The Evolution of Industrial Sealing Technology in Modern Manufacturing

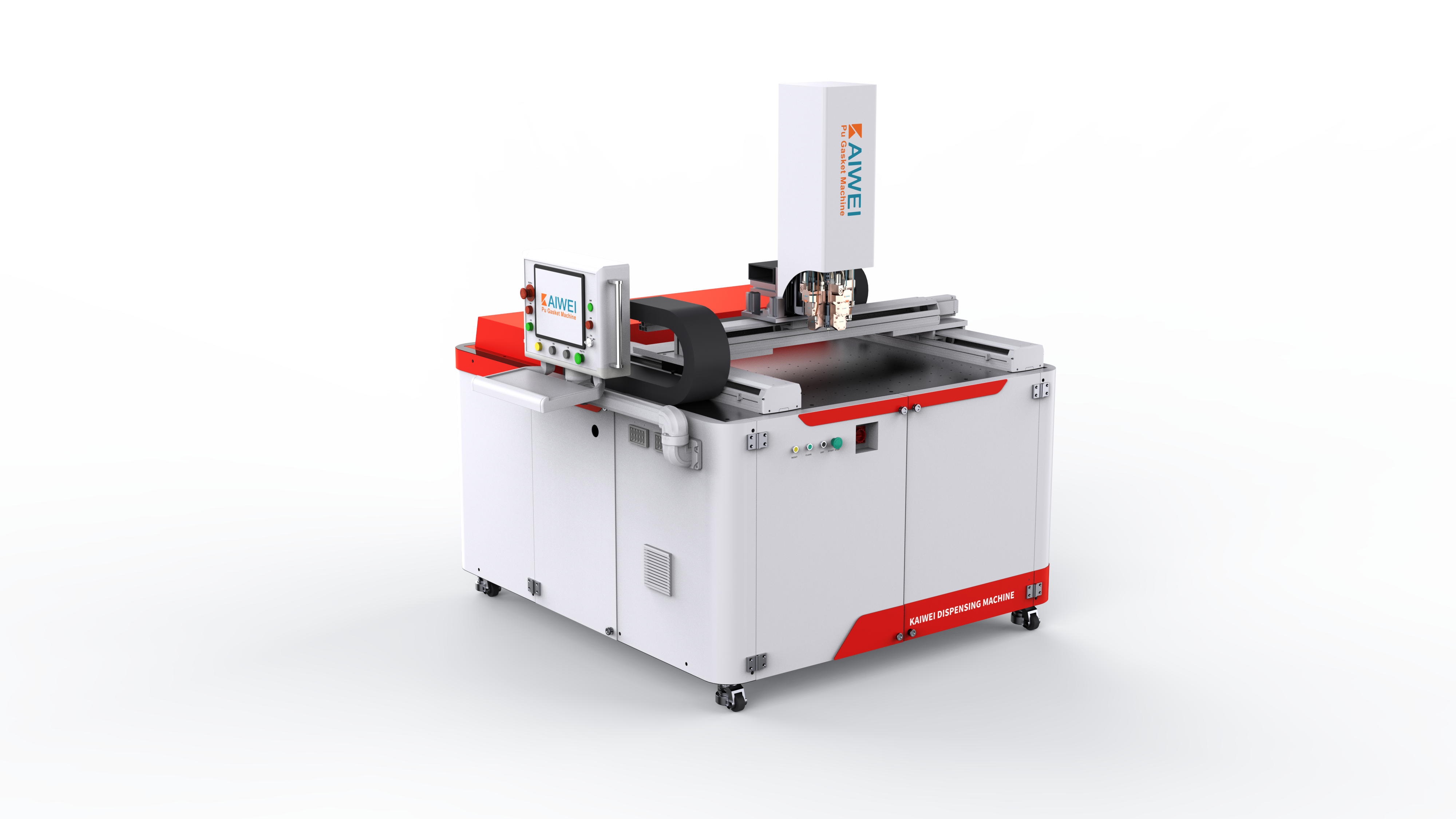

Manufacturing processes in the automotive and electrical industries have undergone significant transformations over the past decades, with PU gasket sealing machines emerging as the cornerstone of precision sealing applications. These advanced systems have revolutionized how manufacturers approach gasketing and sealing solutions, offering unprecedented accuracy, consistency, and efficiency in production processes.

The adoption of PU gasket sealing machines has grown exponentially, particularly in industries where reliability and precision are paramount. These sophisticated machines have become indispensable tools for manufacturers who need to meet stringent quality standards while maintaining high production volumes. The technology behind these systems continues to evolve, incorporating innovative features that address the complex demands of modern manufacturing environments.

Advanced Features and Capabilities of Modern PU Gasket Systems

Precision Control and Automation

Modern PU gasket sealing machines incorporate state-of-the-art control systems that ensure precise material dispensing and application. The automated processes eliminate human error and maintain consistent quality across production runs. These systems feature advanced sensors and monitoring capabilities that continuously adjust parameters such as flow rate, pressure, and temperature to achieve optimal results.

