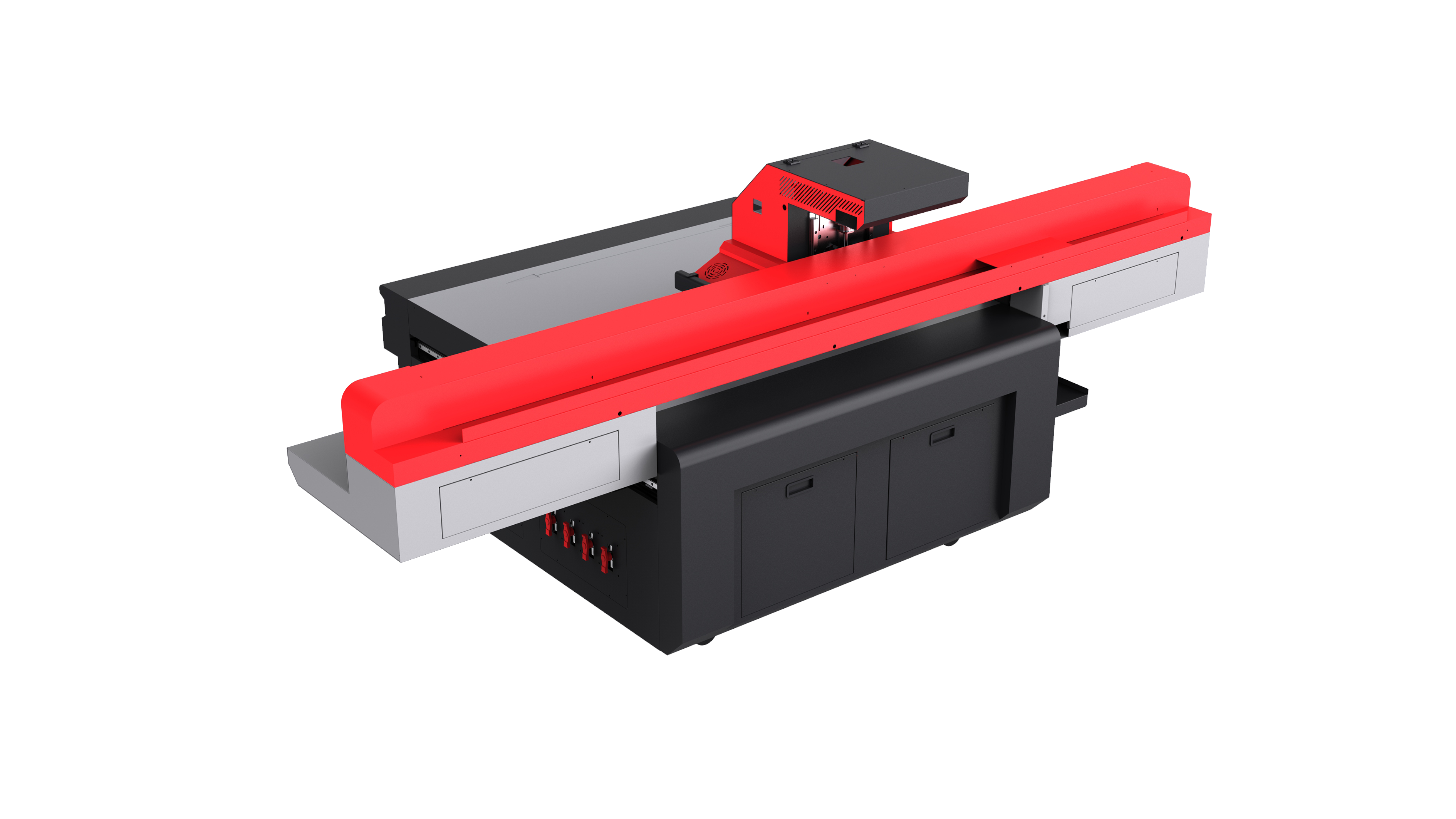

Revolutionary UV Curing Technology for Instant Results

The a3 uv flatbed printer incorporates cutting-edge ultraviolet curing technology that fundamentally transforms the printing process by delivering instant, permanent results that surpass traditional printing methods in both quality and efficiency. This innovative system utilizes high-intensity LED UV lamps strategically positioned to cure specially formulated UV inks immediately upon application to the substrate surface. The instantaneous curing process creates a chemical reaction that polymerizes the ink, forming a durable, scratch-resistant surface that bonds permanently with the substrate material. This technology eliminates the traditional waiting period associated with solvent evaporation or absorption-based drying methods, allowing printed materials to be immediately handled, processed, or shipped without risk of smudging, offsetting, or quality degradation. The UV curing process creates prints with exceptional durability characteristics, including superior resistance to fading, moisture, chemicals, and physical abrasion. This makes the a3 uv flatbed printer particularly valuable for producing outdoor signage, industrial labels, promotional materials, and decorative items that must withstand harsh environmental conditions while maintaining their original appearance and functionality. The technology enables printing on heat-sensitive materials that would be damaged by traditional thermal drying processes, expanding the range of suitable substrates to include thin plastics, synthetic materials, and temperature-sensitive composites. The precision of UV curing allows for the creation of raised textures and dimensional effects that add tactile qualities to printed surfaces, enhancing the perceived value and visual appeal of finished products. Energy efficiency represents another significant benefit of this technology, as LED UV systems consume substantially less power than traditional curing methods while generating minimal heat, creating a more comfortable working environment and reducing operational costs. The consistent curing process ensures uniform print quality across the entire substrate surface, eliminating the variations and imperfections commonly associated with conventional drying methods that can be affected by environmental factors such as humidity, temperature, and air circulation.