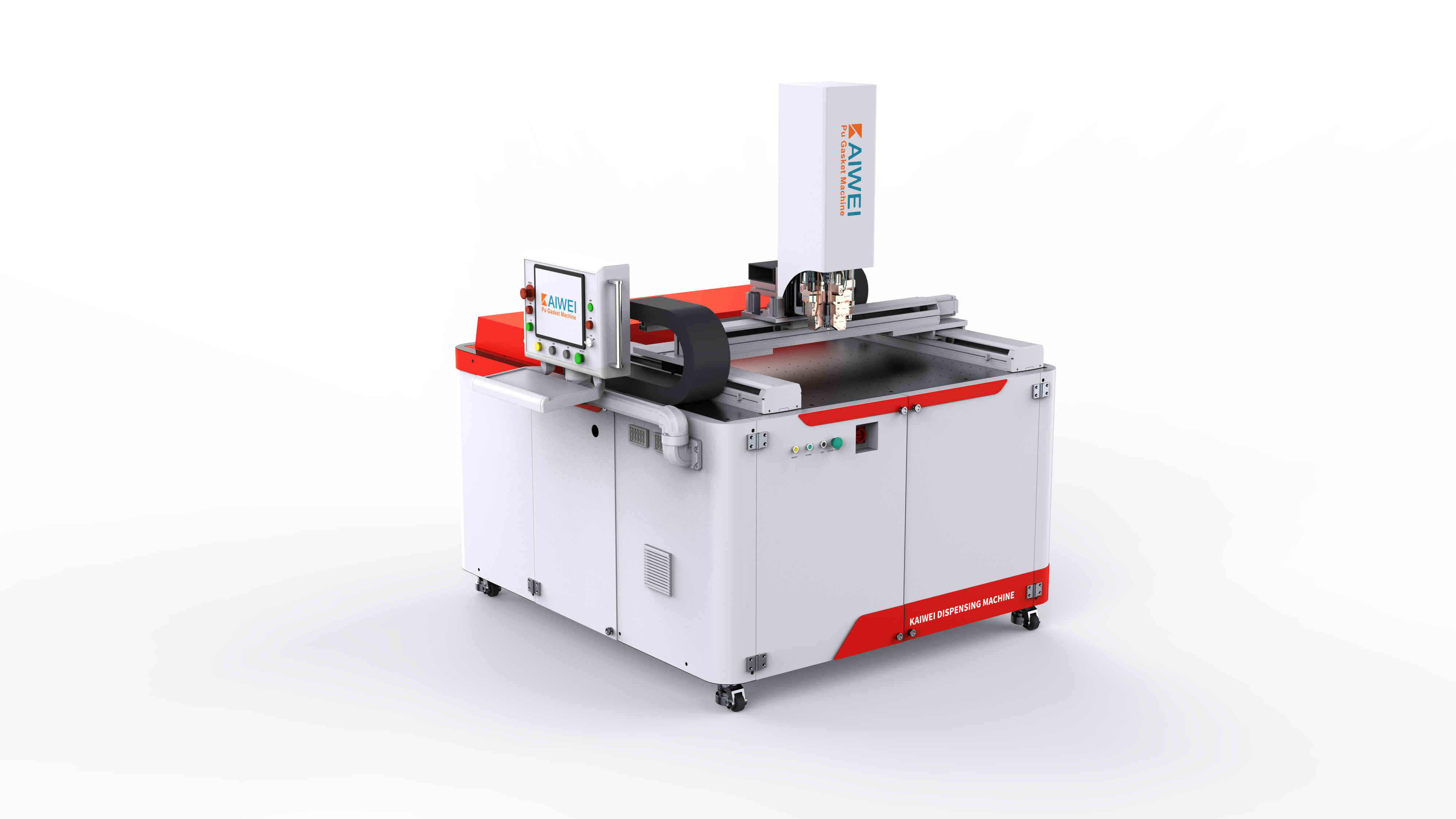

foaminplace sealing equipment

Foaminplace sealing equipment represents a cutting-edge solution for automated foam dispensing and sealing applications across diverse manufacturing environments. This specialized machinery combines precision control systems with advanced dispensing technology to deliver consistent, high-quality foam seals for automotive, aerospace, electronics, and industrial applications. The foaminplace sealing equipment operates through sophisticated metering systems that accurately mix multi-component foam materials, ensuring optimal chemical reactions and uniform foam expansion. These systems feature programmable logic controllers that manage temperature regulation, pressure monitoring, and flow rate adjustment with exceptional accuracy. The equipment incorporates heated hoses and dispensing heads to maintain optimal material temperatures throughout the application process, preventing premature curing and ensuring smooth material flow. Modern foaminplace sealing equipment includes user-friendly touchscreen interfaces that allow operators to store multiple program recipes, monitor real-time performance data, and make precise adjustments during production runs. The robust construction features corrosion-resistant components designed to handle aggressive chemical formulations while maintaining long-term reliability. These machines support various foam types including polyurethane, silicone, and specialized compounds engineered for specific sealing requirements. The equipment's modular design enables easy integration into existing production lines while accommodating custom tooling and fixturing requirements. Advanced foaminplace sealing equipment incorporates quality control features such as weight monitoring, cure time tracking, and automated reject systems to maintain consistent output standards. Environmental controls including fume extraction and containment systems ensure safe operation while meeting workplace safety regulations. The technology supports both manual and fully automated operation modes, providing flexibility for different production volumes and complexity requirements.