability and chemical resistance are paramount. Wood printing extends beyond traditional signage to include furniture decoration, architectural millwork, and custom crafting projects that benefit from photographic-quality reproduction. Textile printing on rigid fabric panels, canvas boards, and composite materials enables fine art reproduction and specialized industrial applications. The ability to print on curved or slightly irregular surfaces through adjustable print head positioning expands application possibilities to cylindrical objects, molded parts, and architectural elements. White ink capabilities enable printing on dark or transparent substrates, creating striking visual effects and expanding design possibilities. Specialty inks including metallic, fluorescent, and textured formulations add premium value to finished products while maintaining the durability benefits of UV curing. The system handles mixed-thickness jobs within single production runs, optimizing efficiency when processing varied material specifications. Surface preparation requirements remain minimal, reducing preprocessing time and costs while maintaining consistent quality standards. Quality control systems monitor substrate positioning and surface characteristics, automatically adjusting print parameters to accommodate material variations and ensure optimal results across diverse substrate types.