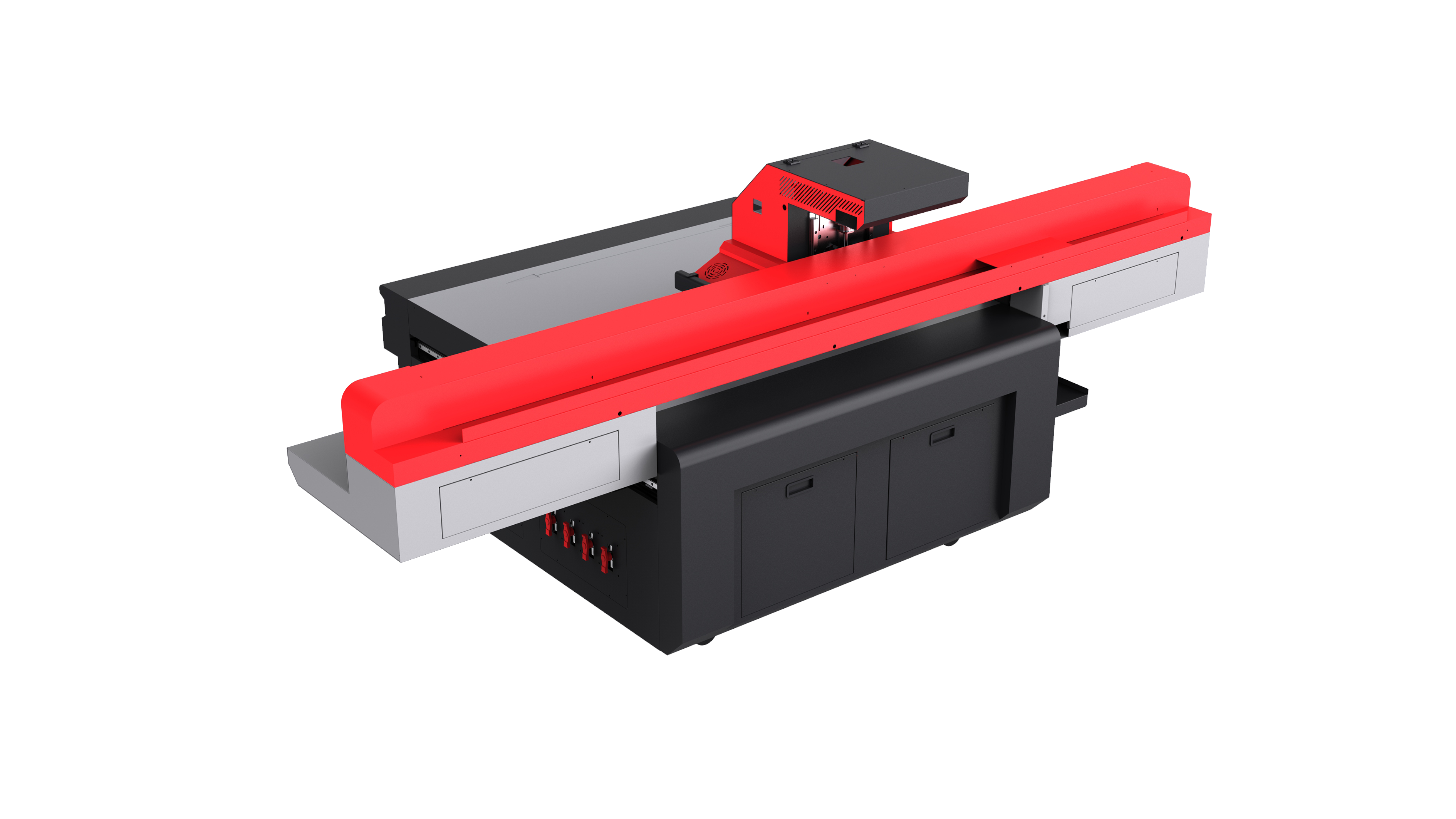

Izuzetna univerzalnost materijala za neograničene kreativne mogućnosti

A3 UV plosni tiskar ističe se u tiskarskoj industriji zahvaljujući izuzetnoj sposobnosti proizvodnje visokokvalitetnih tiskova na iznimno raznolikom rasponu materijala podloga, učinkovito uklanjajući tradicionalna ograničenja koja ograničavaju kreativni izraz i komercijalne primjene. Ova univerzalnost proizlazi iz jedinstvene kombinacije tehnologije UV tinte i konstrukcije s pločom koja prihvaća materijale od tankih kao papir do krutih ploča debljine nekoliko inča. Tiskar uspješno obrađuje tradicionalne podloge poput papira, kartona i vinila, istovremeno ostvarujući izvrsne rezultate s nekonvencionalnim materijalima uključujući limene ploče, staklene ploče, drvene daske, keramičke pločice, plastične dijelove, kožne artikle, uzorke tkanina, pa čak i trodimenzionalne predmete s neravnim površinama. Ova mogućnost otvara neograničene kreativne mogućnosti dizajnerima, proizvođačima i pružateljima usluga koji sada mogu nuditi usluge tiskanja po mjeri u više industrijskih sektora i primjena, bez potrebe za ulaganjem u posebnu specijaliziranu opremu. Postupak tiskanja izravno na podlogu eliminira potrebu za skupim prenosnim medijima, ljepljenjem ili složenim laminacijskim postupcima, znatno smanjujući troškove proizvodnje i pojednostavljujući radne tokove. Kompatibilnost s materijalima proteže se na krute i fleksibilne podloge, omogućavajući tvrtkama da zadovolje različite tržišne segmente – od arhitektonskih natpisa i industrijske označivanja do modnih dodataka i promocijske robe. Sustav vakuumskog pričvršćivanja sigurno fiksira različite vrste materijala tijekom tiskanja, osiguravajući točnu poziciju i sprječavajući pomake koji bi mogli ugroziti kvalitetu tiska, bez obzira na debljinu, teksturu ili karakteristike površine podloge. Ova značajka pokazuje se osobito korisnom kod rada s laganim materijalima koji se mogu pomaknuti tijekom konvencionalnih tiskarskih procesa, kao i s teškim materijalima koji zahtijevaju pouzdano pozicioniranje radi točnog nanošenja tinte. Mogućnost tiskanja na tamnim ili obojenim podlogama upotrebom bijele tinte kao baze ili prekrivača otvara mogućnosti za izražajnim vizualnim efektima i osigurava optimalnu reprodukciju boja bez obzira na boju osnovnog materijala. Mogućnost tiskanja na različitim debljinama omogućuje tisak na predmete poput kućišta za telefone, nagrada, pločica i drugih trodimenzionalnih proizvoda, pretvarajući A3 UV plosni tiskar u sveobuhvatni proizvodni alat, a ne samo u tradicionalni tiskarski uređaj.