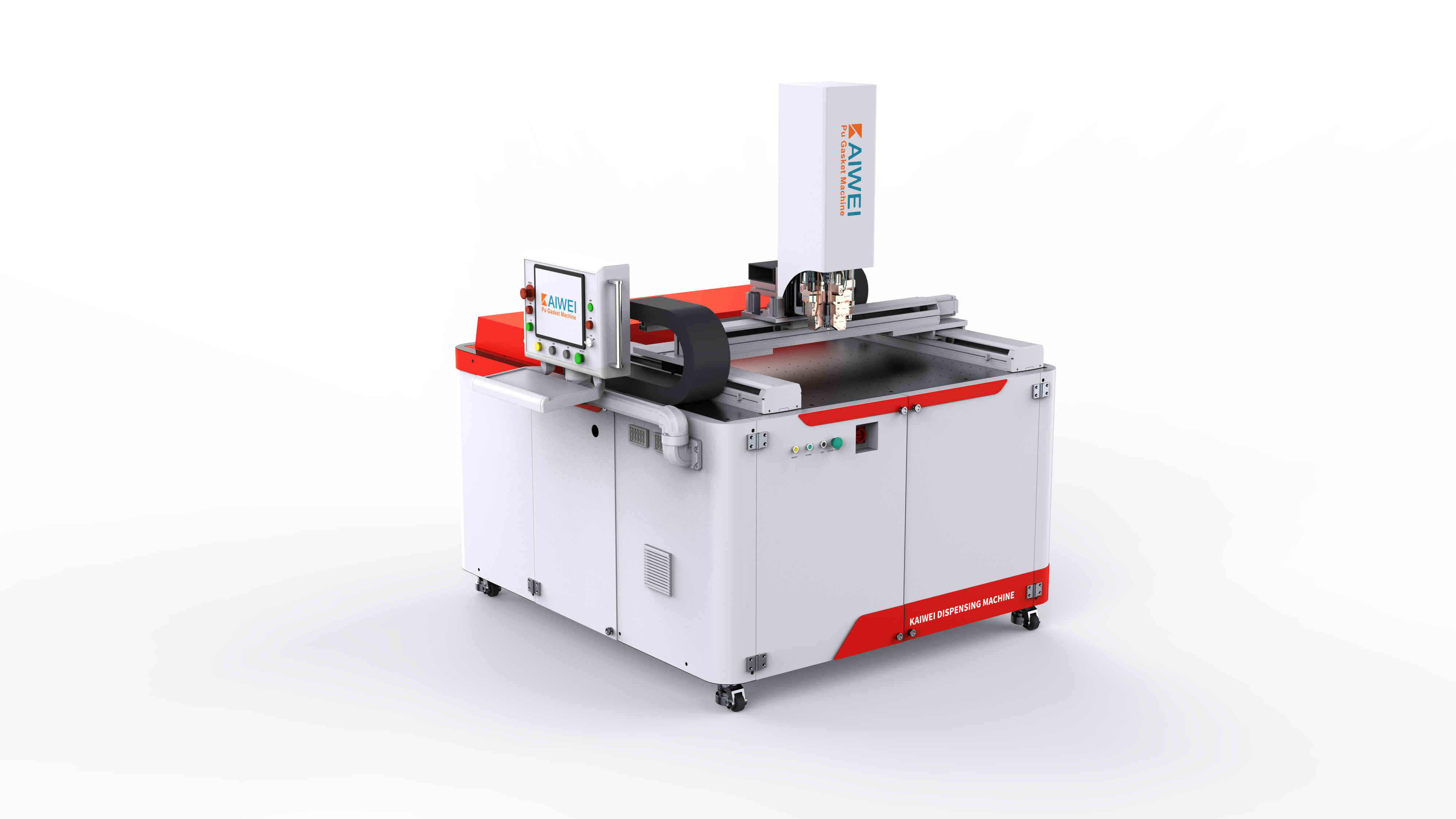

automated foam sealing machine

The automated foam sealing machine represents a revolutionary advancement in industrial sealing technology, designed to streamline manufacturing processes while delivering consistent, high-quality results. This sophisticated equipment integrates cutting-edge automation systems with precision foam dispensing capabilities, making it an essential tool for modern production facilities. The automated foam sealing machine operates through a computerized control system that manages every aspect of the sealing process, from material preparation to final application. At its core, the machine features advanced pneumatic systems that ensure precise foam distribution across various substrate materials. The primary function revolves around creating airtight and watertight seals in diverse applications, including automotive manufacturing, construction materials, electronics housing, and packaging industries. The technological architecture incorporates servo-driven motors that provide exceptional accuracy in foam placement, while integrated sensors monitor temperature, pressure, and flow rates in real-time. These monitoring systems guarantee optimal foam consistency and cure rates throughout the production cycle. The automated foam sealing machine utilizes polyurethane foam formulations that expand and cure to form durable, flexible seals capable of withstanding extreme environmental conditions. Programming interfaces allow operators to customize sealing patterns, adjust foam density, and modify application speeds according to specific product requirements. Multi-axis positioning systems enable the machine to access complex geometries and hard-to-reach areas with remarkable precision. The equipment supports various foam types, including open-cell and closed-cell formulations, each optimized for different sealing applications. Quality control mechanisms include automatic rejection systems that identify and remove defective products, ensuring consistent output standards. The automated foam sealing machine integrates seamlessly with existing production lines through standardized communication protocols and conveyor systems. Safety features include emergency stop functions, protective barriers, and automatic shutdown procedures that protect both operators and equipment. Regular maintenance protocols are simplified through diagnostic systems that provide predictive maintenance alerts and performance analytics.