Izjemna univerzalnost materiala in obseg uporabe

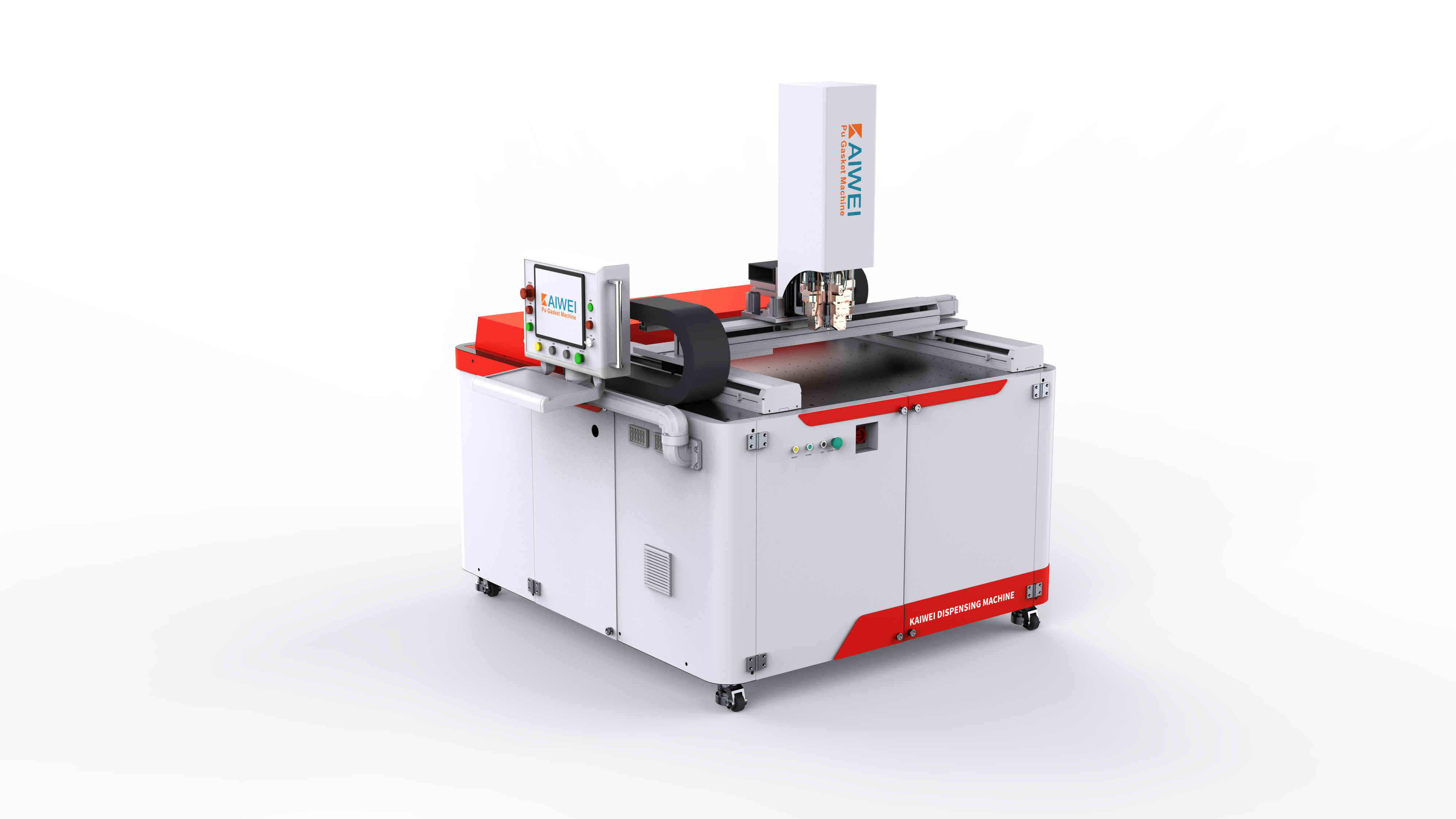

Stroj za tesnenje penastih tesnil prikazuje izjemno raznolikost materialov in obseg uporabe, ki rešuje različne proizvodne izzive v več industrijskih panogah in pri specializiranih zahtevah. Ta raznolikost zajema združljivost z mnogimi peninami kemijami, vključno s poliuretansko, silikonsko, EPDM, neoprensko in naprednimi specialnimi formulacijami, zasnovanimi za ekstremne okoljske pogoje. Stroj obdeluje materiale od spojin, ki vulkanizirajo pri sobni temperaturi, do toplotno aktiviranih sistemov, ki zahtevajo natančno regulacijo temperature med procesoma odvajanja in utrjevanja. Združljivost z materiali se razteza na različne viskoznosti, od nizko-viskoznih prodornih tesnil, ki predirajo v majhne reže, do visoko-viskoznih strukturnih materialov, ki ohranjajo dimensionalno stabilnost pod mehanskim napetostnim obremenitvijo. Stroj za penasta tesnila omogoča uporabo enosložnih pripravljenih za uporabo materialov ter zapletenih večkomponentnih sistemov, ki zahtevajo natančno mešanje razmerij in upravljanje življenjske dobe mešanice. Raznolikost uporabe sega od tankih tesnil za tesnjenje vrat, ki merijo manj kot en milimeter, do debelih strukturnih tesnil, ki presegajo deset milimetrov v prerezu. Oprema uspešno obdeluje materiale z različnimi lastnostmi razširjanja, od nizko razširjajočih natančnostnih tesnil do visoko razširjajočih aplikacij za zapolnjevanje rež. Okoljska združljivost pokriva materiale, ocenjene za ekstremne temperature, od kriogenskih aplikacij do visokotemperaturnih avtomobilskih motorjev. Možnosti kemične odpornosti vključujejo materiale, zasnovane za stik z gorivi, olji, kislinami, bazami in različnimi industrijskimi kemikalijami. Stroj obdeluje specialne materiale, vključno s tistimi, ki prevajajo električni tok za elektromagnetno zaščito, protipožarnimi spojinami za varnostno kritične aplikacije ter materiali za hrano primernimi za uporabo v aparaturi in embalaži. Prilagodljivost časa utrjevanja omogoča uporabo materialov z cikli utrjevanja od sekund do ur, pri čemer vgrajeni sistemi upravljajo pogoje temperature, vlažnosti in zračnega toka, da optimizirajo zmogljivost vsakega materiala. Obseg uporabe sega na tesnila avtomobilskih vrat, tesnila ohišij elektronike, tesnjenje ohišij aparatur, komponente medicinskih naprav in zaščito industrijske opreme pred vremenskimi vplivi. Ta izjemna raznolikost odpravlja potrebo po več specializiranih strojih, zmanjšuje kapitalske naložbe in hkrati maksimalno povečuje proizvodno prilagodljivost ter proizvajalcem omogoča hitro odzivanje na spreminjajoče se tržne zahteve in stranke specifikacije.