Изузетна разновидност на материјали за безгранични креативни можности

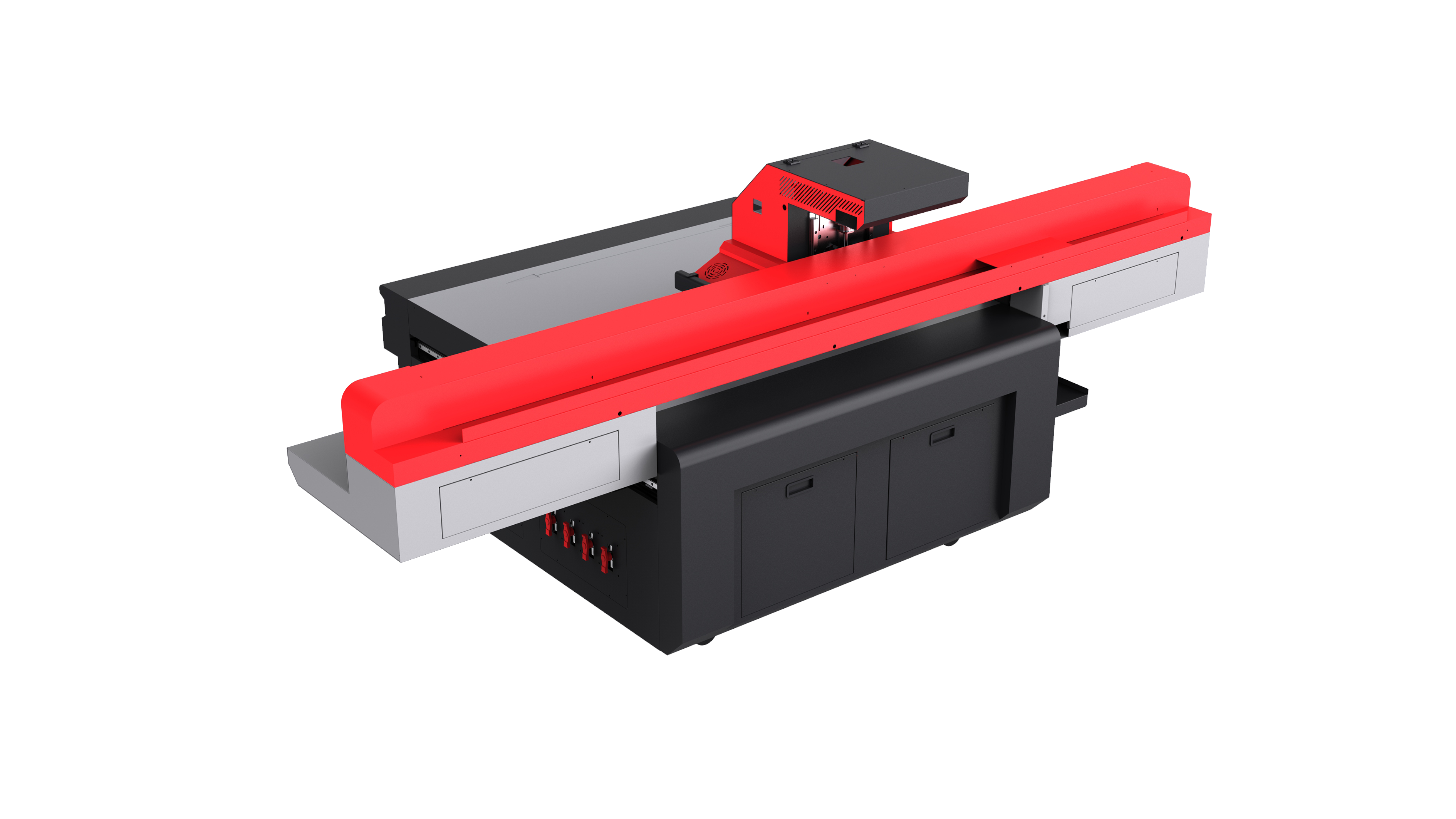

Принтерот a3 uv флетбед истакнува во индустријата на печатење со својата извонредна способност да произведува печатења од високо квалитет врз извонредно разновидни подложни материјали, ефективно елиминирајќи ги традиционалните ограничувања кои ја ограничуваат креативната изразеност и комерцијалната примена. Оваа флексибилност потекнува од единствената комбинација на УВ-технологија за мастила и флетбед дизајнот, кој овозможува користење на материјали што се движат од плочки како хартија до крути табли со дебелина од неколку инчи. Принтерот успешно работи со традиционални подложни материјали како хартија, картон и винил, но истовремено се истакнува и кај нетрадиционални материјали како метални лимови, стаклени плочи, дрвени табли, керамички плочки, пластика, кожени производи, ткаенински примероци и дури и тродимензионални објекти со неправилни површини. Оваа можност отвора неограничени креативни можности за дизајнери, произведувачи и услуги кои сега можат да нудат персонализирани услуги за печатење во повеќе индустрии и апликации, без потреба од инвестирање во посебна специјализирана опрема. Процесот на директно печатење врз подлогата елиминира потребата од скапи преносни медиуми, лепилни апликации или комплексни процедури за ламинација, значително ја намалува производствената цена и упростува работните процеси. Компатибилноста со материјали се протега и на крути и на флексибилни подложни материјали, овозможувајќи на компаниите да опслужуваат разновидни пазарни сегменти – од архитектонски знаци и индустријално означување, па сè до модни додатоци и промотивни производи. Системот за вакуумско придржување сигурно ги позиционира разновидните типови на материјали за време на печатењето, осигурувајќи прецизна регулација и спречување на поместување кое би можело да го компромитира квалитетот на печатењето, без разлика на дебелината, текстурата или површинските карактеристики на подлогата. Оваа функција е особено корисна при работа со полесни материјали кои можеби би се поместиле за време на конвенционалните процеси на печатење или со потешки материјали кои бараат сигурно позиционирање за точна дистрибуција на мастилото. Можноста да се печати на темни или обоени подложни материјали со користење бело мастило како база или прекривка создава можност за изразити визуелни ефекти и осигурува оптимална репродукција на боите, без разлика од основната боја на материјалот. Можноста за печатење на различни дебелини овозможува печатење врз предмети како што се кутии за телефони, награди, таблички и други тродимензионални производи, претворајќи го a3 uv флетбед принтерот во целосен производствен алат, а не само во традиционален печатен уред.