The integration of programmable logic controllers (PLCs) and sophisticated software enables manufacturers to store and recall specific production recipes, making it easier to switch between different product specifications. This level of automation not only improves productivity but also reduces material waste and ensures repeatable quality in gasket formation.

Material Compatibility and Versatility

One of the most significant advantages of PU gasket sealing machines is their ability to work with various polyurethane formulations. This versatility allows manufacturers to select the most appropriate material properties for specific applications, whether it's chemical resistance, temperature tolerance, or compression set characteristics.

The machines can handle different viscosities and cure times, making them suitable for a wide range of sealing applications. From automotive door seals to electrical enclosure gaskets, these systems can be configured to deliver optimal results across diverse manufacturing requirements.

Economic Benefits and Return on Investment

Operational Cost Reduction

Implementing PU gasket sealing machines leads to substantial cost savings in manufacturing operations. The automated application process minimizes material waste, reduces labor costs, and decreases the likelihood of defective products. These machines achieve higher production rates while maintaining consistent quality, resulting in improved operational efficiency.

The precision dispensing capabilities ensure that exactly the right amount of material is used for each application, eliminating excess waste and reducing material costs. Additionally, the automated nature of these systems means fewer workers are needed to maintain production levels, leading to significant labor cost savings over time.

Quality Improvement and Warranty Benefits

The superior accuracy and consistency of PU gasket sealing machines directly translate to improved product quality and reduced warranty claims. The precise control over gasket formation ensures better sealing performance, leading to fewer field failures and customer complaints. This enhanced reliability helps manufacturers maintain their reputation and reduce long-term warranty-related expenses.

Manufacturing facilities using these machines report significant reductions in quality control issues and customer returns. The consistent gasket profiles and reliable sealing properties contribute to extended product lifespans and improved customer satisfaction.

Industry-Specific Applications and Benefits

Automotive Manufacturing Requirements

In the automotive industry, PU gasket sealing machines play a crucial role in producing various components, from door seals to electrical enclosures. The machines meet the demanding requirements of automotive manufacturing, including precise material application, fast cure times, and the ability to handle complex geometries.

These systems are particularly valuable in producing weather-resistant seals for vehicle components, ensuring protection against moisture, dust, and environmental contaminants. The consistency and reliability of machine-applied gaskets contribute to improved vehicle quality and longevity.

Electrical Industry Applications

For electrical manufacturers, PU gasket sealing machines provide essential solutions for creating reliable seals in enclosures and junction boxes. The precise application of gasketing materials ensures proper protection of electrical components from moisture, dust, and other environmental factors that could compromise functionality.

The machines' ability to create consistent, high-quality seals is particularly important in maintaining IP ratings and meeting regulatory requirements for electrical enclosures. This precision contributes to the overall safety and reliability of electrical products.

Future Trends and Technological Advancements

Integration with Industry 4.0

The future of PU gasket sealing machines lies in their integration with Industry 4.0 principles. Advanced connectivity features enable real-time monitoring, predictive maintenance, and data analytics capabilities. These smart features help manufacturers optimize their processes and maintain peak performance levels.

Emerging technologies such as artificial intelligence and machine learning are being incorporated into newer models, enabling more sophisticated quality control and process optimization. These advancements continue to enhance the capabilities and efficiency of gasket sealing operations.

Sustainable Manufacturing Practices

Modern PU gasket sealing machines are increasingly designed with sustainability in mind. Manufacturers are focusing on energy efficiency, reduced material waste, and the use of eco-friendly materials. These environmental considerations are becoming increasingly important as industries strive to reduce their carbon footprint.

The precision control offered by these machines helps minimize material waste and energy consumption, contributing to more sustainable manufacturing practices. Additionally, newer machine designs incorporate features that support the use of environmentally friendly polyurethane formulations.

Frequently Asked Questions

What maintenance requirements do PU gasket sealing machines have?

PU gasket sealing machines require regular maintenance, including cleaning of dispensing components, calibration of sensors, and inspection of moving parts. Most manufacturers recommend daily cleaning procedures and scheduled maintenance checks to ensure optimal performance and longevity of the equipment.

How long does it take to train operators on PU gasket sealing machines?

Operator training typically takes between one to two weeks, depending on the complexity of the machine and applications. Most modern systems feature user-friendly interfaces and automated processes that make training relatively straightforward. Manufacturers often provide comprehensive training programs and ongoing support.

What factors should be considered when selecting a PU gasket sealing machine?

Key considerations include production volume requirements, material compatibility, desired automation level, available floor space, and budget constraints. Other important factors include the complexity of gasket designs, required cure times, and the need for specific features such as vision systems or quality control capabilities.

How do PU gasket sealing machines handle different material viscosities?

Modern PU gasket sealing machines are equipped with adjustable parameters and specialized dispensing systems that can accommodate various material viscosities. They feature temperature control systems, pressure regulation, and flow rate adjustments to ensure optimal material handling and application regardless of viscosity levels.