วิธีการปรับปรุงประสิทธิภาพด้วยอัตโนมัติการปิดฟอง

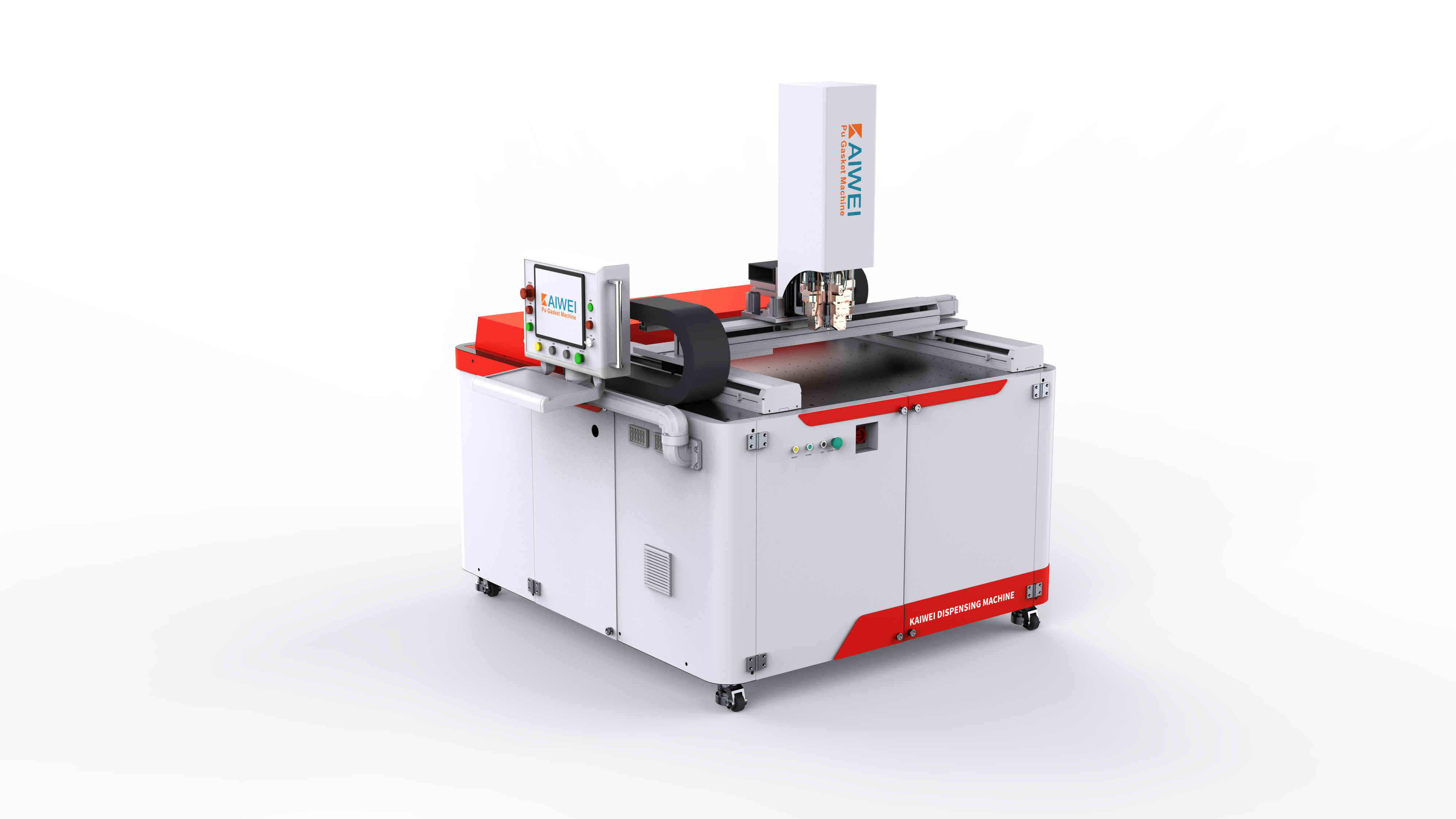

การปรับปรุงการผลิตผ่านการปิดฟองอัตโนมัติ ในภูมิทัศน์การผลิตที่เปลี่ยนแปลง การมีประสิทธิภาพและความละเอียดถูกต้องได้กลายเป็นสิ่งสําคัญในการรักษาข้อดีในการแข่งขัน การบูรณาการของอัตโนมัติในกระบวนการปิดฟองได้เปลี่ยน...

ดูเพิ่มเติม