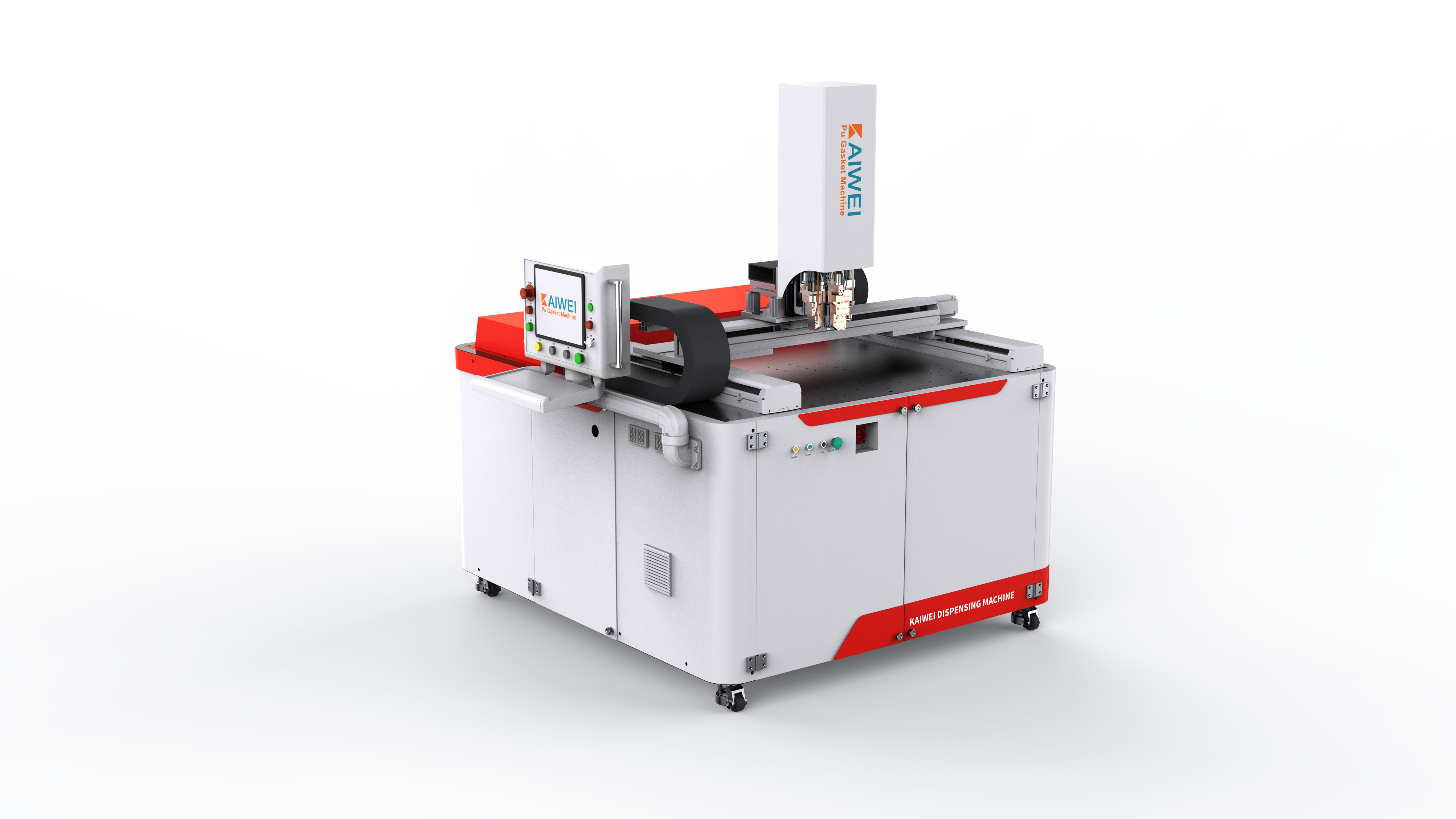

automatic foam gasket machine

The automatic foam gasket machine represents a revolutionary advancement in industrial sealing technology, designed to streamline the production of high-quality foam gaskets across various manufacturing sectors. This sophisticated equipment combines precision engineering with automated functionality to deliver consistent, reliable gasket production that meets demanding industrial standards. The automatic foam gasket machine operates through a comprehensive system that integrates cutting, shaping, and finishing processes into one seamless workflow. At its core, the machine utilizes advanced servo motor technology to ensure precise movement and positioning during the gasket creation process. The main functions encompass material feeding, automated cutting patterns, dimensional accuracy control, and quality inspection protocols. The technological features include programmable logic controllers that allow operators to customize gasket specifications according to specific requirements. The machine incorporates high-resolution vision systems for real-time quality monitoring, ensuring each gasket meets predetermined standards before completion. Temperature control systems maintain optimal processing conditions for various foam materials, while pressure regulation mechanisms ensure consistent compression and density throughout the gasket formation process. The automatic foam gasket machine finds extensive applications across automotive manufacturing, aerospace industries, electronics assembly, HVAC systems, and marine equipment production. In automotive applications, these machines produce door seals, window gaskets, and engine compartment sealing components. Aerospace manufacturers rely on these systems for creating specialized gaskets that withstand extreme environmental conditions. The electronics industry benefits from precision micro-gaskets that protect sensitive components from moisture and dust infiltration. HVAC applications include ductwork sealing gaskets and equipment housing seals. The machine's versatility extends to custom gasket production for specialized industrial equipment, medical device manufacturing, and consumer appliance assembly. The integration of Industry 4.0 connectivity features allows for remote monitoring, predictive maintenance scheduling, and production data analytics, making the automatic foam gasket machine an essential component of modern smart manufacturing environments.